Cross-shaped section column of corrugated steel web-concrete filled steel tube flange combination

A corrugated steel web and concrete-filled steel tube technology, which is applied to columns, piers, pillars, etc., can solve the problems of poor fire resistance of pure steel structures, increase the overall cost of the project, and lose the resistance of steel columns. and fire prevention, reduce the comprehensive cost of the project, and improve the effect of stable bearing capacity

Inactive Publication Date: 2015-02-04

NANJING UNIV OF TECH

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to ensure the local stability of the web and meet the web height-to-thickness ratio limit specified in the "Code for Design of Steel Structures", it is usually necessary to increase the web thickness, which will lead to increased steel consumption, increased construction costs, and increased engineering costs. comprehensive cost of

What's more, when the bending moment effect is large, the pressure on the flange of the steel column is too large, which may enter the failure state prematurely, causing the steel column to quickly lose its resistance; at the same time, the fire resistance of pure steel structures is relatively poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0028] Usually steel pipes, corrugated steel webs and their welding are completed in the factory; pouring concrete into the steel pipes is completed at the construction site.

[0029] The basic production procedure is: making corrugated steel webs → making steel pipes → welding → transporting to the construction site → hoisting in place → pouring concrete into the steel pipes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

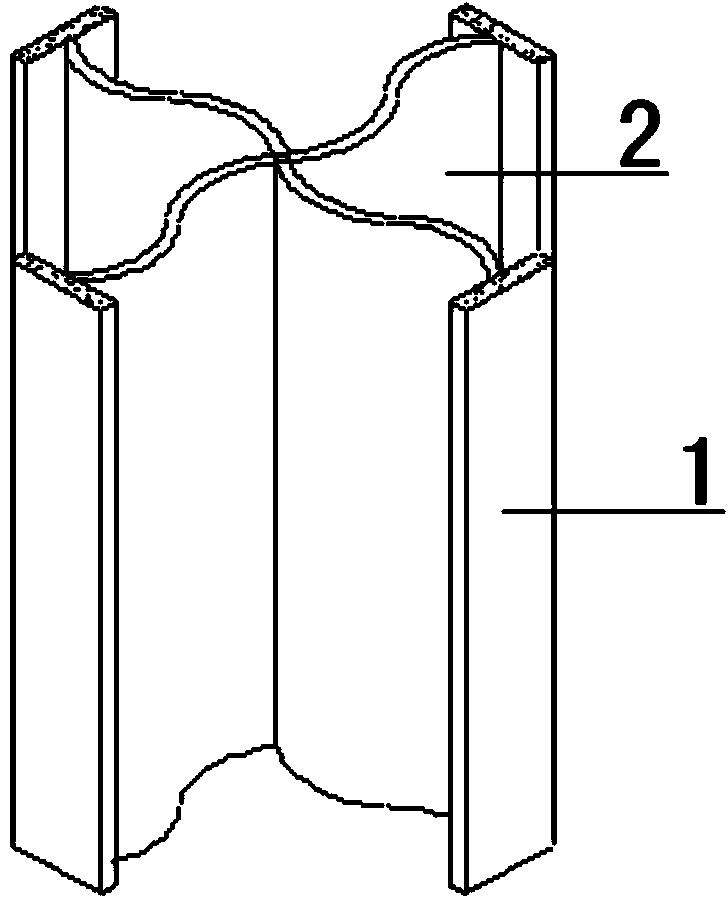

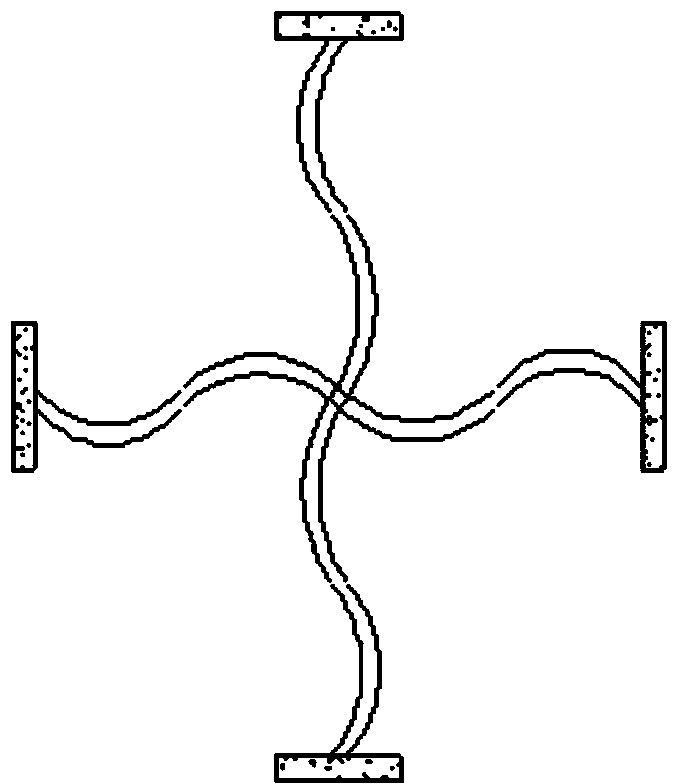

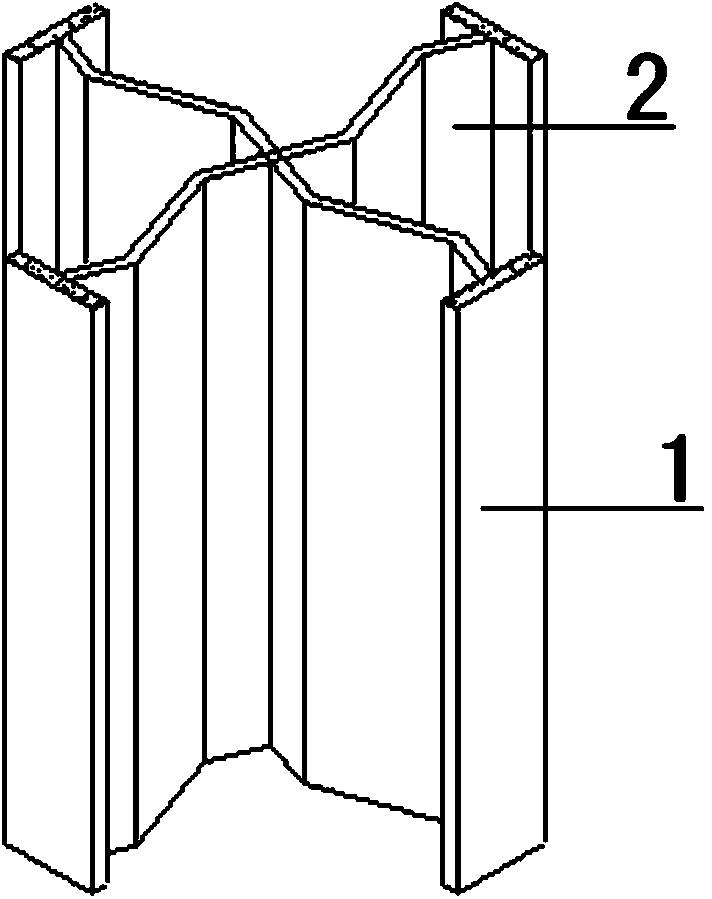

The invention discloses a cross-shaped section column of a corrugated steel web-concrete filled steel tube flange combination. The cross-shaped section column comprises three steel webs and four flanges, wherein the three steel webs are connected together to form a cross-shaped component, wherein the cross-shaped component is connected to the four flanges to form a cross-shaped section column; the steel webs are corrugated; the corrugated steel webs have the form of curvilinear figure, folded line shape or trapezoid; the periodically repeated corrugated edges of the corrugated steel webs are perpendicular to the length direction of the component; the non-corrugated edges of the corrugated steel webs are respectively welded with the width central points of the four flanges; the flanges are concrete filled steel tube flanges including steel tubes and concrete in the steel tubes; the concrete is self-compacting concrete. According to the cross-shaped section column of the corrugated steel web-concrete filled steel tube flange combination disclosed by the invention, the structural behavior and the fire-resistant performance of the cross-shaped section steel column of existing flat webs is improved and the comprehensive cost of the project is not increased significantly, so that the cross-shaped section column of a corrugated steel web-concrete filled steel tube flange combination can be applied widely in projects.

Description

technical field [0001] The invention relates to the technical field of a novel building structure, in particular to a cross-section cross-shaped column with a corrugated steel web-concrete steel tube flange composite section. Background technique [0002] The multi-high-rise steel structure is becoming more and more prominent in my country's modernization construction, and is more and more favored by people. In recent years, it has been highly valued by scholars and engineers at home and abroad, and has been widely used. [0003] In the actual project of multi-story steel structure, especially in the transitional layer project connecting the lower reinforced concrete basement and the upper steel structure, the traditional flat web cross-section steel column is usually used, and its cross-section size is usually large, especially is the web dimension. In order to ensure the local stability of the web and meet the web height-to-thickness ratio limit specified in the "Code for...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04C3/34

Inventor 郑廷银殷辰豪苏文

Owner NANJING UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com