Annular equivolume well cementation method

A volume and cementing technology, applied in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve the problems of waste of cement slurry, unqualified cementing quality, and insufficient cement slurry, etc. Low engineering cost, broad market application space, and avoiding the effect of low return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

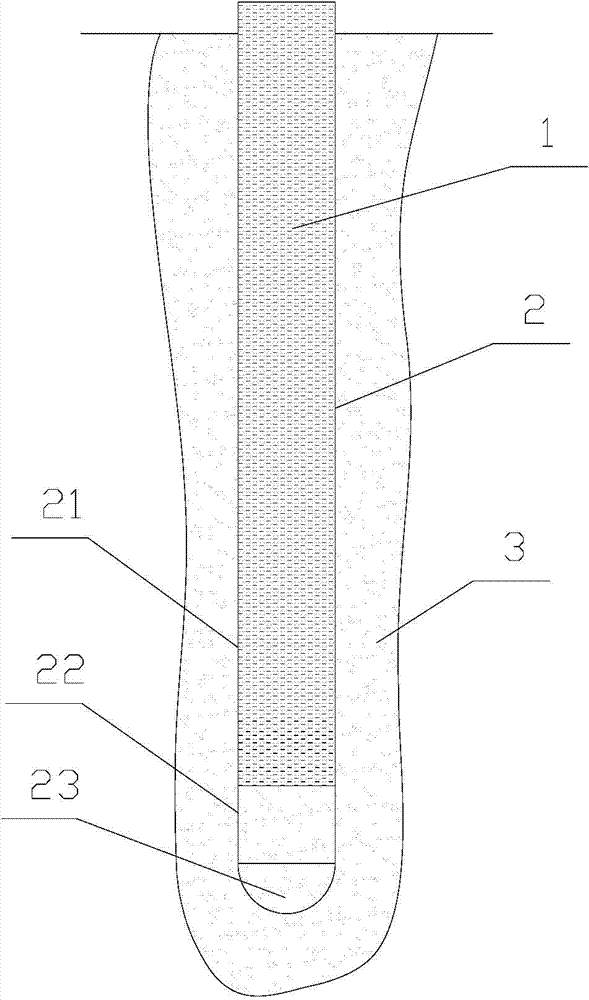

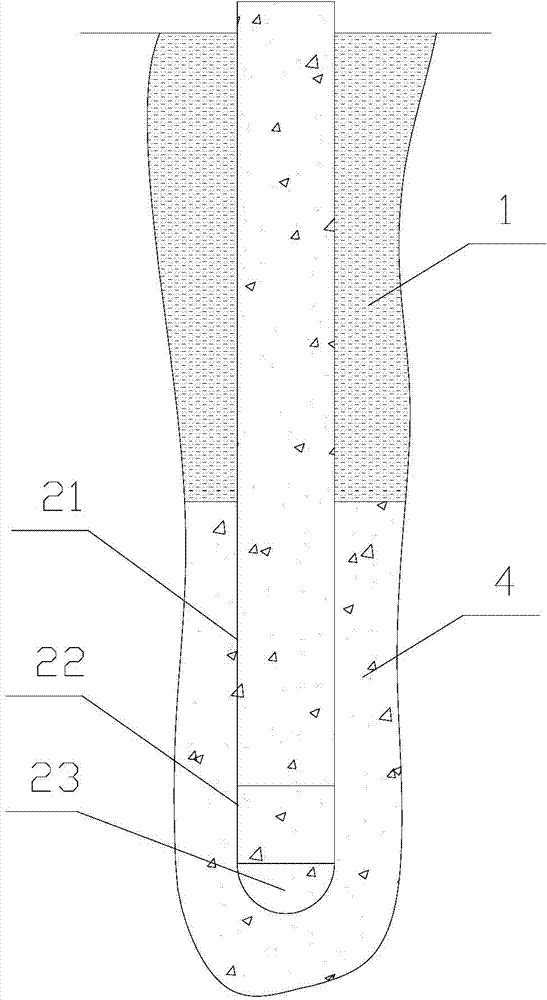

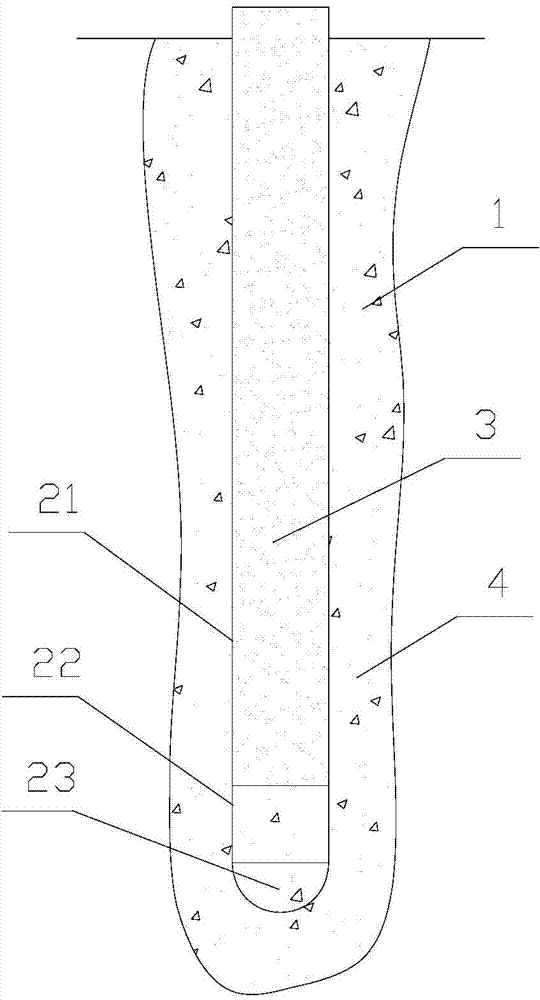

[0032] This embodiment provides a cementing method with equal annular space, which includes the following steps:

[0033] Prepare marker solution:

[0034] Before the cementing construction, the requirements for the performance of the marking fluid are determined according to the previous drilling construction conditions, and the marking fluid is prepared. Because water-based drilling fluid was used in the previous drilling construction, and the requirements for suspended cuttings and solid particles were high, the marking fluid in this example was composed of water, nonyl polyoxyethylene ether, barite, polypropylene cellulose sodium salt , red fluorescent powder and cinnabar are fully stirred evenly in the circulation tank to obtain a marking liquid, wherein the mass ratio of water, nonyl polyoxyethylene ether, barite, polypropylene cellulose sodium salt, red fluorescent powder and cinnabar is 6.5 :0.4:0.7:0.4:1:1.

[0035] Inject marker fluid:

[0036] Connect the guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com