Non-refrigeration millimeter-wave/infrared lamination detector

A non-refrigerated and detector technology, applied in the direction of electric radiation detectors, antenna supports/mounting devices, radiation element structure, etc., to achieve good conductivity, compact structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

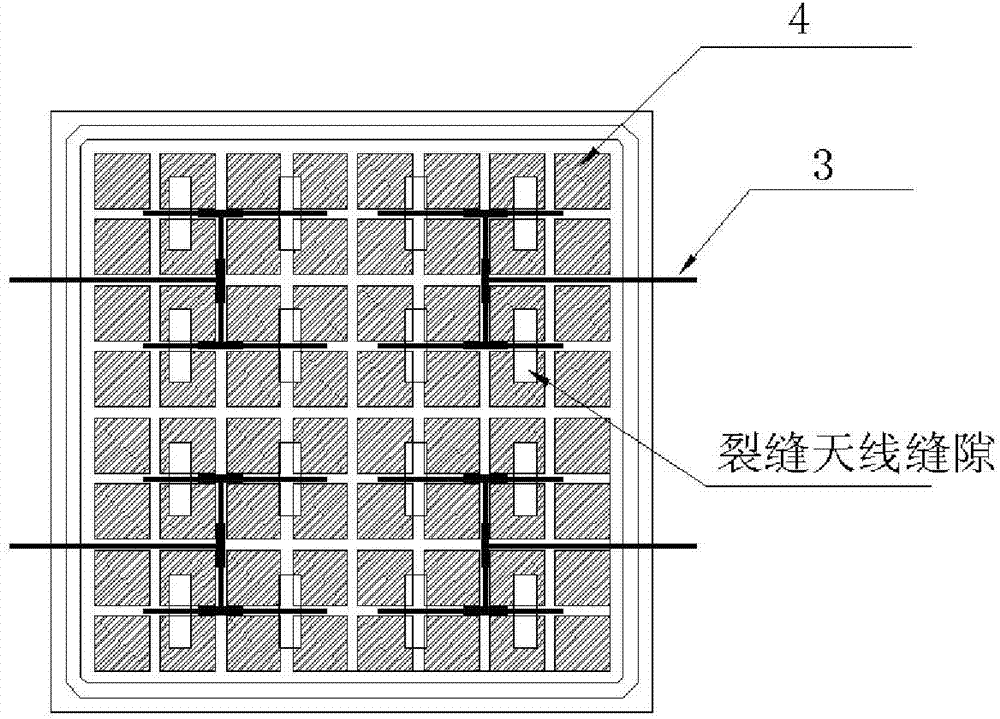

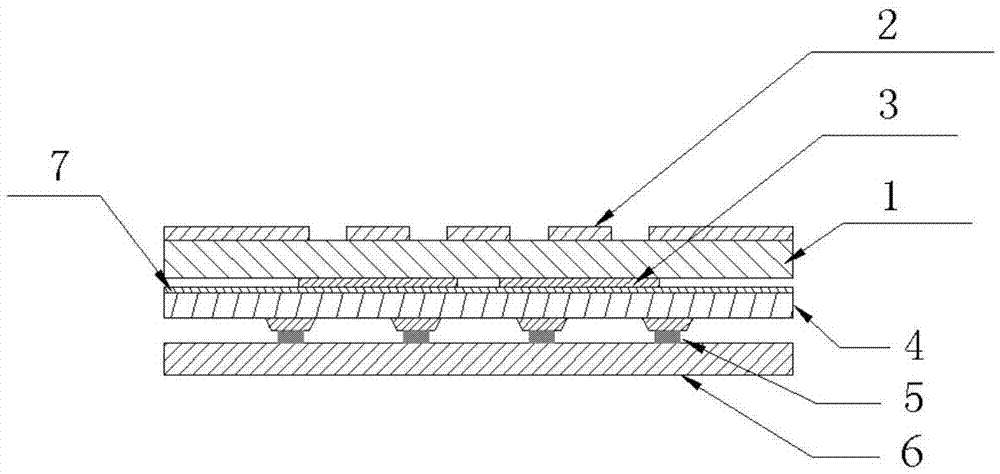

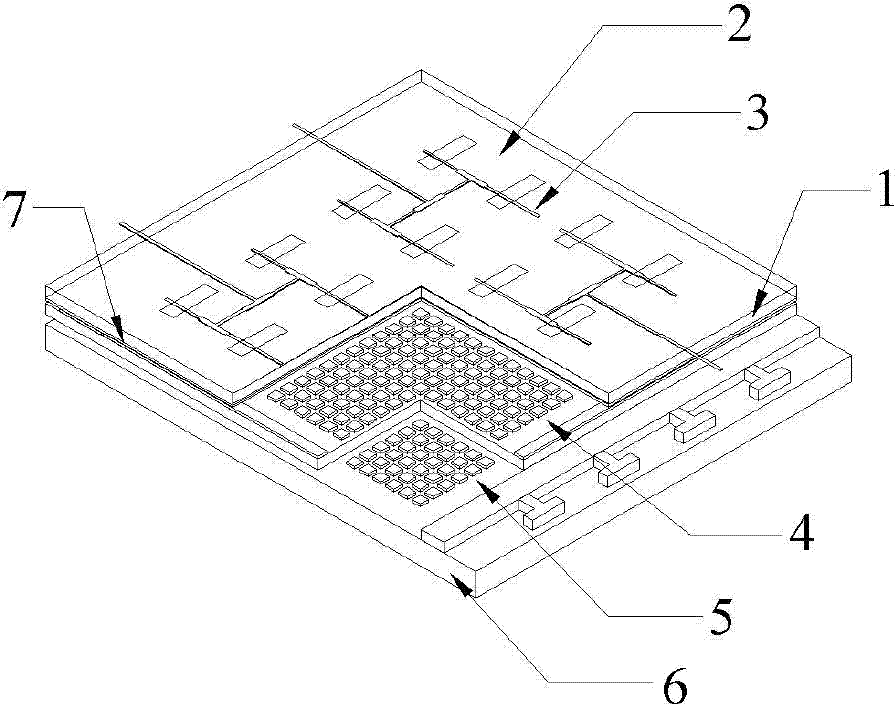

[0019] The invention provides an uncooled millimeter-wave / infrared laminated detector, which includes a microstrip antenna, an uncooled detector element and a readout circuit, and the microstrip antenna is pasted on the back of the uncooled detector element by an adhesive , the front of the uncooled detector element is connected to the readout circuit through the connecting column; one side of the insulating dielectric substrate of the microstrip antenna is a graphene conductive film, and the slits etched on the graphene conductive film are distributed in an array, On the other side of the insulating dielectric substrate, a metal feeder is printed at a position corresponding to each slit on the graphene conductive film.

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] figure 1 , figure 2 Shown is an uncooled millimeter-wave / infrared dual-mode detector, which consists of a microstrip antenna, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com