Patents

Literature

63 results about "Transparent electronics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

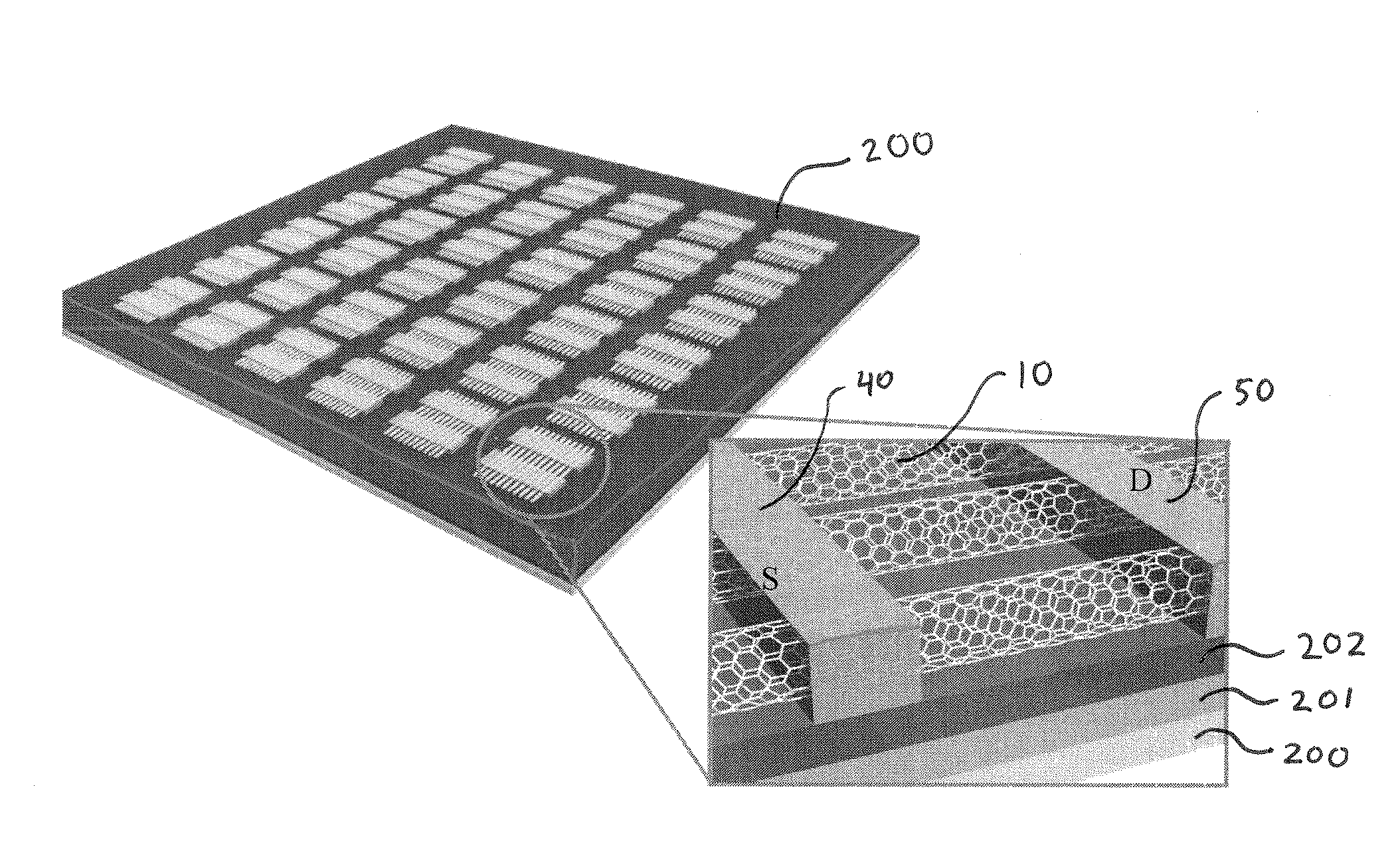

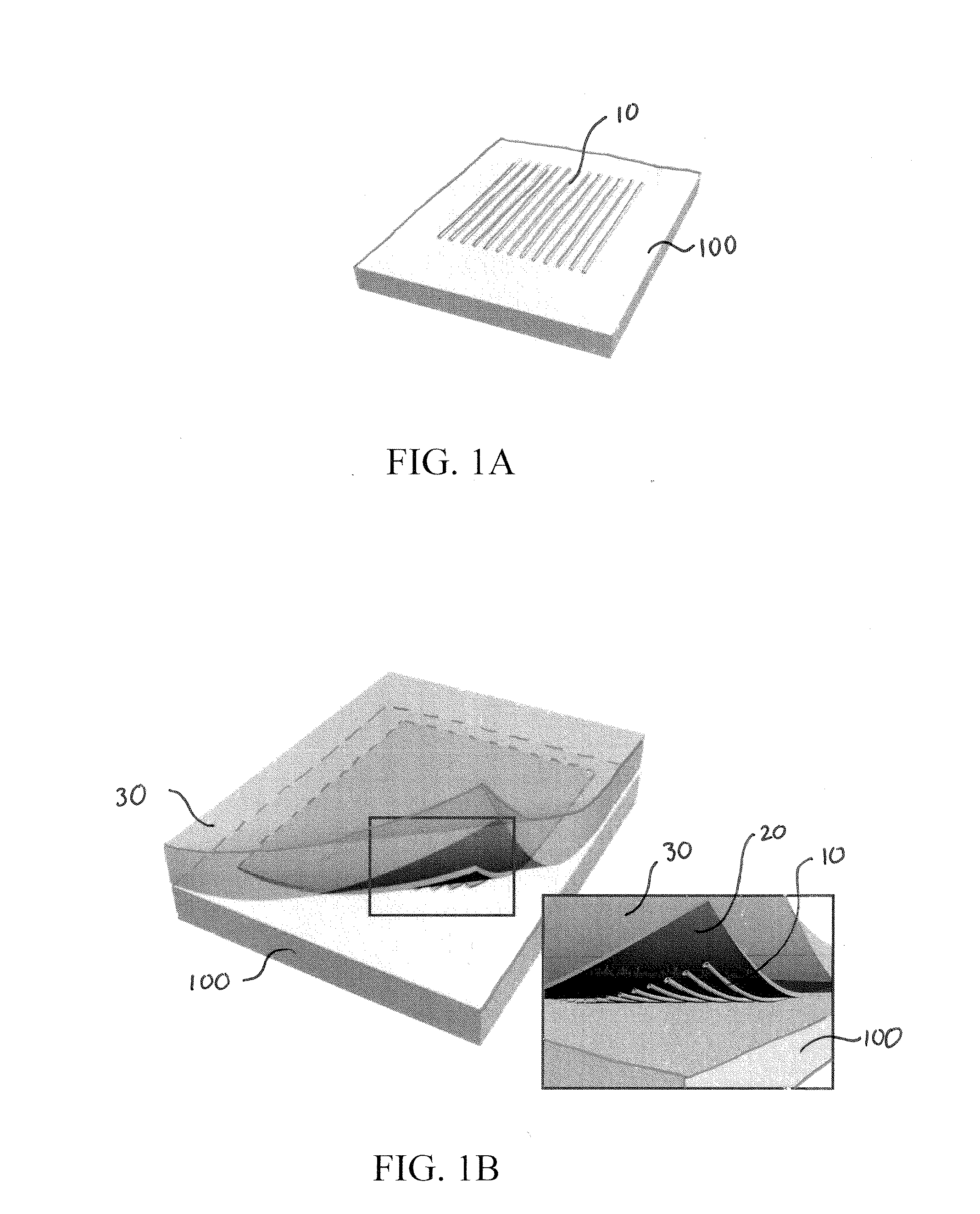

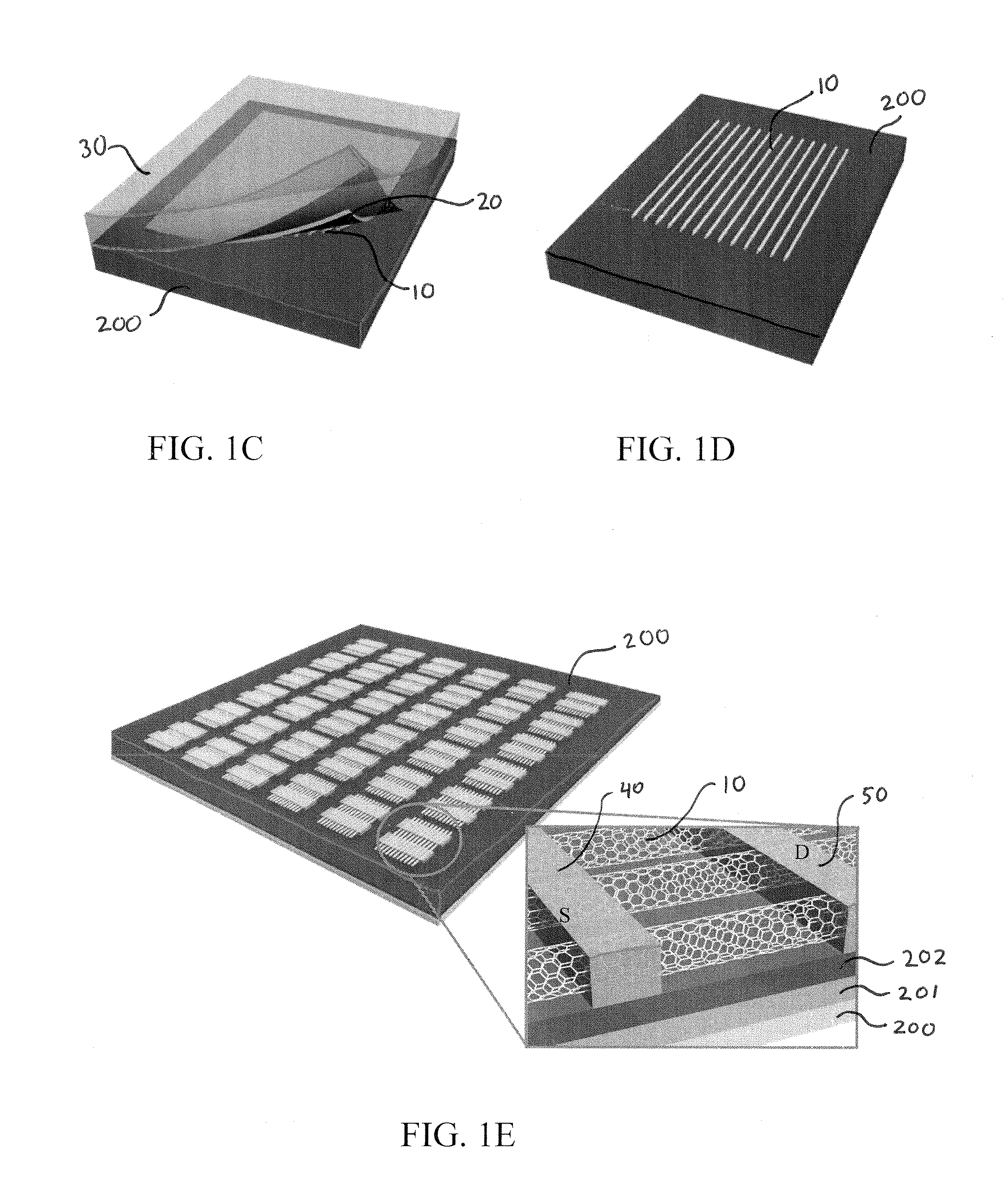

Transparent electronics based on transfer printed carbon nanotubes on rigid and flexible substrates

InactiveUS20100127242A1High carrier mobilityImprove performanceNanoinformaticsSolid-state devicesTransparent electronicsCharge carrier mobility

Methods and devices for transparent electronics are disclosed. According to an embodiment, transparent electronics are provided based on transfer printed carbon nanotubes that can be disposed on both rigid and flexible substrates. Methods are provided to enable highly aligned single-walled carbon nanotubes (SWNTs) to be used in transparent electronics for achieving high carrier mobility while using low-temperature processing. According to one method, highly aligned nanotubes can be grown on a first substrate. Then, the aligned nanotubes can be transferred to a rigid or flexible substrate having pre-patterned gate electrodes. Source and drain electrodes can be formed on the transferred nanotubes. The subject devices can be integrated to provide logic gates and analog circuitry for a variety of applications.

Owner:UNIV OF SOUTHERN CALIFORNIA

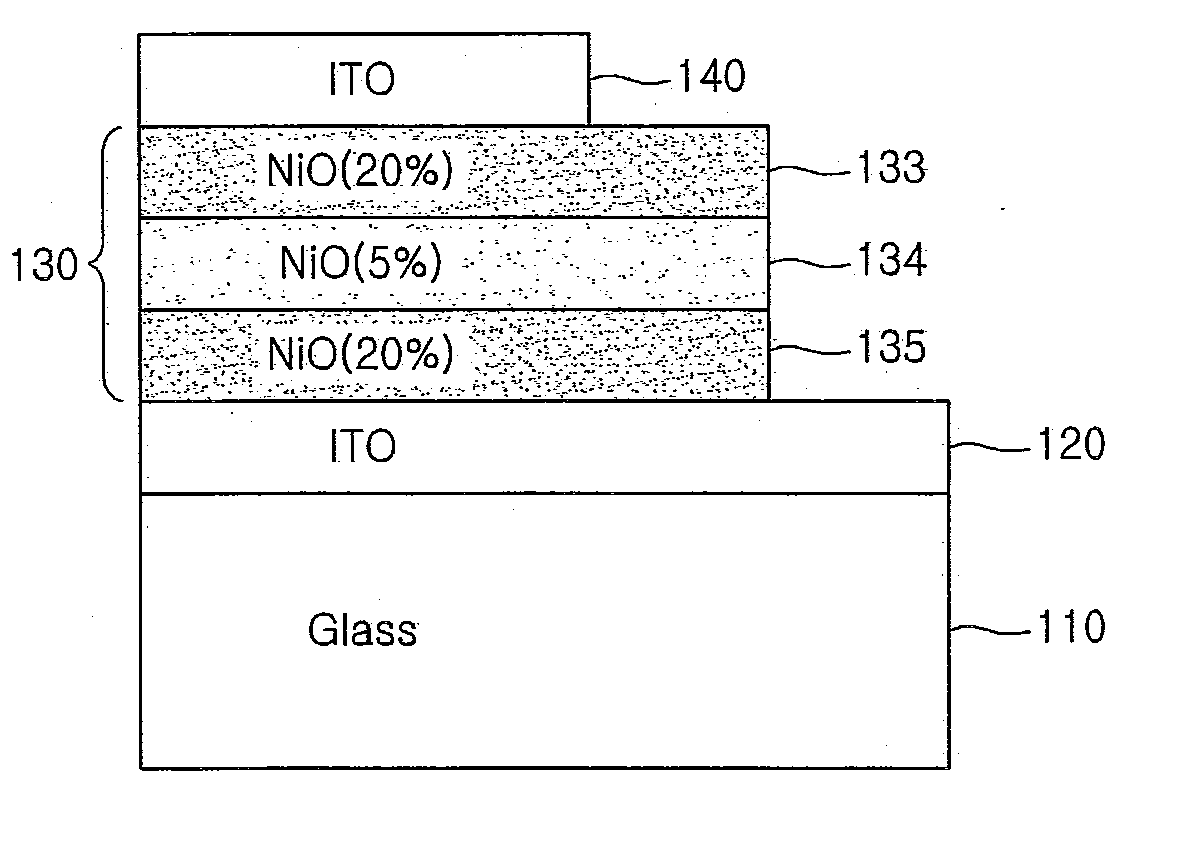

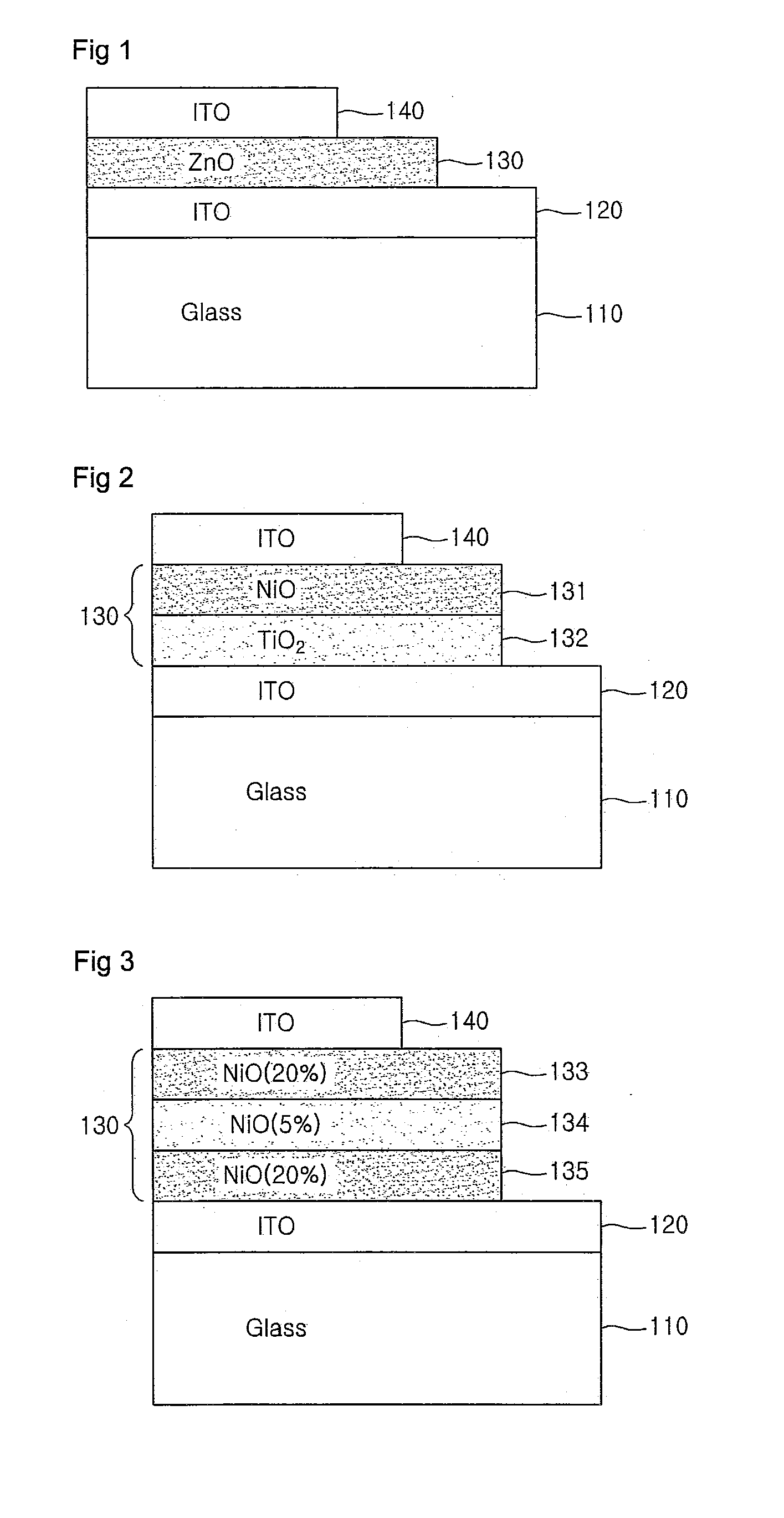

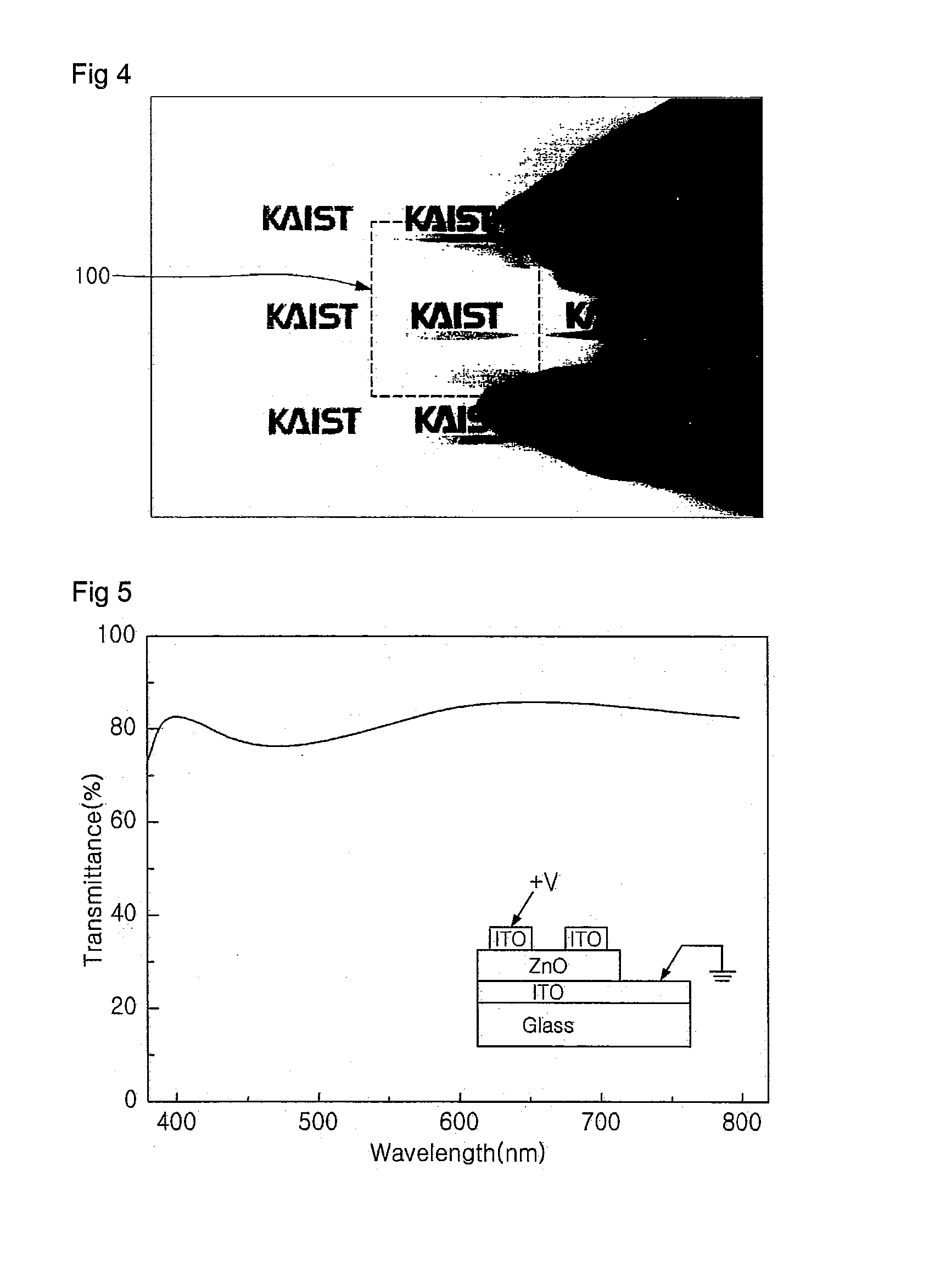

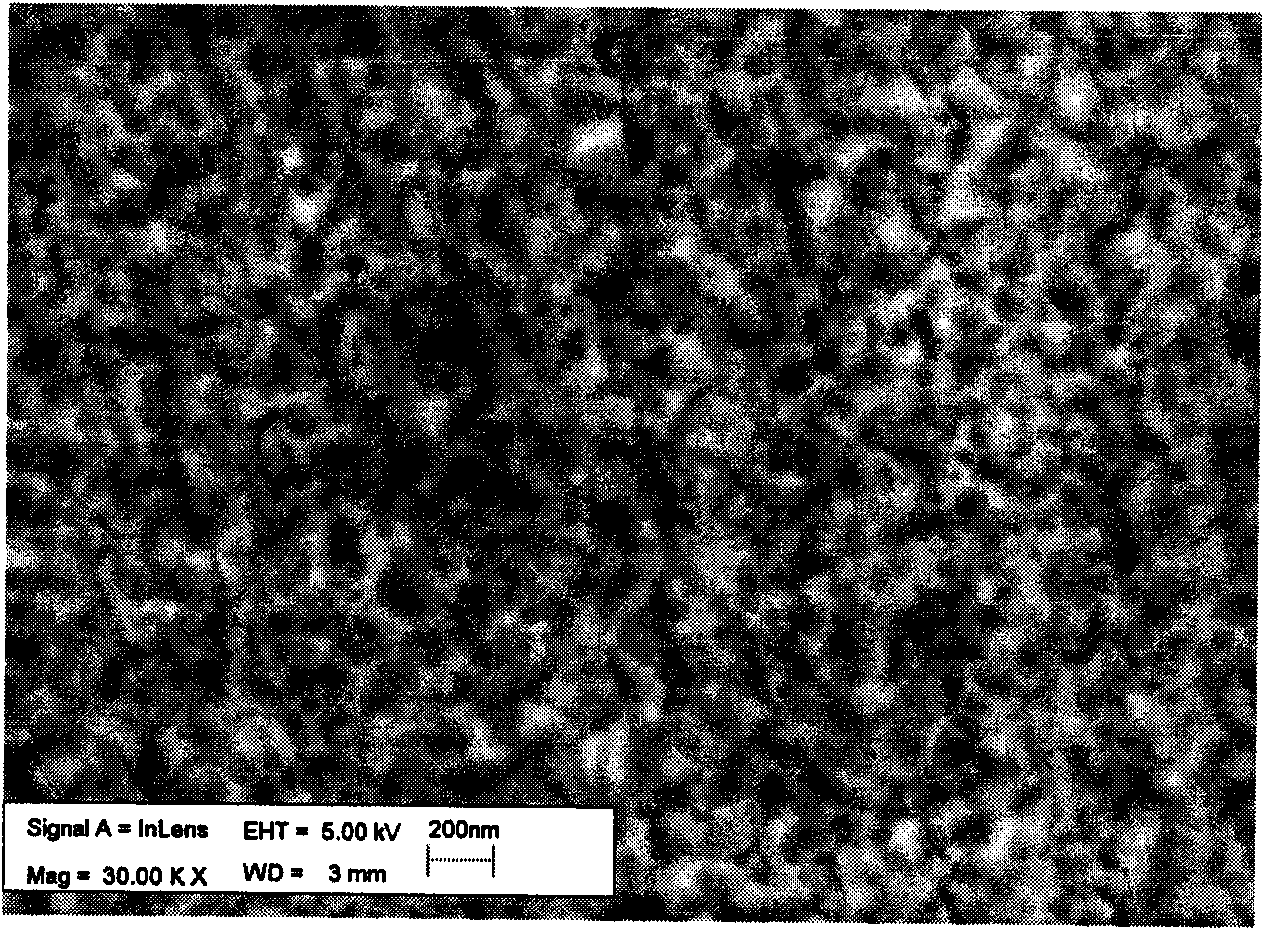

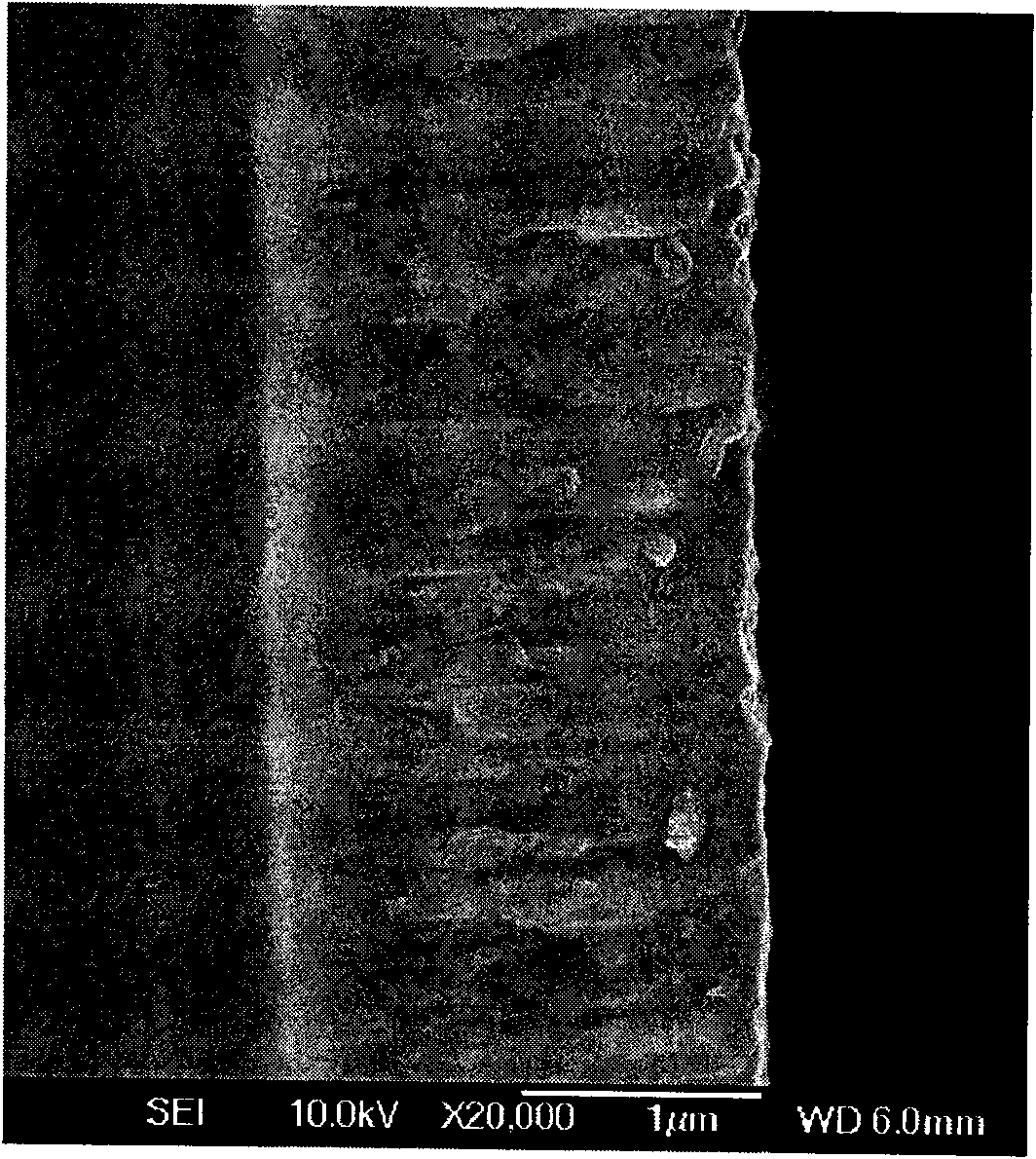

Transparent Memory for Transparent Electronic Device

InactiveUS20120132882A1High transparencyImprove switching characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingTransparent electronicsData store

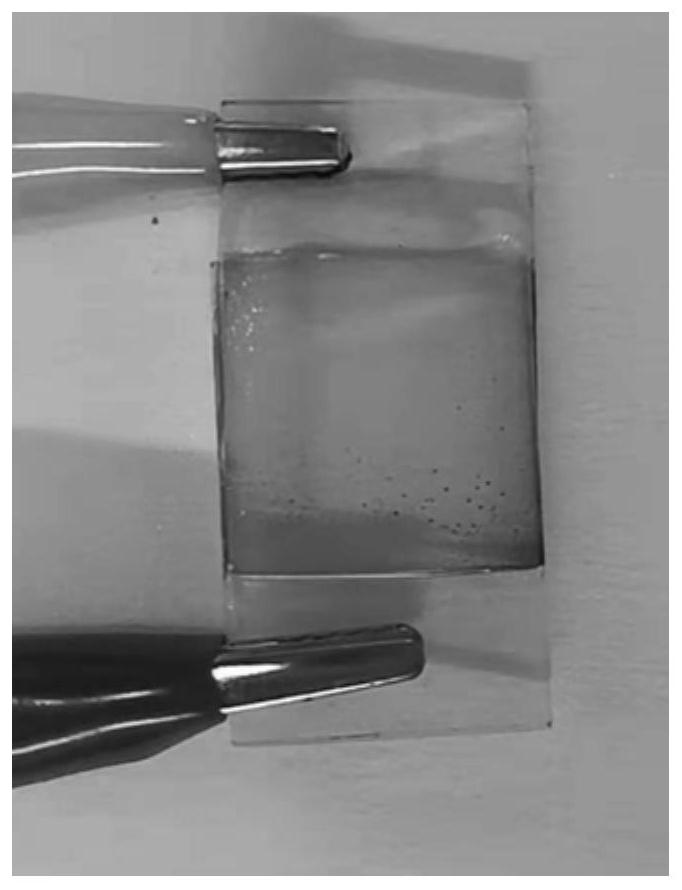

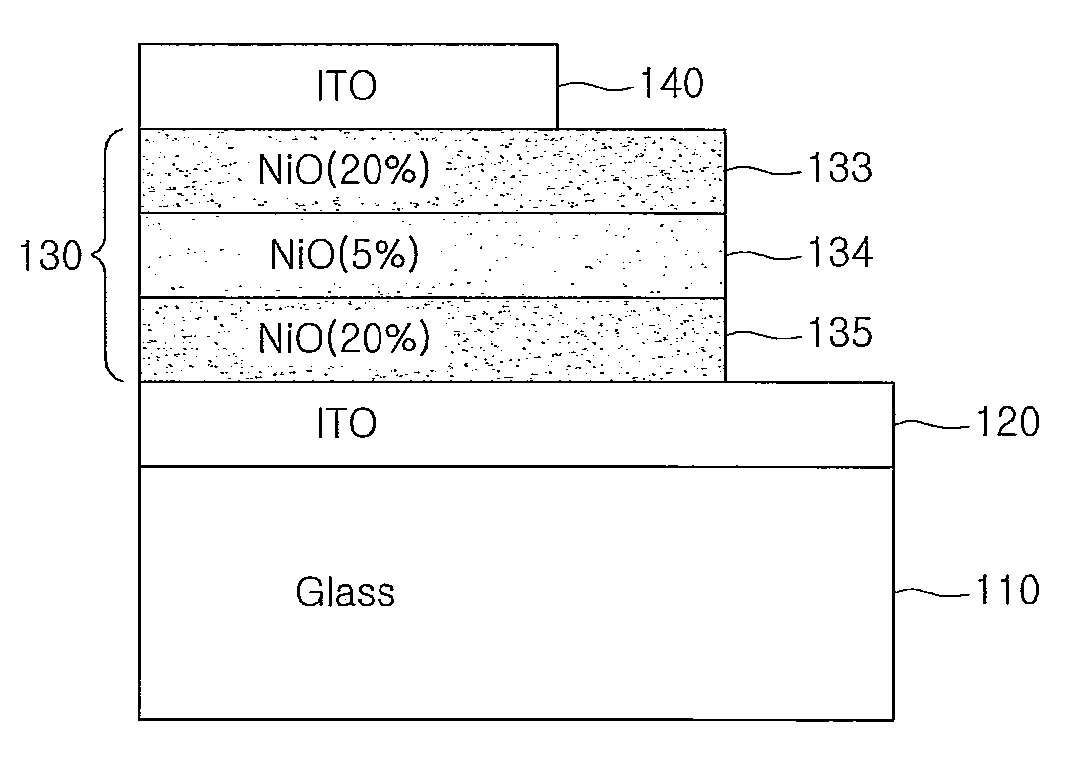

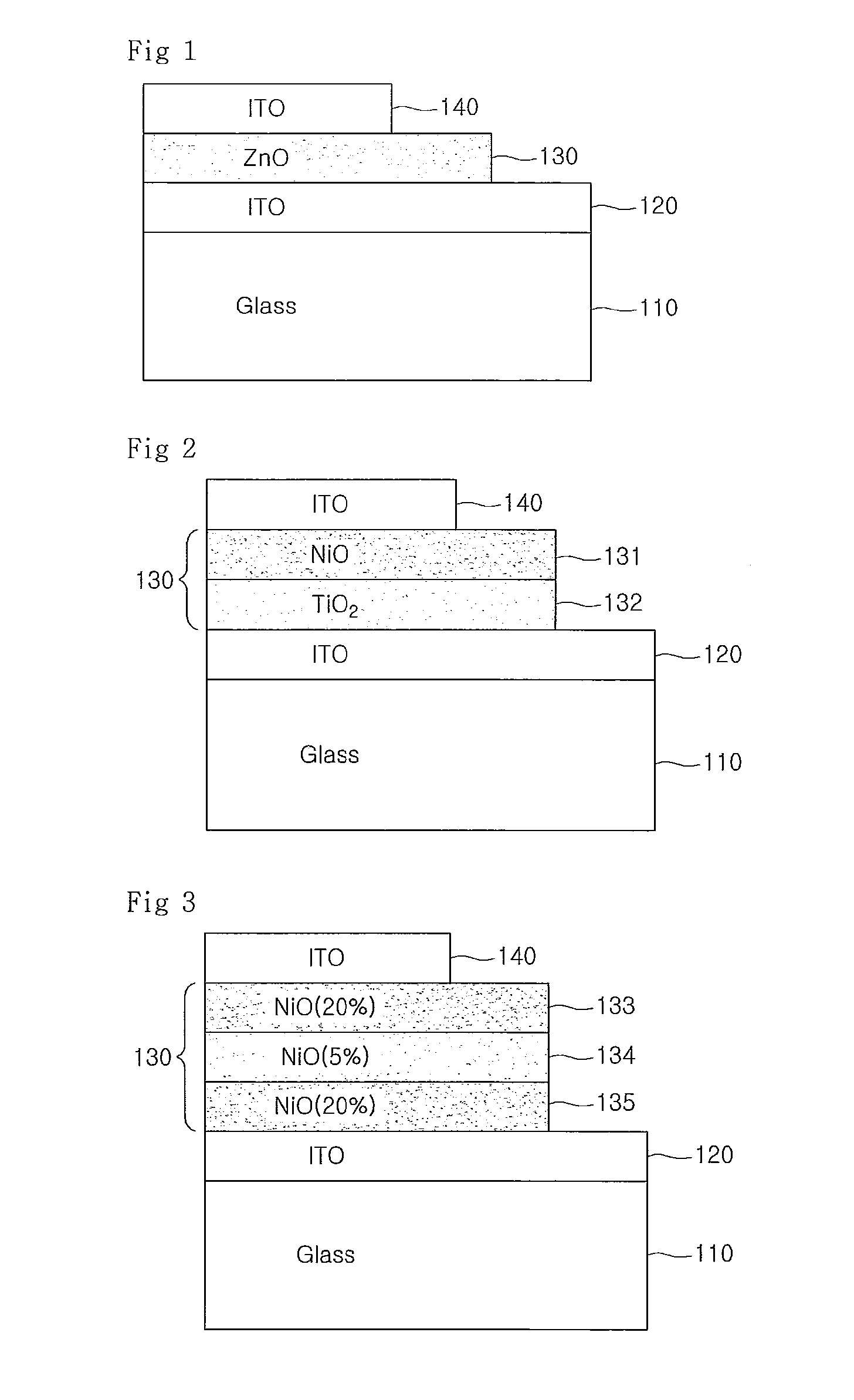

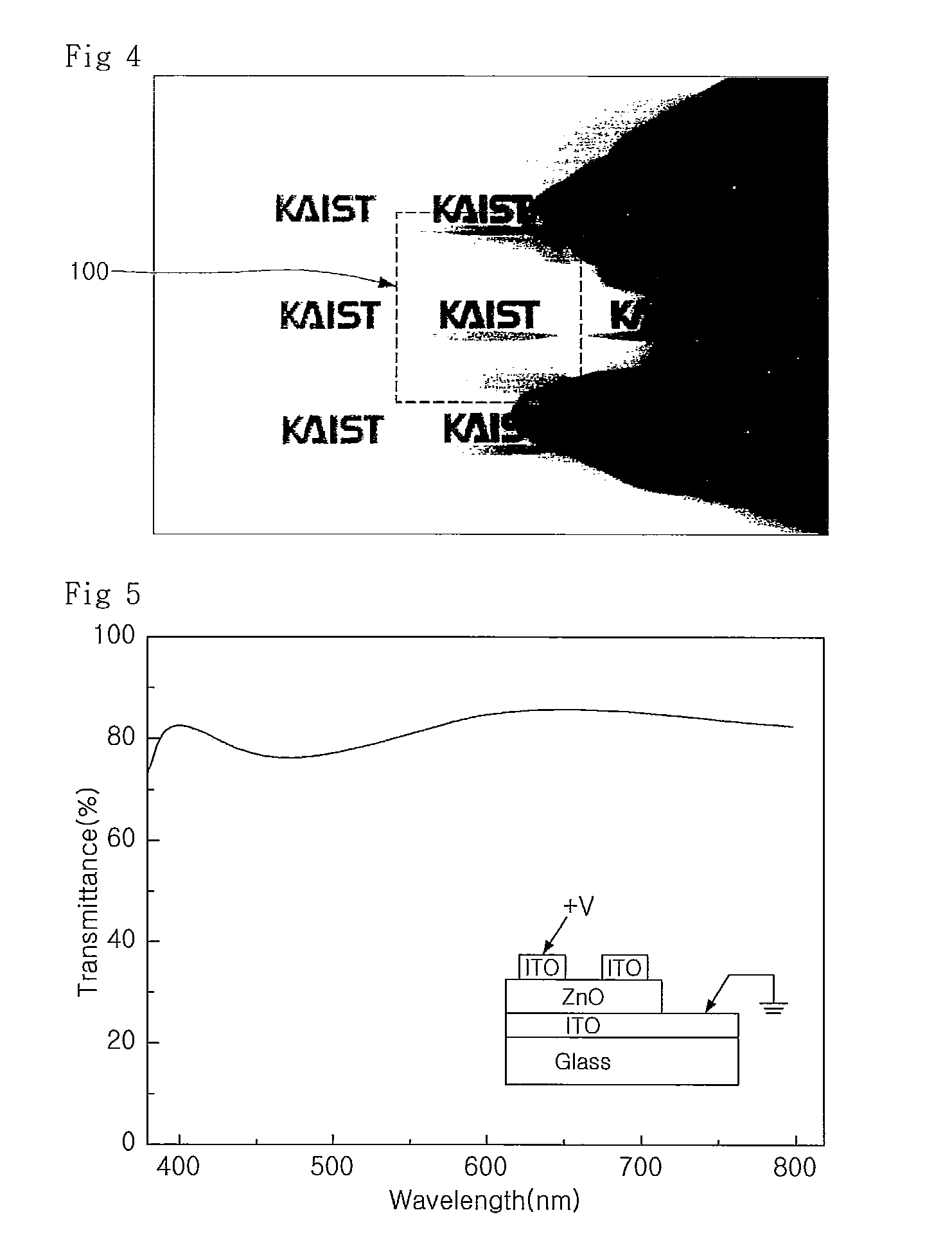

The present invention relates to a transparent memory for a transparent electronic device. The transparent memory includes: a lower transparent electrode layer that is sequentially formed on a transparent substrate, and a data storage region and an upper transparent layer which are made of at least one transparent resistance-variable material layer. The transparent resistance-variable material layer has switching characteristics as a result of the resistance variance caused by the application of a certain voltage between the lower and upper transparent electrode layers. An optical band gap of the transparent resistance-variable material layer is 3 eV or more, and transmittivity of the material layer for visible rays is 80% or more. The invention provides transparent and resistance-variable memory that: has very high transparency and switching characteristics depending on resistance variation at a low switching voltage, and can maintain the switching characteristics thereof after a long time elapses.

Owner:KOREA ADVANCED INST OF SCI & TECH

Multi-element doping n-type zinc-oxide-base transparent conducting film and preparation method thereof

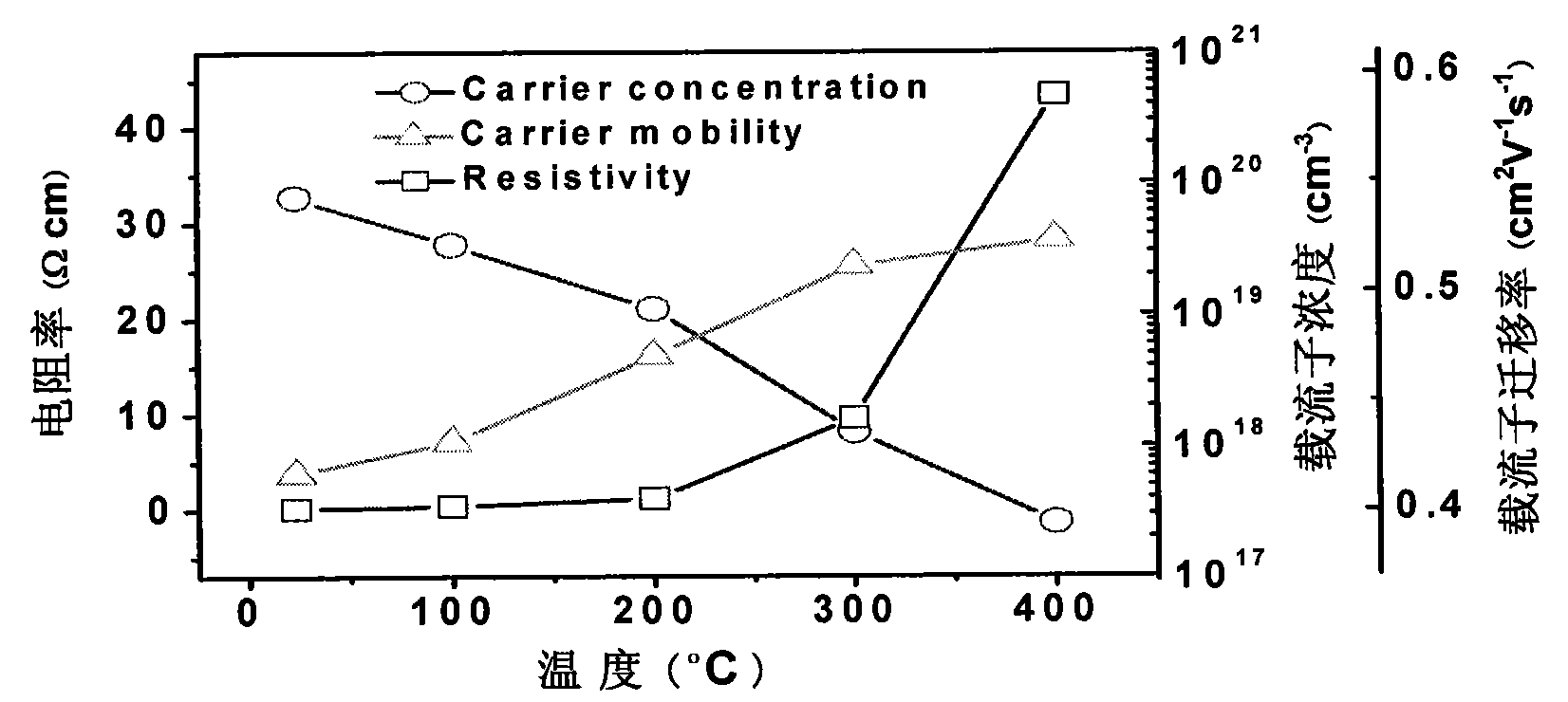

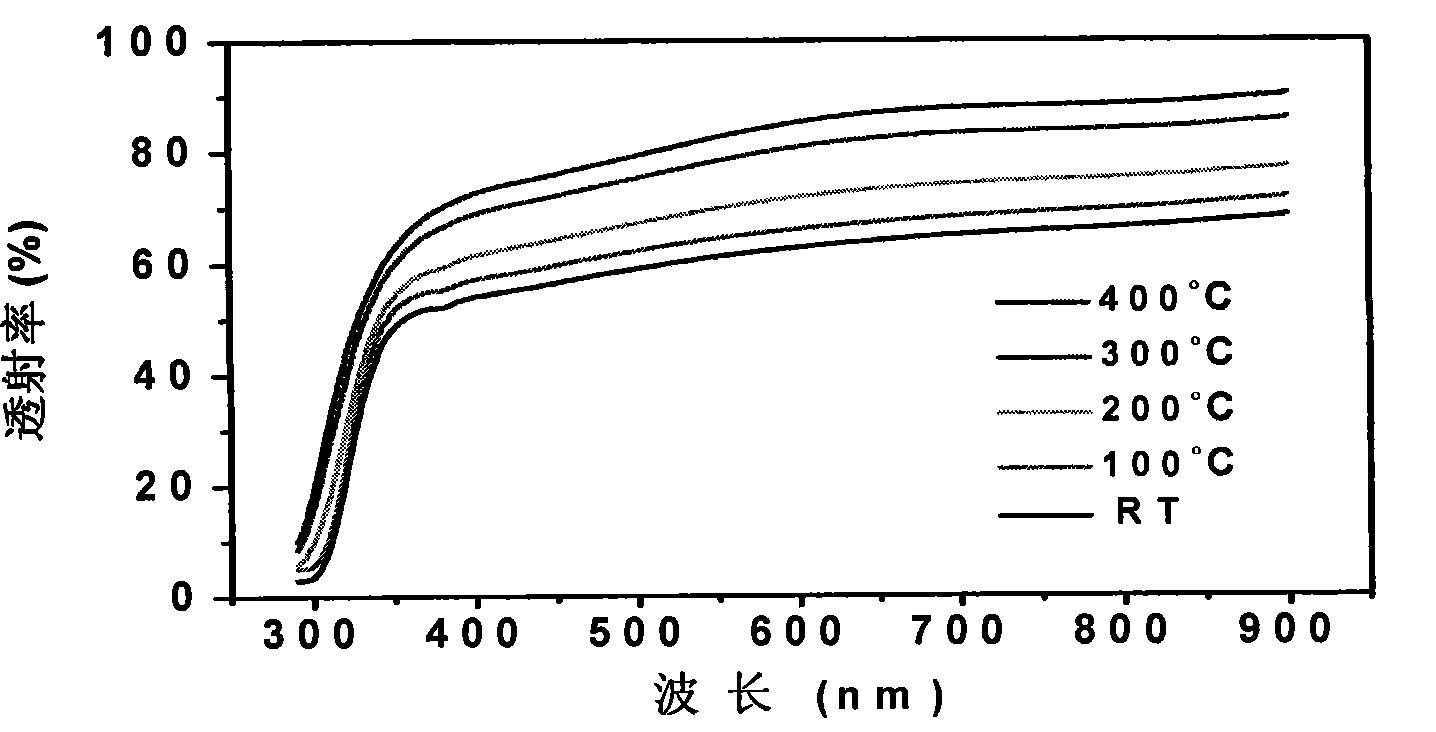

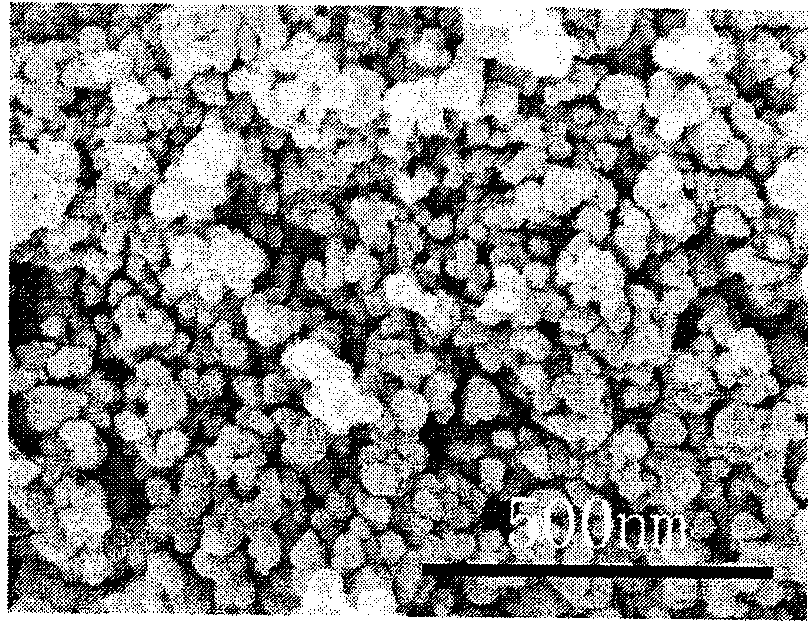

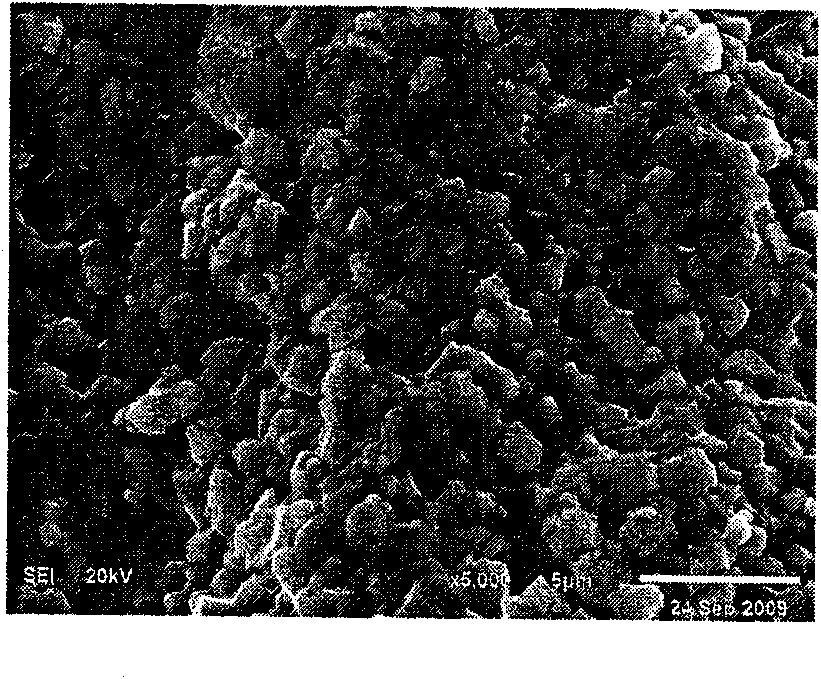

InactiveCN101660120AImprove conductivitySimple processVacuum evaporation coatingSputtering coatingTransparent electronicsMaterials science

The invention provides a multi-element doping n-type zinc-oxide-base transparent conducting film. The doping elements are unevenly distributed in the crystal grains, on the crystal grain surface and in the crystal boundary of the film. The preparation method deposits the multi-element doping zinc oxide polycrystal film by utilizing the high-vacuum magnetron sputtering technique, realizes the enriched distribution of the doping elements on the crystal grain surface and the crystal boundary by controlling the solutionization and the diffusion of various doping elements in the forming progress ofthe crystal grains and the crystal boundary, and forms the compound zinc-oxide-base film with uneven distribution of the doping elements so as to enhance the stability in the high-temperature high-humidity environment. The high-performance zinc-oxide-base transparent conducting film has the advantages of simple preparation process, superior conductivity, low cost and high transparency in visibleregions, and has wide application prospects in the fields of transparent electronics and novel photoconducting devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

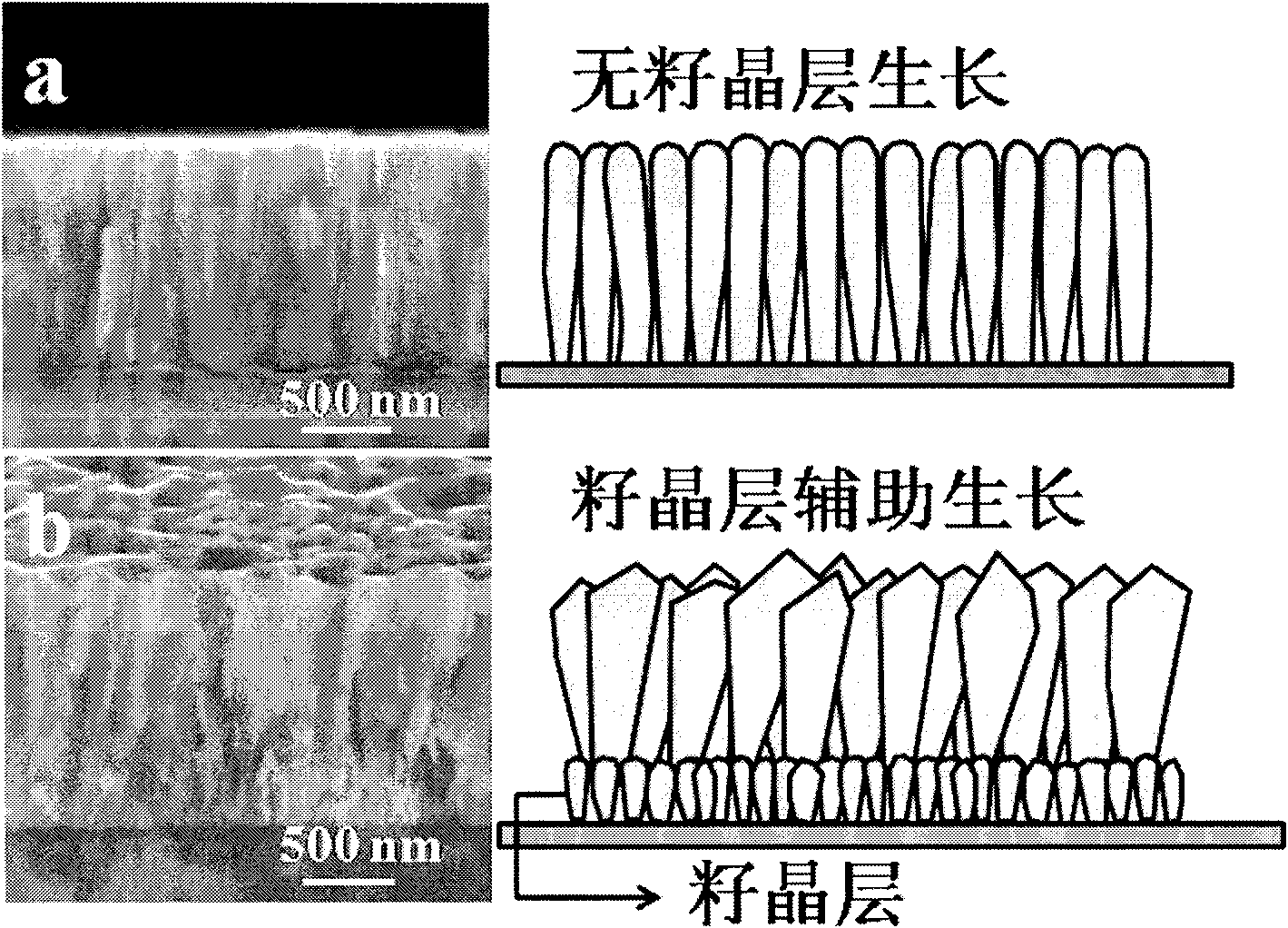

Seed crystal layer-assisting surface texturing zinc oxide transparent conductive film and preparation method thereof

ActiveCN102312192AReduce manufacturing costNo acid corrosionPolycrystalline material growthVacuum evaporation coatingRough surfaceTransparent electronics

The invention provides a seed crystal layer-assisting surface texturing zinc oxide transparent conductive film and a preparation method thereof. By means of the assistance of a zinc oxide seed crystal layer or a zinc oxide-doped seed crystal layer on a substrate, a nucleating / growing process simultaneously happening in a zinc oxide-doped film deposition process is separated into two independent stages, and then, a highly directional compact seed crystal layer and a texturing film which has a rough surface and rapidly grows by taking the seed crystal layer as an initial crystal nucleus are formed. The high-texturing surface (better optical trapping or optical capturing effect) of the zinc oxide film prepared by the invention, with unique characteristics, is far superior to similar literature reports in transparent electrical conductivity. The seed crystal layer-assisting surface texturing zinc oxide transparent conductive film prepared by the invention is simple and easy to implement, has low manufacturing cost, is suitable for mass production, can be matched with a solar cell preparation process and has a broad application prospect in the field of transparent electronics and novelphotoelectric devices.

Owner:山东中科泰阳光电科技有限公司

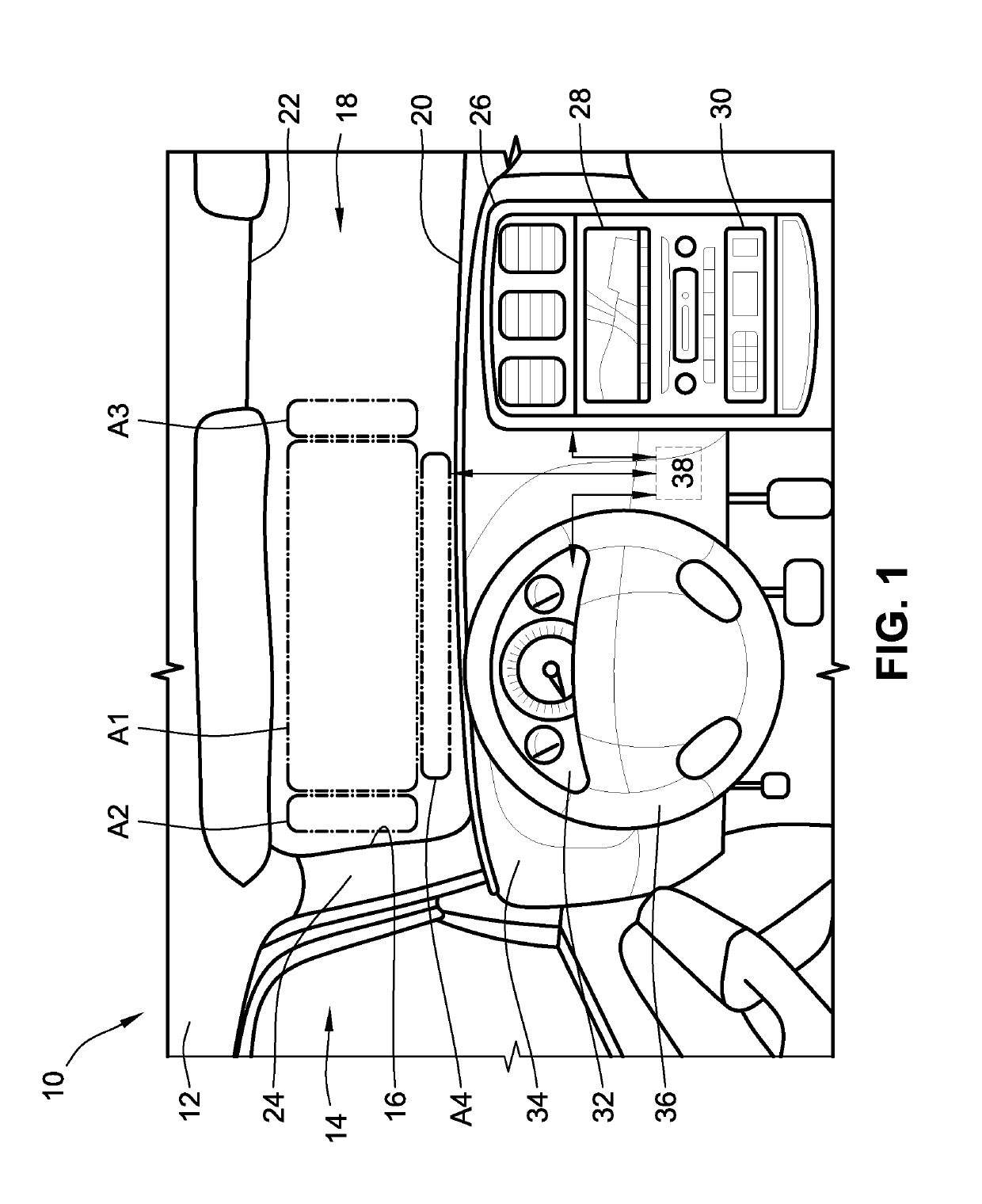

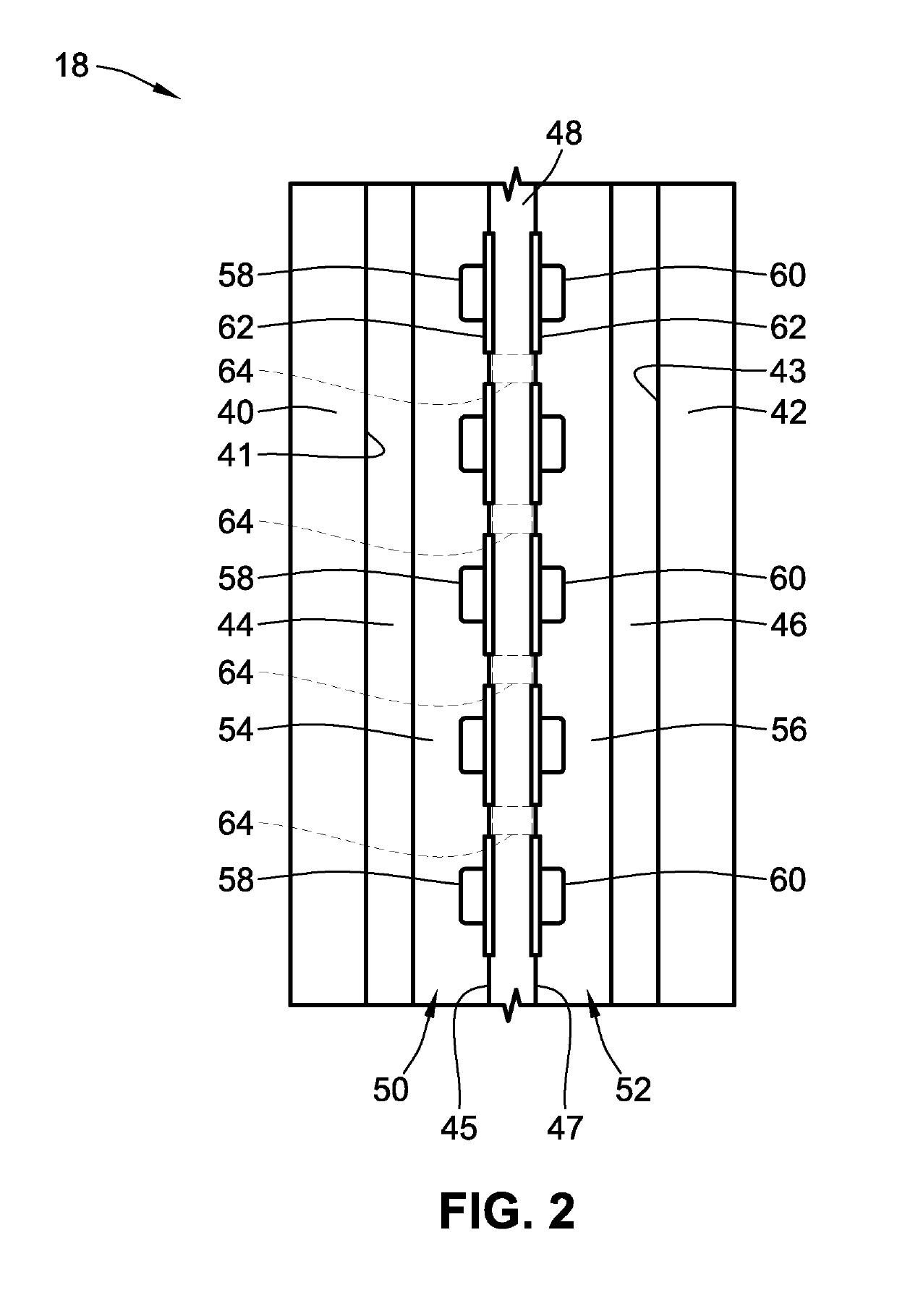

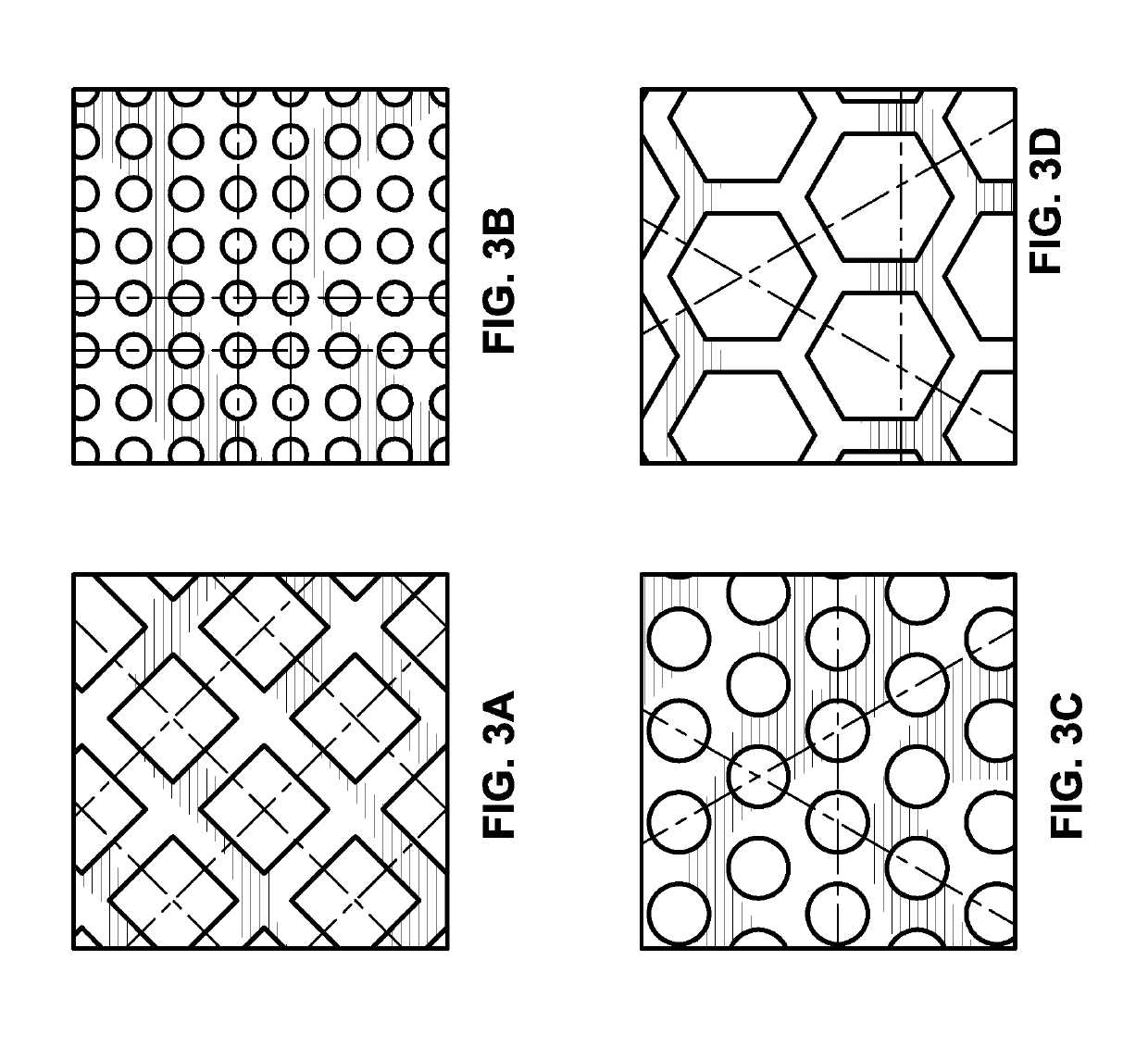

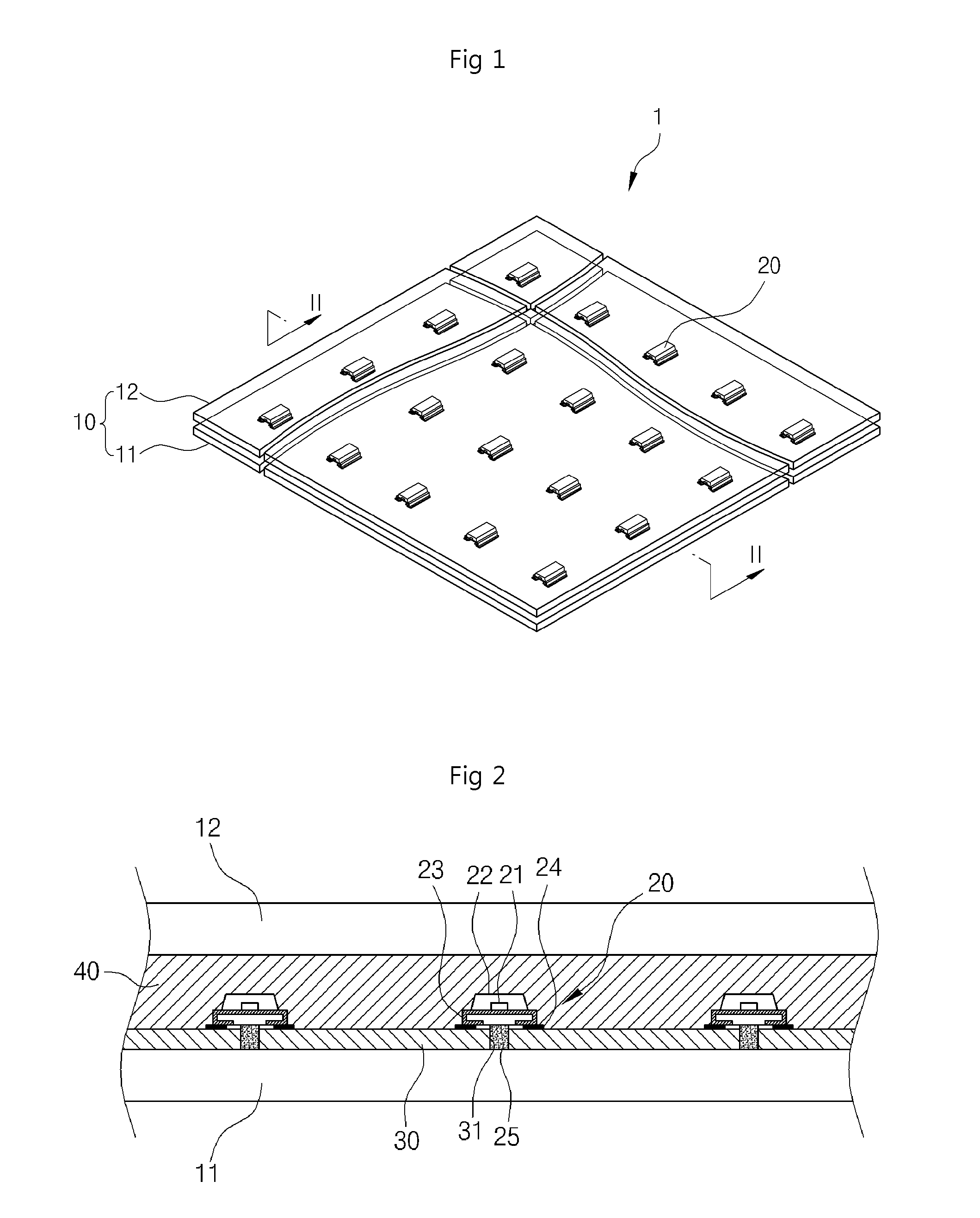

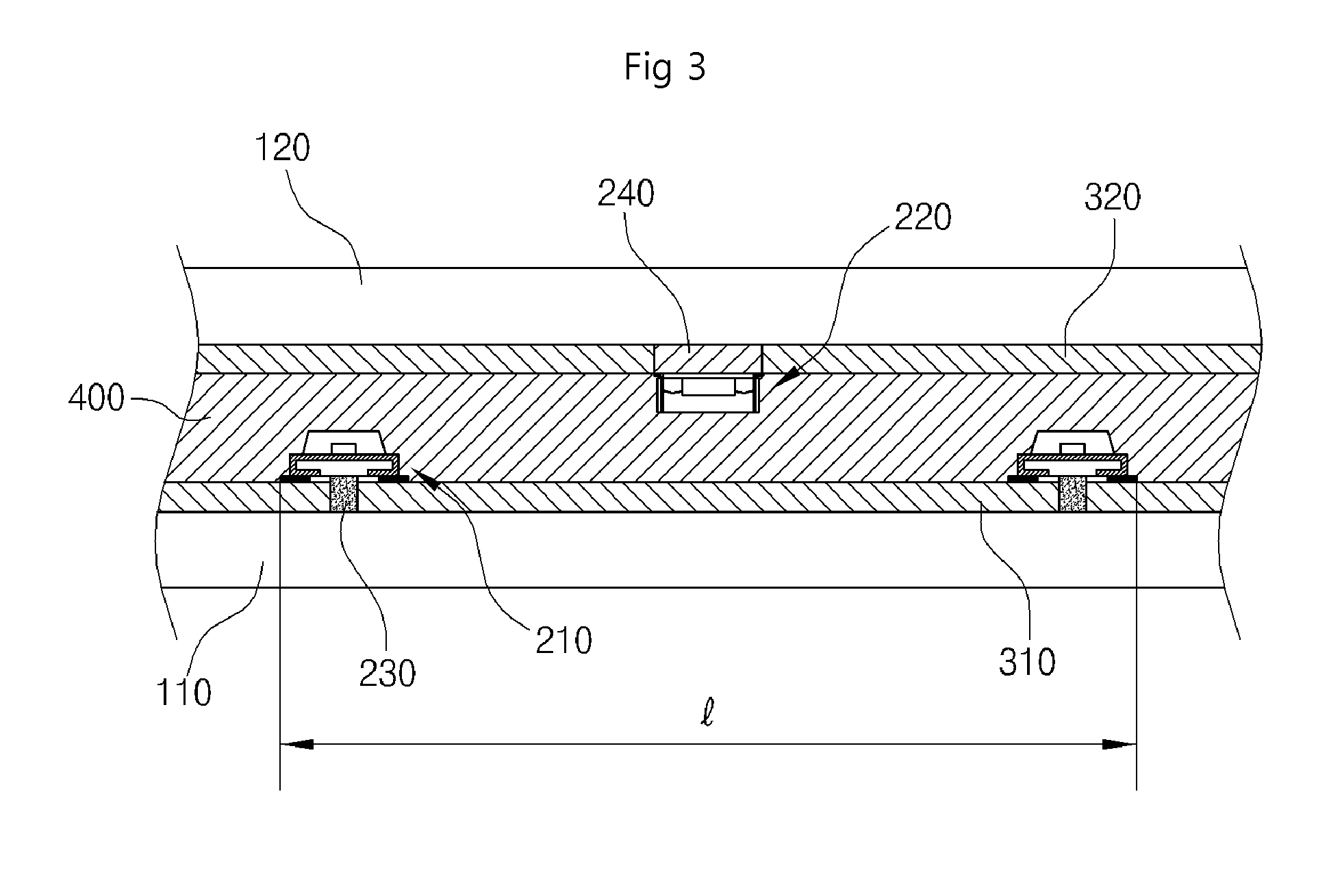

Dual-sided transparent display assemblies with non-transparent circuits

InactiveUS20190146216A1Increase awarenessReduce superfluous eye scanning and glance behaviorWindowsAntiglare equipmentTransparent electronicsSurface mounting

Disclosed are dual-sided transparent display assemblies, methods for making / using such transparent display assemblies, and motor vehicles with a window unitarily formed with a dual-sided, laminated-glass transparent display unit. A representative dual-sided transparent electronic display device includes first and second rigid transparent layers juxtaposed in opposing, spaced face-to-face relation with each other. Adhesive layers are positioned on the interior surfaces of these rigid transparent layers. First and second display circuits are attached via the adhesive layers to the first and second rigid transparent layers, respectively. Each display circuit includes a discrete array of electronically-activated light elements. The electronic display device also includes a flexible substrate with a first surface mounting thereon the first circuit and an opposing second surface mounting thereon the second circuit. The flexible substrate is fabricated with a plurality of apertures, such as through holes and / or slots, interleaved with the first and second arrays of electronically-activated light elements.

Owner:GM GLOBAL TECH OPERATIONS LLC

Transparent electronic speaker device

ActiveUS20160316301A1Increase the effective surfaceImprove sound qualityInput/output for user-computer interactionLoudspeakersElectricityTransparent electronics

Disclosed is a transparent electronic speaker device, including a transparent speaker, a touch control panel and a display panel which are sequentially stacked. The touch control panel provides a touch control function, and the display panel possesses a display function. The transparent speaker includes an upper conductive plate, a lower conductive plate and a transparent piezoelectric film sandwiched between the upper and lower conductive plates. The display panel generates and transfers a voltage driving signal through an electrical connection to the upper and lower conductive plates for actuating the transparent piezoelectric film to perform piezoelectric action, thereby generating vibration and sound. Therefore, the present invention not only integrates the functions of speaker, touch control and display, but also improves sound quality by use of the transparent piezoelectric film covering the whole electronic device without deteriorating display quality.

Owner:IBASE TECH

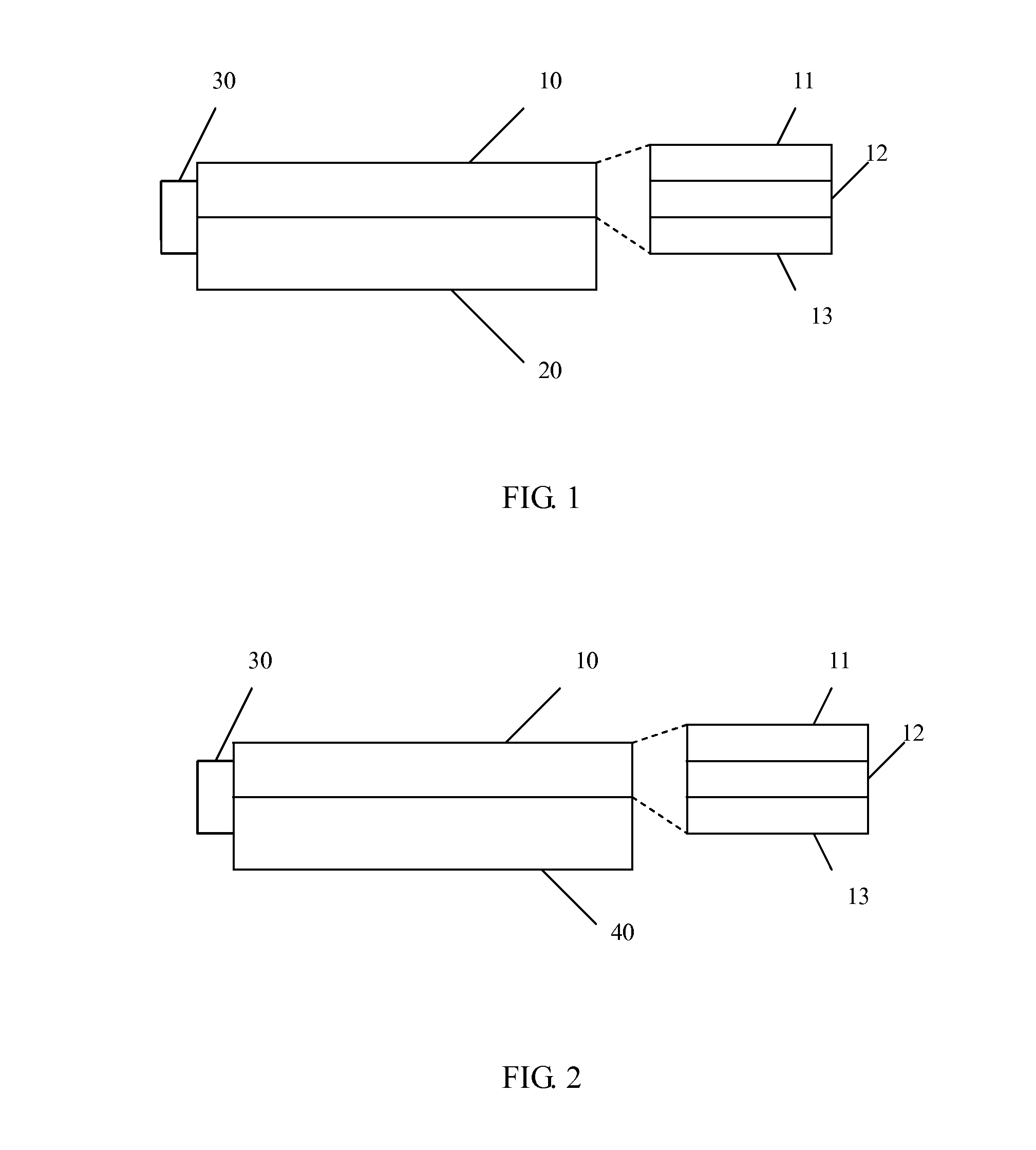

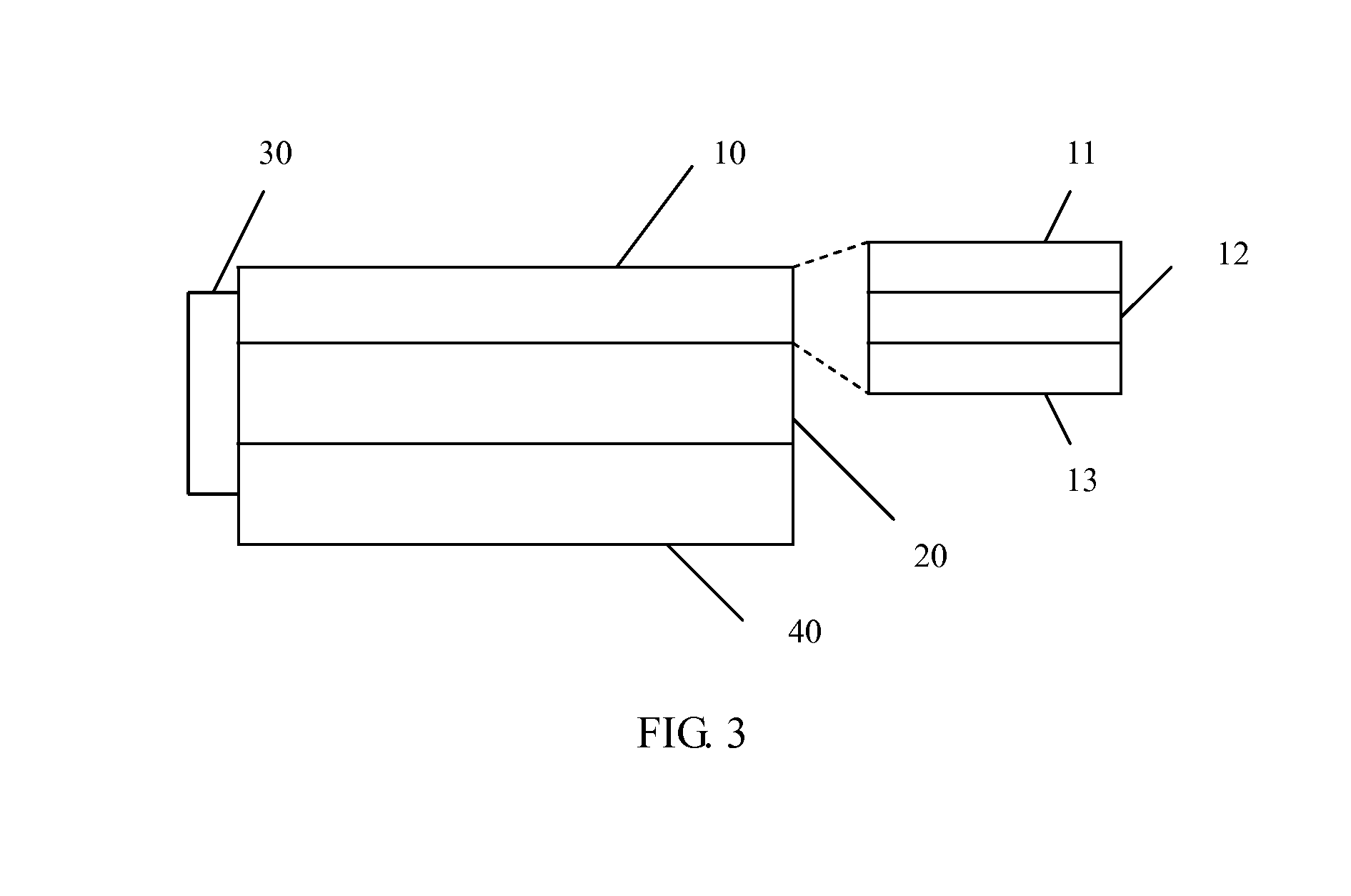

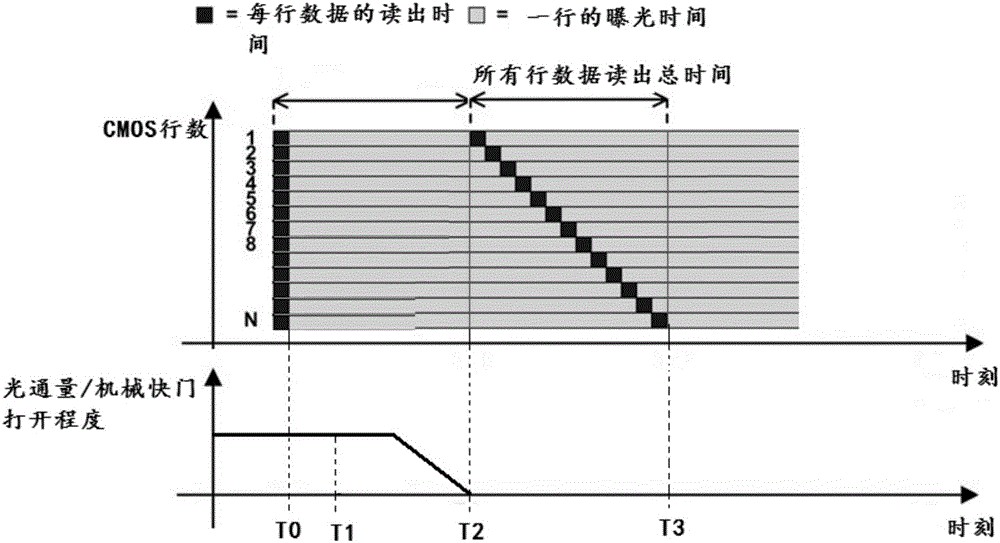

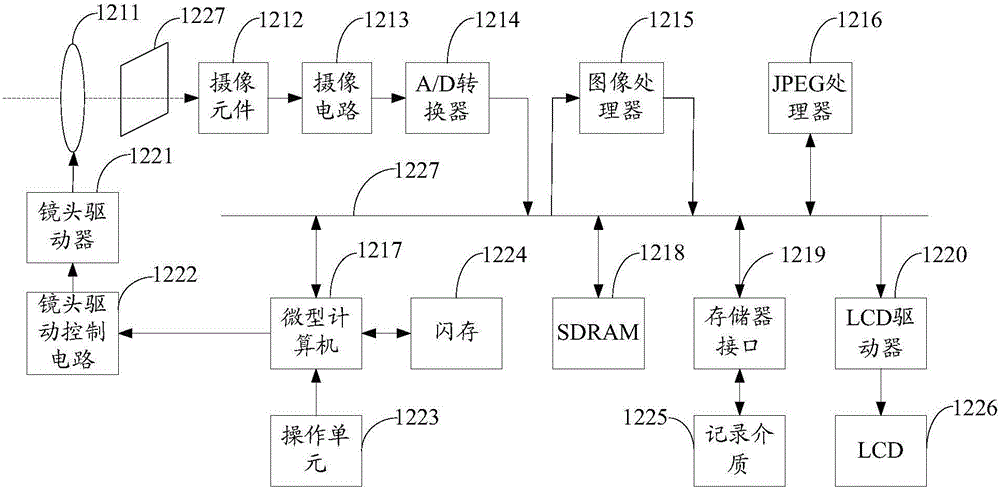

Mobile terminal and exposing method and apparatus for the same

InactiveCN105915812AExtended service lifeNo exposure unevennessTelevision system detailsColor television detailsElectricityCMOS

The invention discloses a mobile terminal which comprises a CMOS image sensor with an electronic black card on its light entrance side. The transparent electronic black card is in a transparent state during a power-off state so as to make light enter the CMOS image sensor through the electronic black card. The electronic black card is in a non-light-transmitting state during a power-on state so as to block the light into the CMOS image sensor. The invention further provides an exposing method and an apparatus for the mobile terminal. With the mobile terminal, for global exposure, all that needs to be done is make the electronic black card in a power-off state, and after that, make the electronic black card in a power-on state so as to access data on pixels after exposure. As the power-up process is very fast, the switching time is negligible, causing no uneven exposures from delays. At the same time through the power-off and power-on control over the electronic black card, limited effect is caused to the electronic black card, making it possible to have a longer service life than through the use of a mechanical shutter.

Owner:NUBIA TECHNOLOGY CO LTD

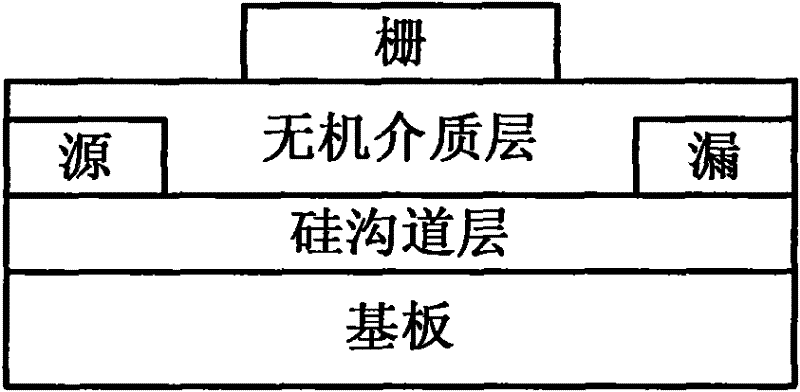

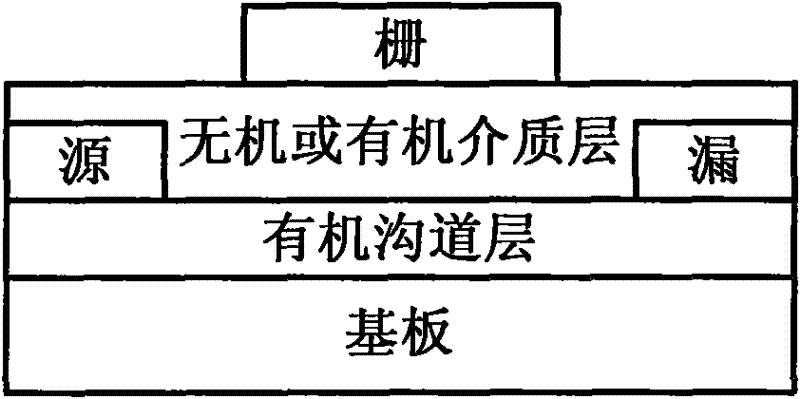

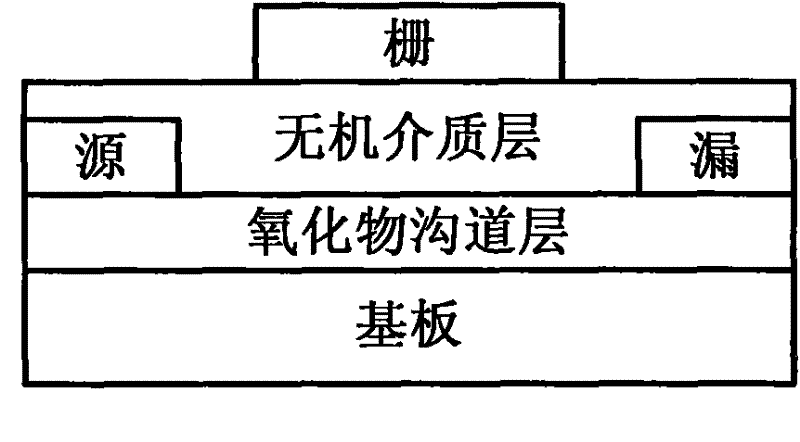

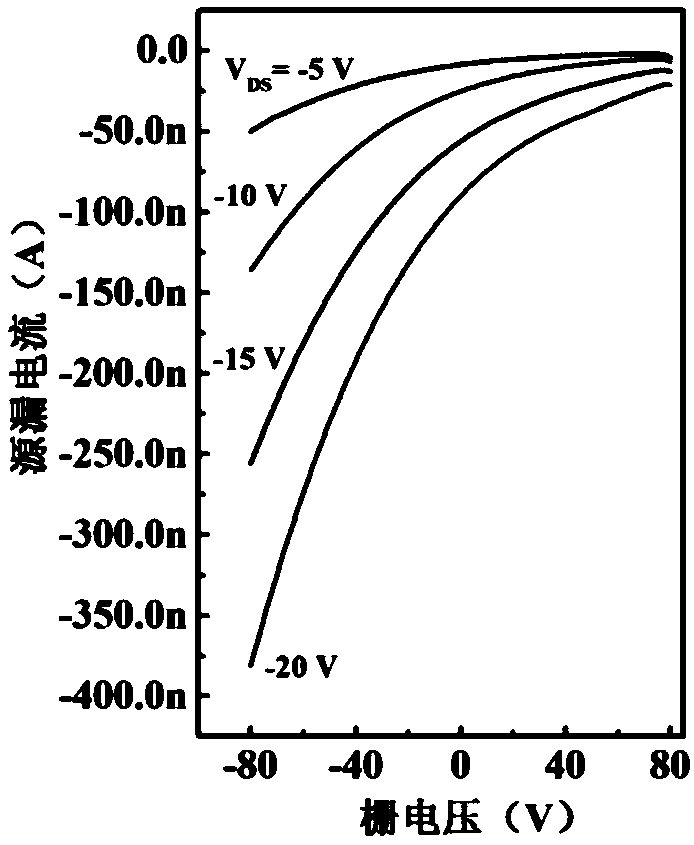

Mixed structure thin-film transistor taking oxide semiconductor as channel layer

InactiveCN102222698AGood electrical propertiesImprove transmittanceTransistorTransparent electronicsCharge carrier mobility

The invention belongs to the technical field of thin-film transistors, and relates to a mixed structure thin-film transistor taking an oxide semiconductor as a channel layer. In the transistor, the mixed structure thin-film transistor structure is formed by taking an oxide semiconductor film as a channel layer, an organic dielectric film is taken as a gate medium layer, and transparent conductive oxide films are taken as a gate electrode, a source electrode and a drain electrode. In the thin-film transistor, a glass or flexible substrate is taken as a substrate, a high-gap oxide semiconductor channel layer is prepared with a vacuum coating technology, an organic medium layer is prepared by a spin-coating method or dipping and drawing method, and the gate electrode, the source electrode and the drain electrode of the transparent conductive oxide films are prepared by a vacuum coating method. The mixed structure thin-film transistor prepared by the invention has the advantages of low preparation temperature, high carrier migration rate, high current on / off ratio, and the like, and has good application potential in the field of panel display, transparent electronics, and the like.

Owner:FUDAN UNIV

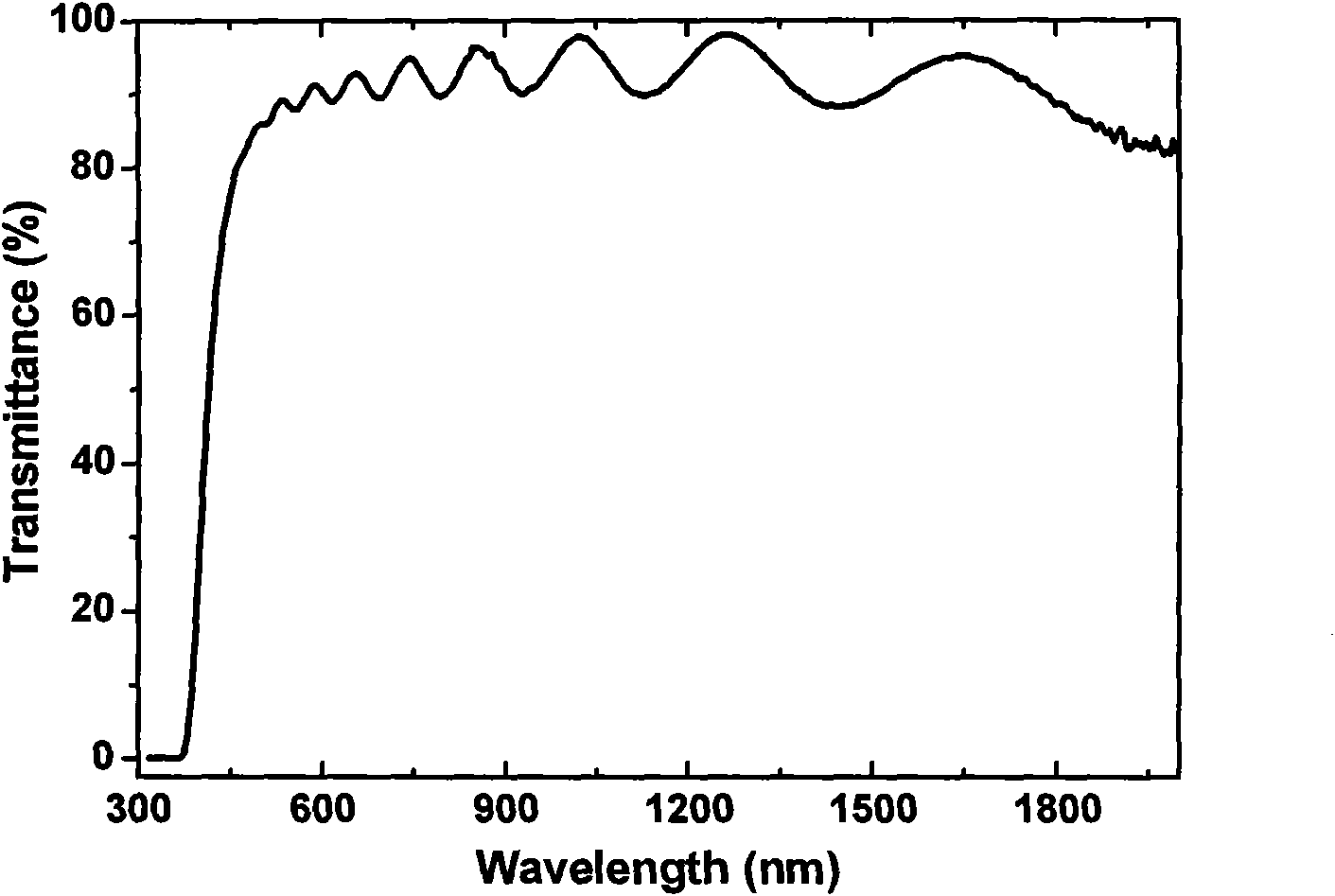

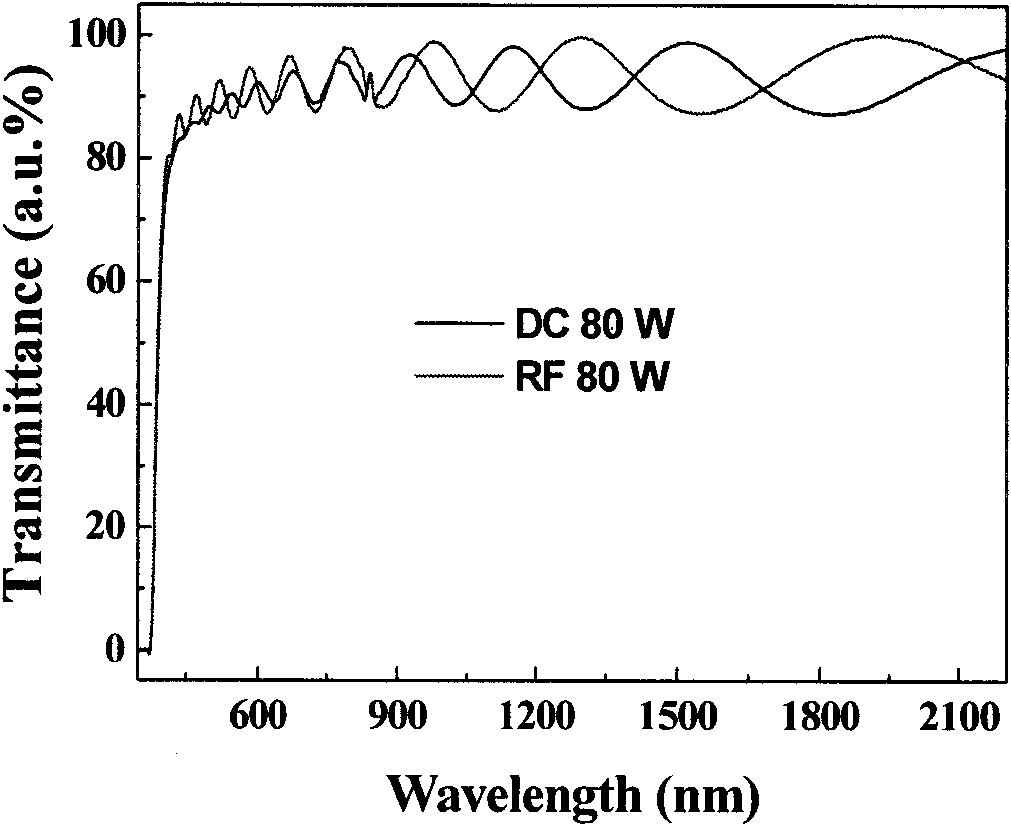

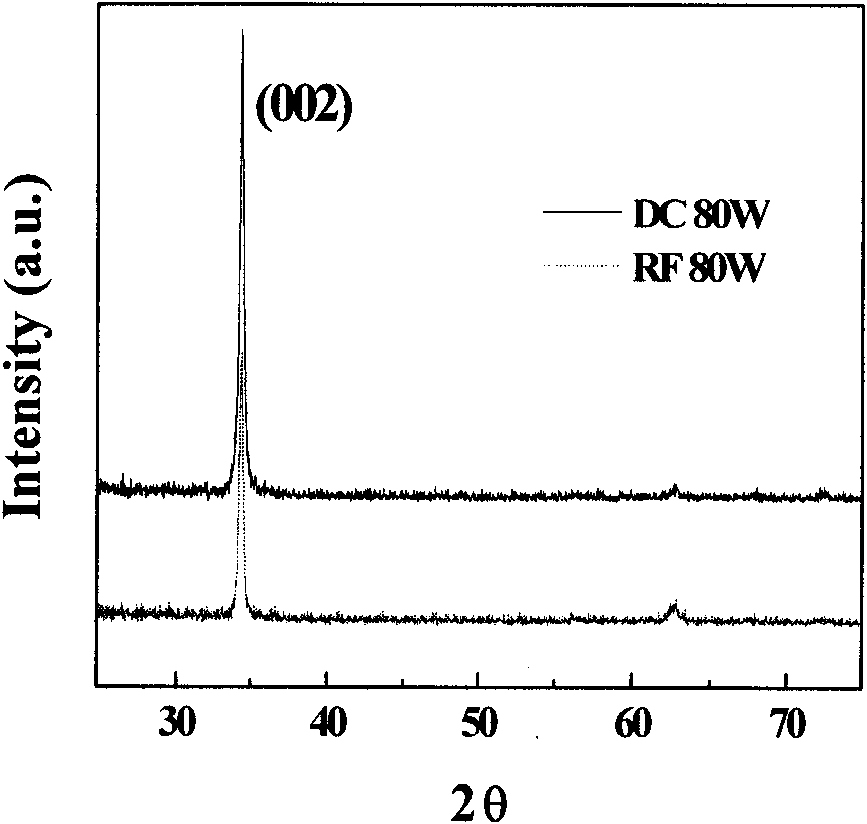

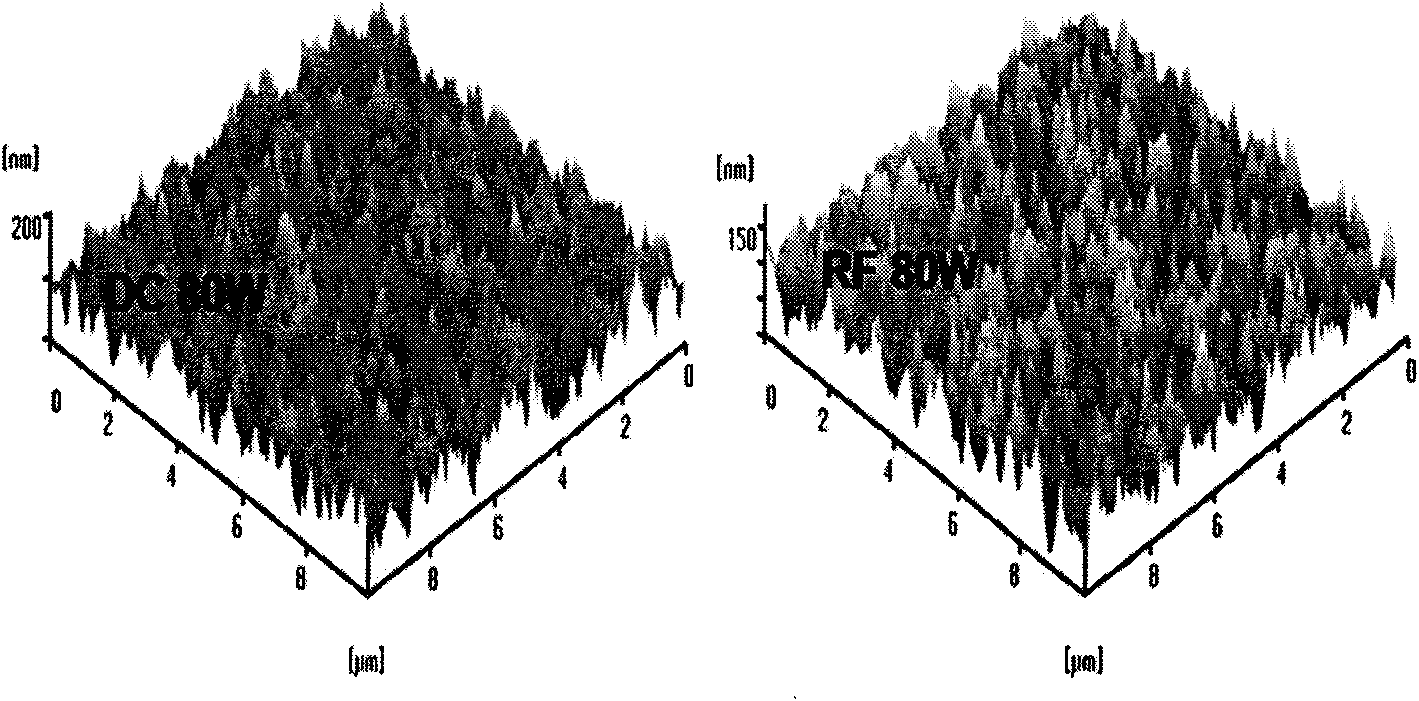

Method for preparing high-resistance transparent zinc oxide (ZnO) thin film by utilizing direct current magnetic control sputtering equipment

ActiveCN102312191AMeet application requirementsHigh densityVacuum evaporation coatingSputtering coatingHigh resistanceTransparent electronics

The invention relates to a method for preparing a high-resistance transparent zinc oxide (ZnO) thin film by utilizing direct current magnetic control sputtering equipment, which is characterized in that based on Zn-rich (or O2-inefficient) zinc oxide-based wide bandgap ceramic material target, direct current magnetic control sputtering is utilized to replace traditional radio frequency magnetic control sputtering to prepare the high-resistance ZnO-based transparent thin film, and the transparent thin film is used for the diffusion barrier layers and the window layers of thin film solar cells. Through regulating technological parameters, the resistivity of the prepared high-resistance ZnO-based transparent thin film can be controlled to be within the range of 104-108omega.cm, and the average transmissivity in visual and near infrared zones is about 90 percent. Compared with the high-resistance ZnO-based thin film prepared a radio frequency magnetic control sputtering method based on a commercial intrinsic ZnO ceramic target, under the condition of same film thickness, the transmissivity, the resistivity and the surface toughness are equivalent to those of the thin film prepared by the method of the invention. The high-resistance transparent zinc oxide (ZnO) thin film has a simple preparation process, low cost and high transparency in the visual and near infrared zones, and can be widely applied to the field of transparent electronics and novel photoelectric devices, especially the thin film solar cells.

Owner:山东中科泰阳光电科技有限公司

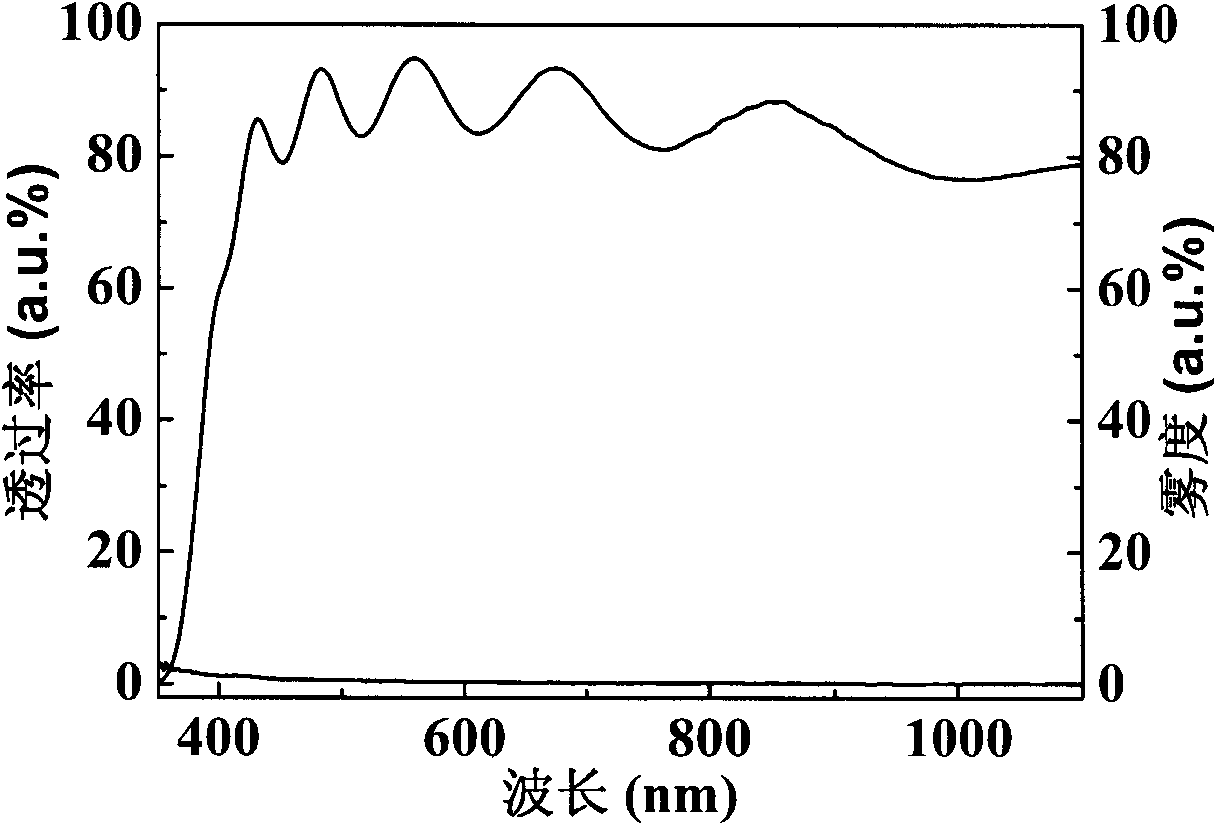

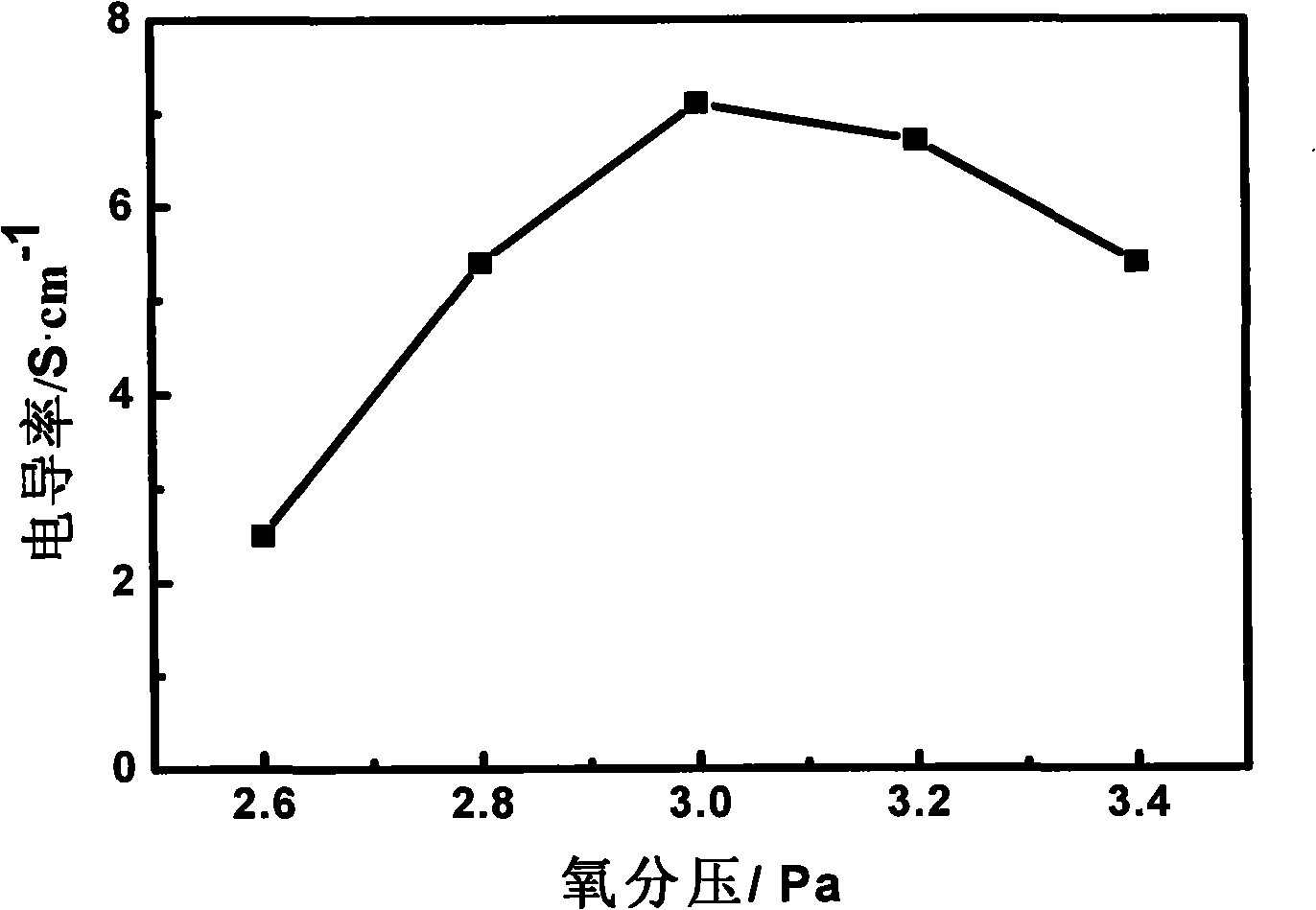

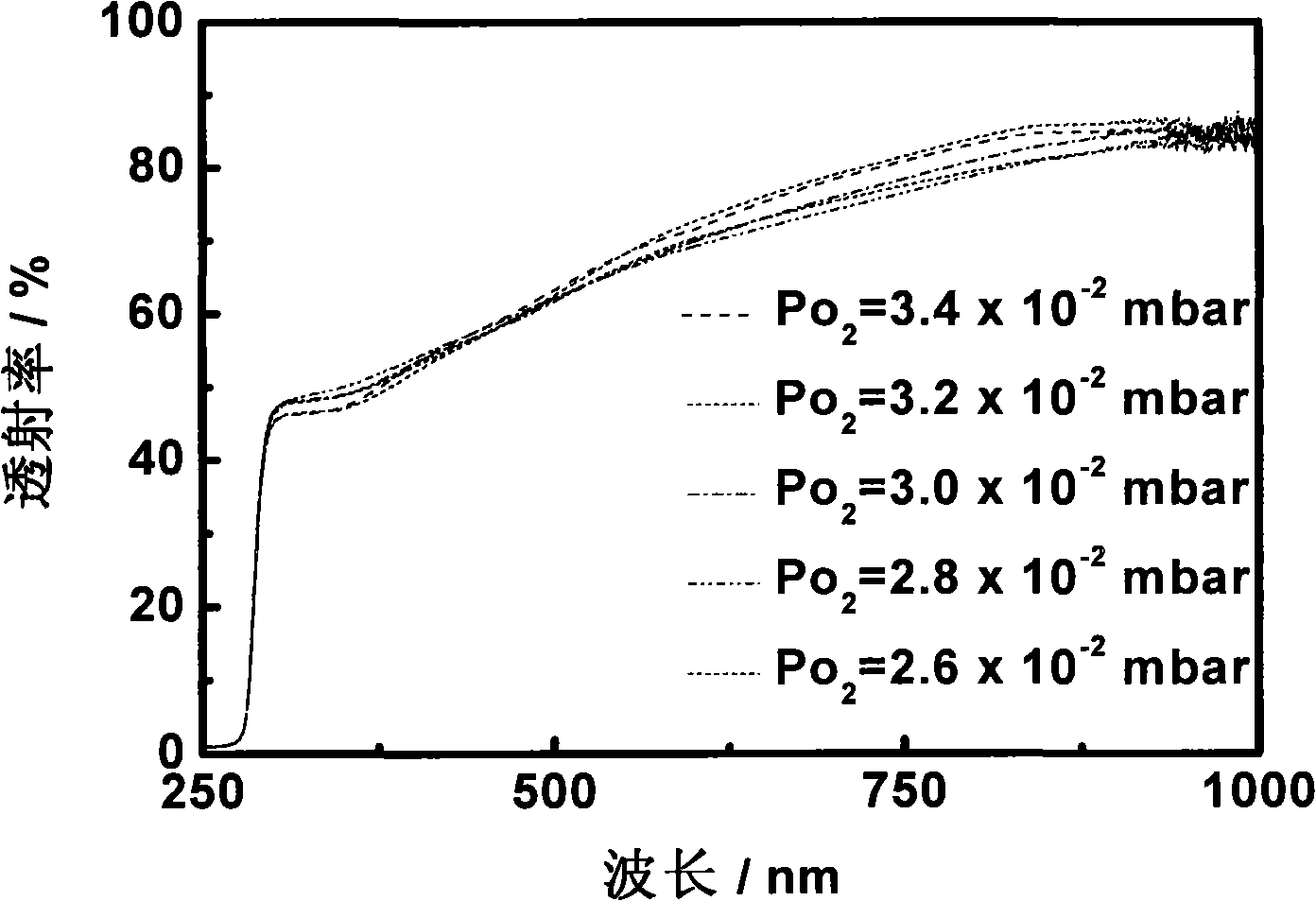

Conductive transparent copper-doped nickel oxide film and preparation method thereof

InactiveCN102110492AImprove transmittanceImprove photoelectric performanceConductive layers on insulating-supportsVacuum evaporation coatingTransparent electronicsPlasma deposition

The invention belongs to the field of transparent electronics study and in particular relates to a p-type conductive transparent copper-doped nickel oxide film and a preparation method thereof. The invention provides a p-type conductive transparent oxide semiconductor film, wherein the film is a copper-doped nickel oxide film with chemical formula being Ni1-xCuxO; and x is more than 0 and not more than 0.3. The preparation method is characterized by taking the common glass as the substrate and utilizing the Ni1-xCuxO ceramic target to prepare the film through the pulsed plasma deposition technology under the conditions of proper substrate temperature, oxygen pressure, pulse current and pulse voltage. The prepared film has such excellent photoelectric properties as high conductivity, high transmissivity in the visible light range and the like. Meanwhile, the preparation method has the advantages of simpleness and convenience in operation and relatively low equipment price. Therefore, the novel film material and the preparation method have certain application potentials in the field of semiconductor optoelectronics.

Owner:FUDAN UNIV

Zinc oxide-based wide bandgap ceramic target and preparation method thereof

ActiveCN102312202AHigh densityVacuum evaporation coatingSputtering coatingHigh resistanceTransparent electronics

The invention relates to a zinc oxide-based wide bandgap ceramic target and a preparation method thereof. The preparation method is characterized by comprising the following steps: preparing a ZnO nanometer powder with high sintering activity by adopting a liquid-phase coprecipitation method, and carrying out superhigh-compactness sintering by taking the nanometer powder as a raw material through a unique sintering process at the temperature of being not higher than 900 DEG C to obtain a high-compactness Zn-rich (or O2-inefficient) ZnO target. Based on the Zn-rich (or O2-inefficient) ZnO target, direct current magnetic control sputtering can be utilized to replace traditional radial frequency magnetic control sputtering to prepare a high-resistance ZnO-based transparent thin film, and the high-resistance ZnO-based transparent thin film can be widely applied to the field of transparent electronics and novel photoelectric devices, especially the diffusion barrier layers and the window layers of thin film solar cells. The high-performance ZnO-based ceramic target prepared by the invention has a simple preparation process, low cost, very high transmissivity and suitable resistivity, can be used as a target for preparing the high-performance high-resistance ZnO-based transparent thin film and has a broad application prospect in the field of solar cells and photoelectric devices.

Owner:山东中科泰阳光电科技有限公司

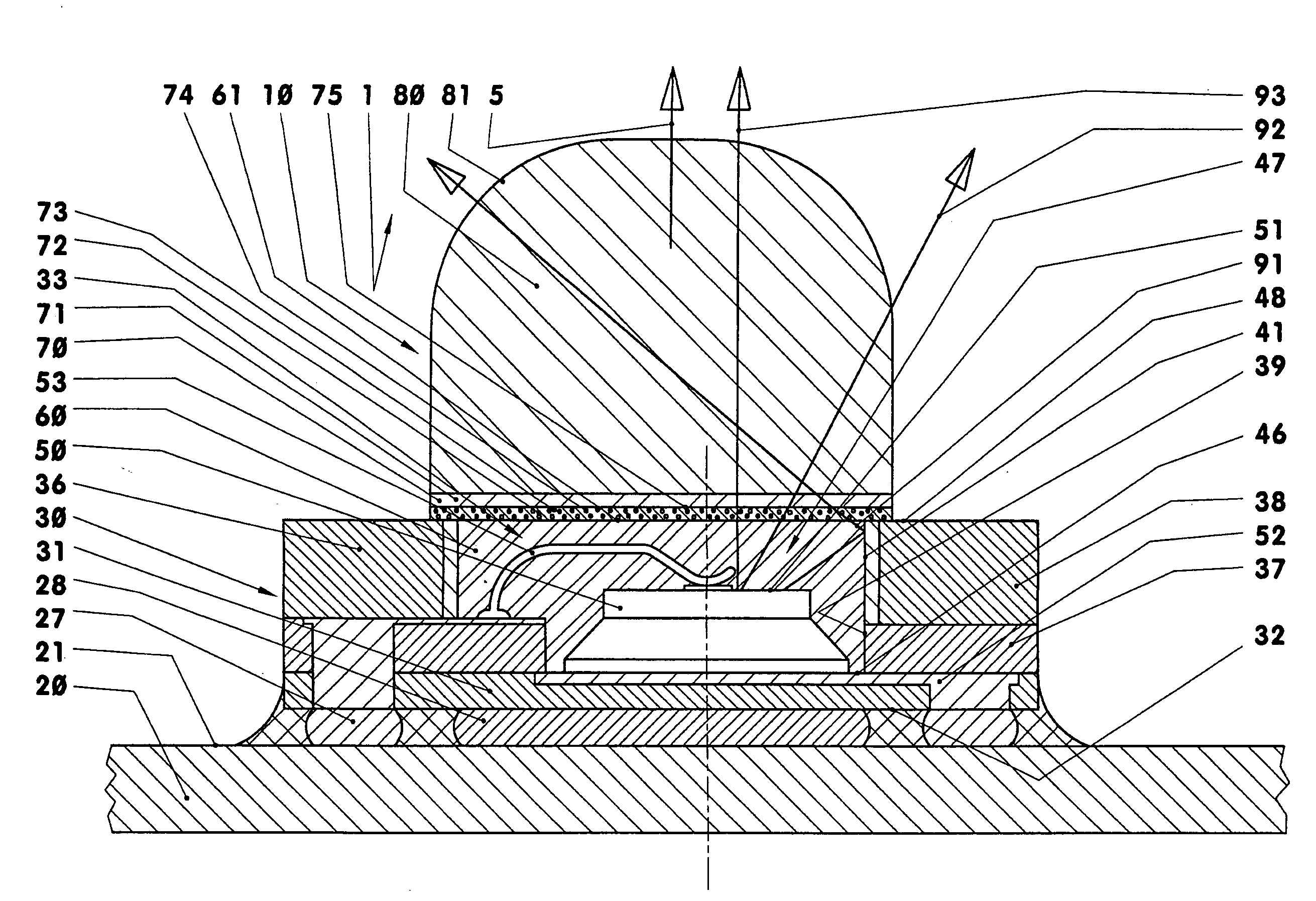

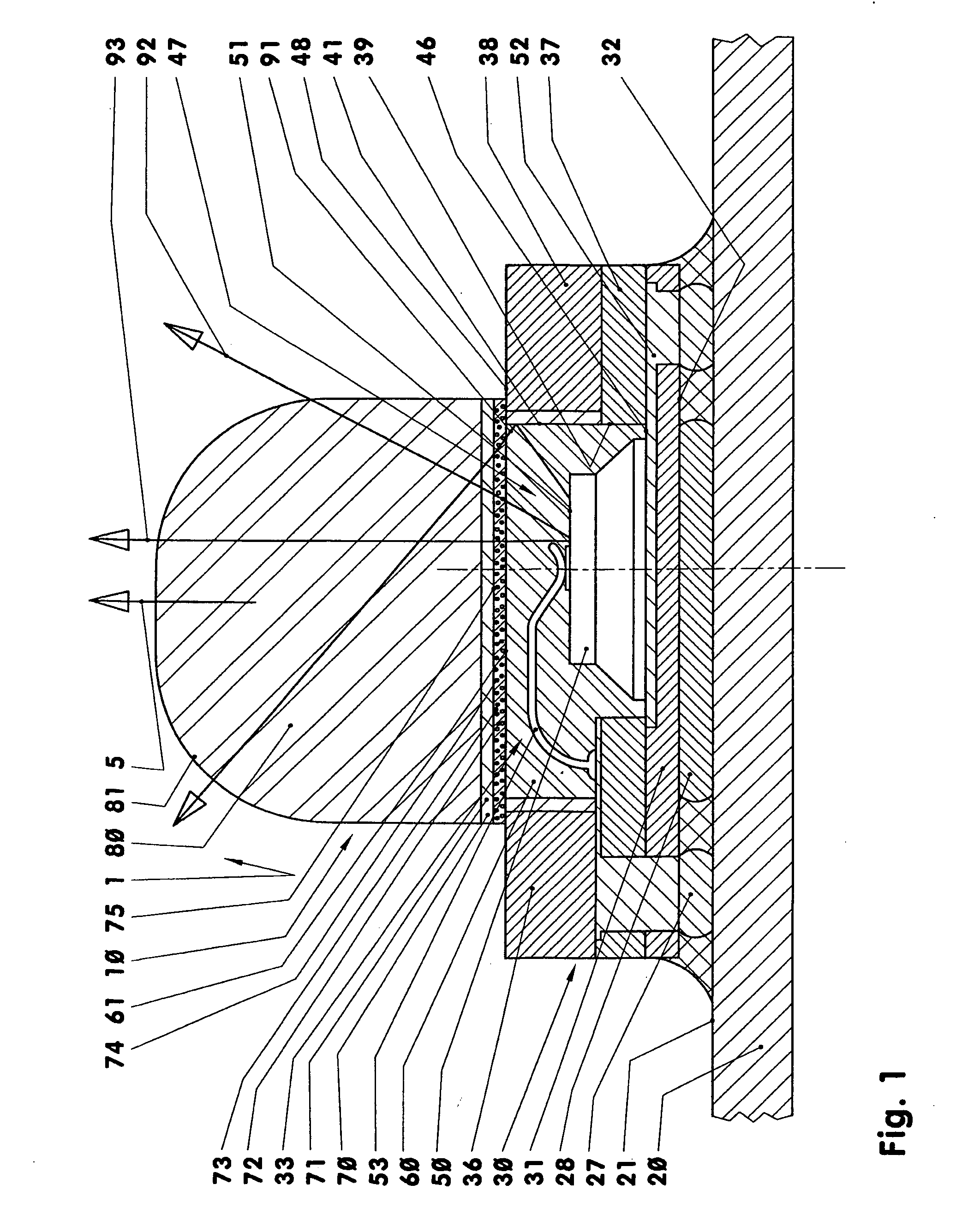

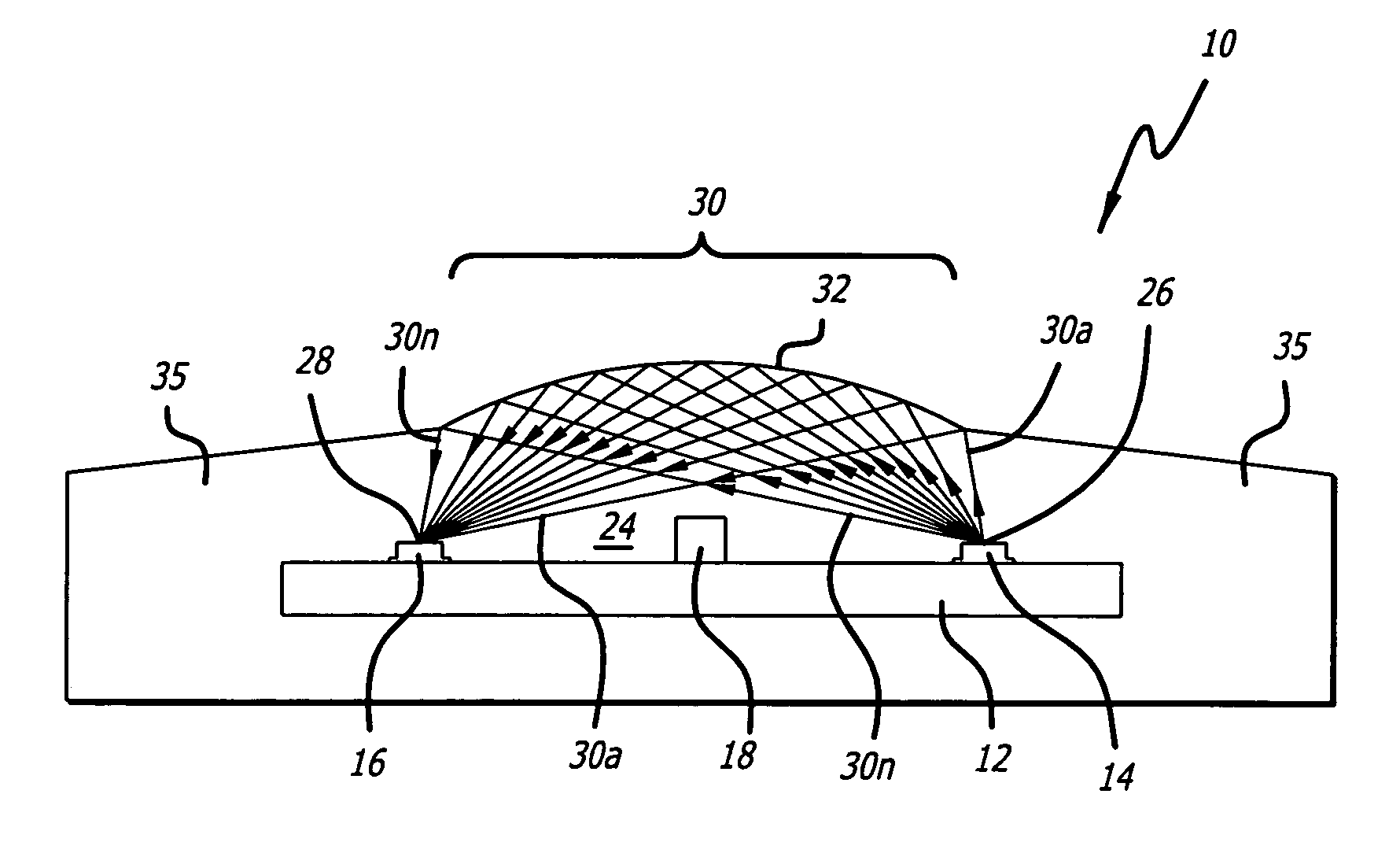

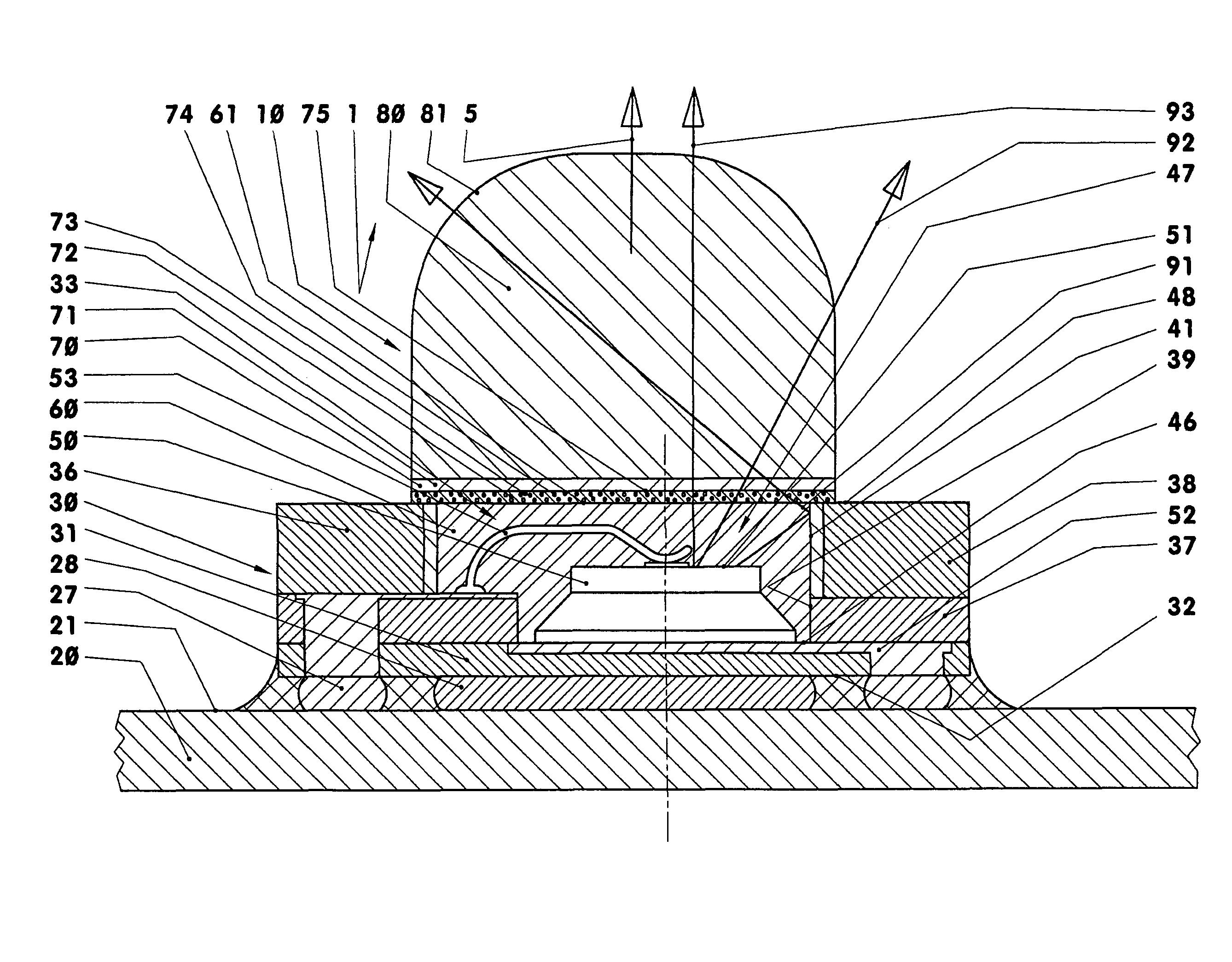

Light emitting semi-conductor diode (with high light output)

InactiveUS20080179621A1Discharge tube luminescnet screensLamp detailsTransparent electronicsRefractive index

A light-emitting semi-conductor diode comprising a light emitting chip at least partially surrounded by a transparent electronics protecting body on which a composite layer foil is disposed, the composite layer foil includes at its side facing away from the electronics protection body a carrier layer, which has a refraction index that is greater than the refraction index of the electronics protection body and, at the opposite side, an active layer of the same material of which the electronics protecting body consists.

Owner:MERCK PATENT GMBH

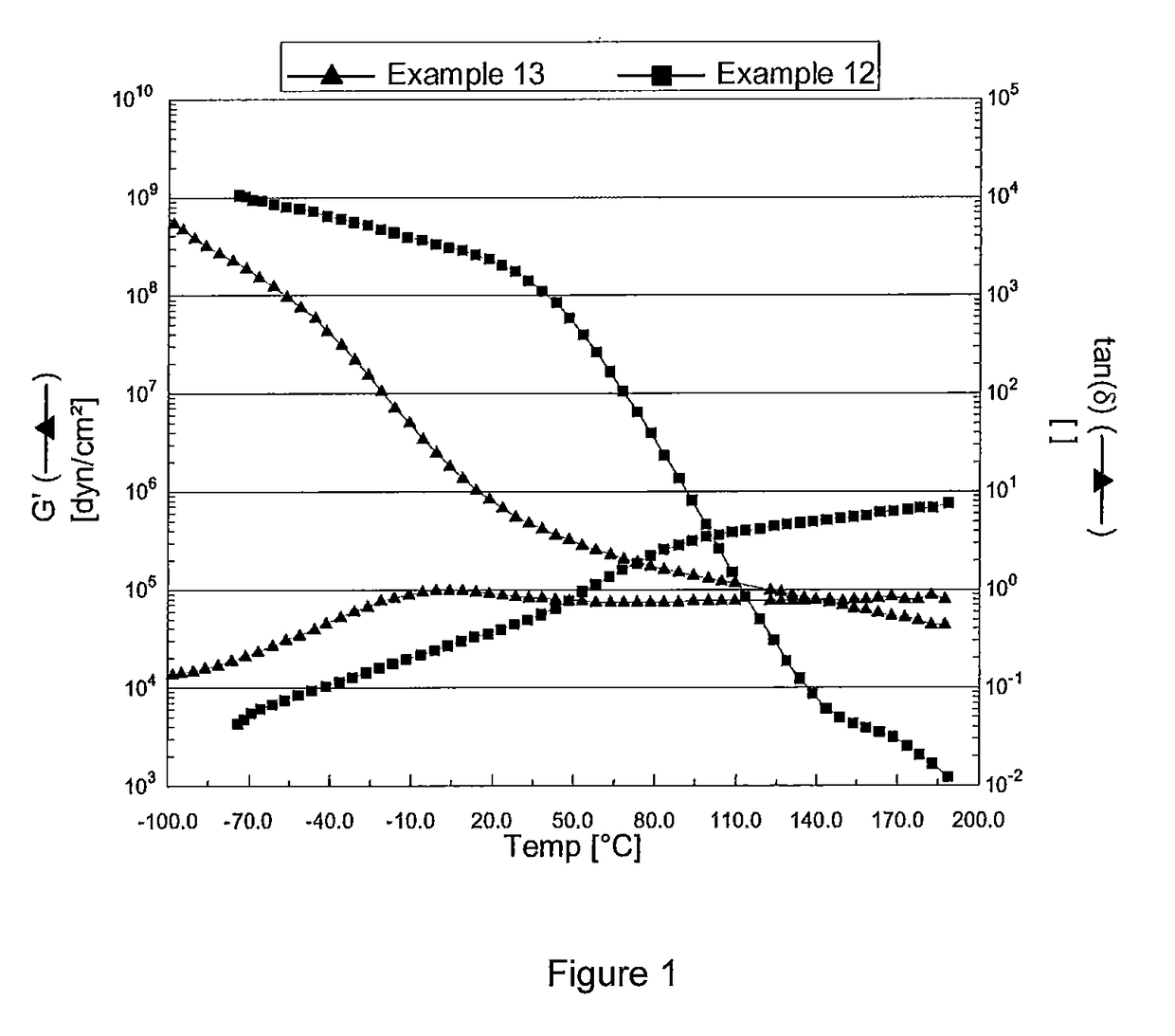

Curable and optically clear pressure sensitive adhesive and uses thereof

ActiveUS20180208799A1Good effectFacilitate transmissionAdhesive processes with adhesive heatingChemical recyclingPolymer scienceTransparent electronics

Curable silicone pressure sensitive adhesive compositions and films suitable for sealing and adhering substrates for optically clear electronic devices are described. The curable silicone pressure sensitive adhesive compositions are suitable as films or encapsulants for adhering electronic devices, e.g., LCD display, LED display, flexible display, touch screen, and flexible thin film photovoltaic module.

Owner:HENKEL KGAA

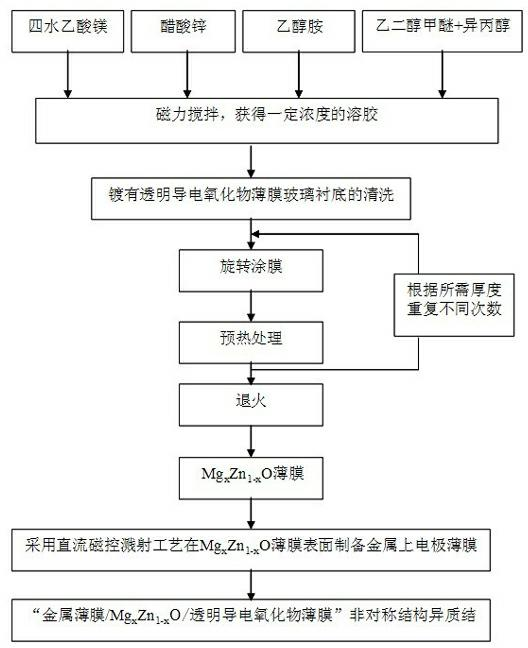

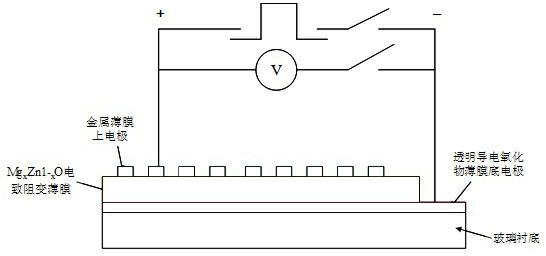

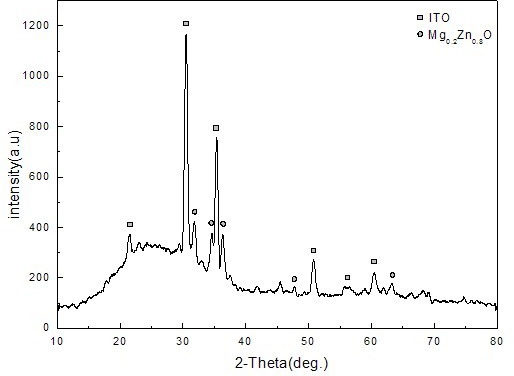

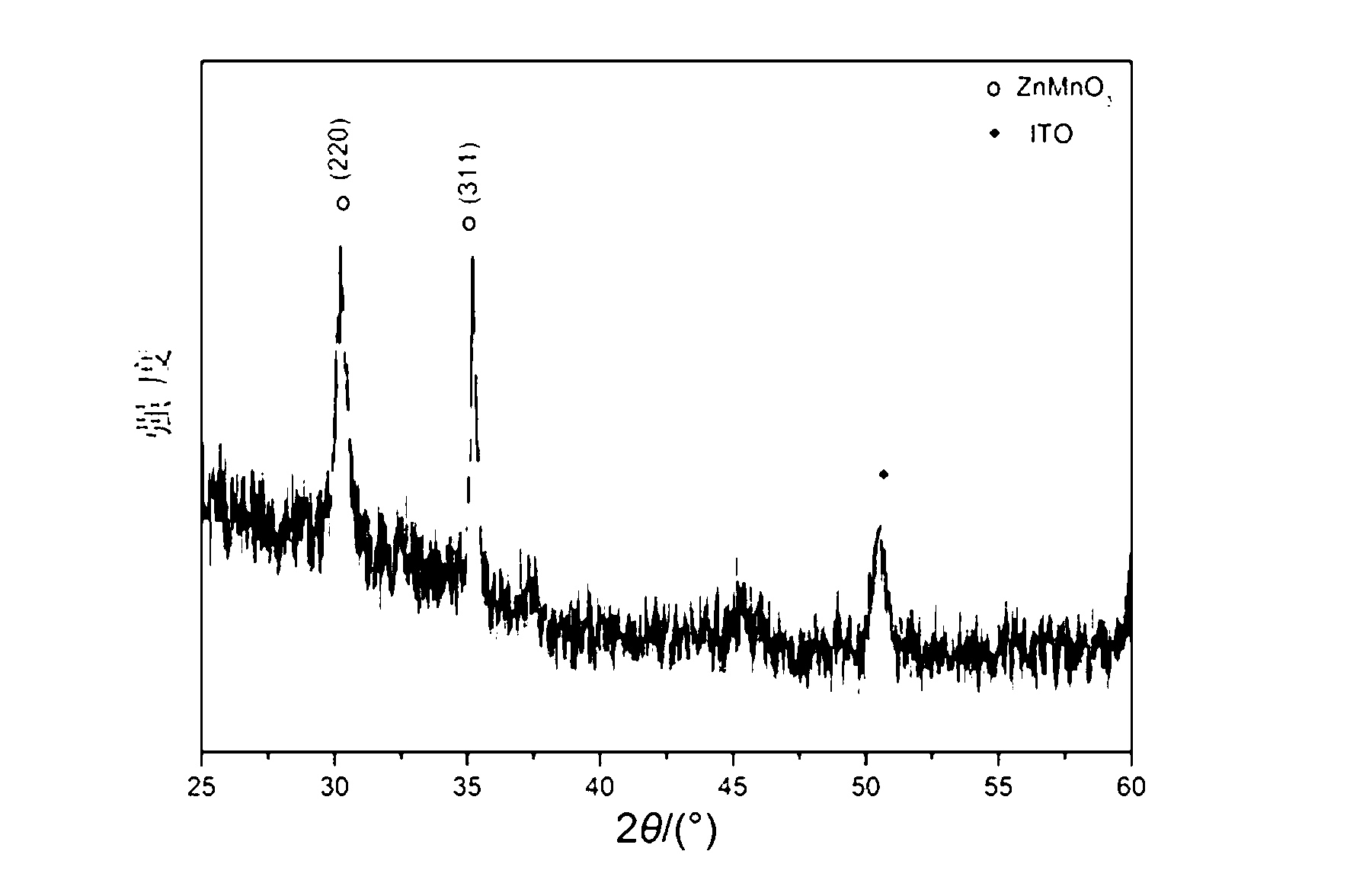

MgxZn1-xO electrically induced resistance change film and preparation method of asymmetrical structure heterojunction thereof

InactiveCN102255045AImprove fatigue resistancePrecise control of componentsElectrical apparatusHeterojunctionTransparent electronics

The invention discloses a MgxZn1-xO electrically induced resistance change film and a preparation method of an asymmetrical structure heterojunction thereof. The preparation method comprises the steps of: using glass plated with ITO (Indium Tin Oxide), AZO and other transparent conductive oxide films as a substrate; dropping prepared MgxZn1-xO sol on the substrate, carrying out spinning-coating and making a wet film, carrying out low-temperature drying treatment; carrying out preheating treatment on the dried film until a MgxZn1-xO film with required thickness is obtained; annealing the MgxZn1-xO to ensure that the film is crystallized; naturally cooling a sample to obtain the MgxZn1-xO electrically induced resistance change film; and preparing a metal top electrode film on the surface of the film by adopting a direct-current magnetron sputtering process to obtain the asymmetrical structure heterojunction of a metal film / MgxZn1-xO / transparent conductive oxide film. The invention has the advantages of capability of realizing large-area film manufacture, low cost, higher high / low resistance ratio and lower setting voltage and resetting voltage and capability of greatly improving anti-fatigue property of the electrically induced resistance change film, and can be applied to the field of transparent electronics.

Owner:GUILIN UNIV OF ELECTRONIC TECH

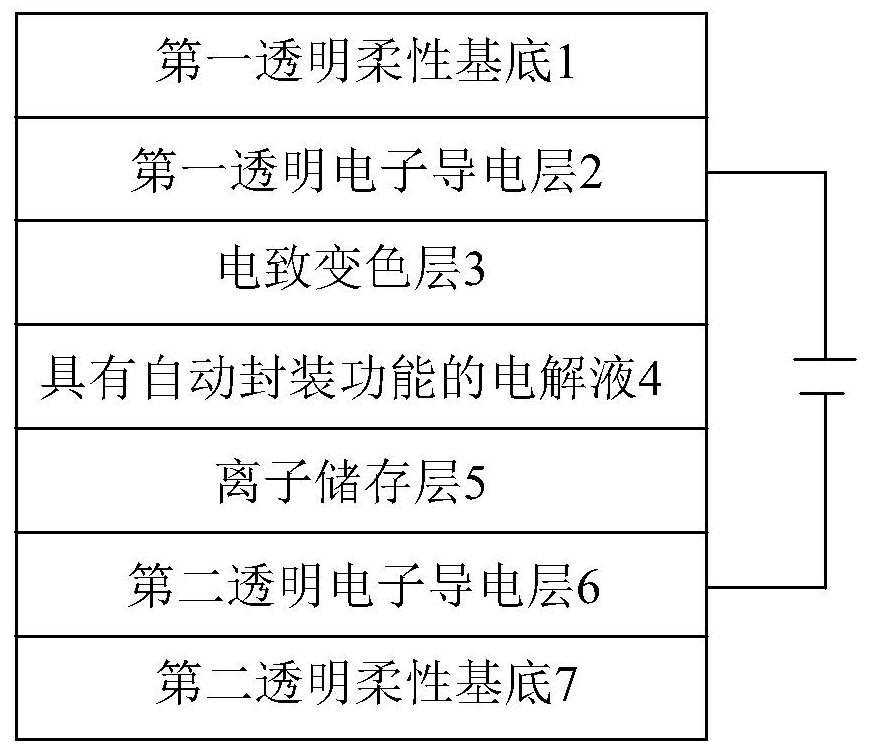

Electrochromic device capable of being cut at will and application

ActiveCN112540488AShort response timeAvoid churnNon-linear opticsSolid state electrolyteElectrolytic agent

The invention discloses an electrochromic device capable of being cut at will and application. The electrochromic device comprises a first transparent flexible substrate, a first transparent electronic conductive layer, an electrochromic layer, an electrolyte, an ion storage layer, a second transparent electronic conductive layer and a second transparent flexible substrate which are stacked in sequence, wherein the electrolyte can be automatically cured when meeting air and / or moisture so as to have an automatic packaging function. Compared with an electrochromic device prepared from solid electrolyte, the electrochromic device provided by the invention has shorter response time and better reliability, greatly reduces the risk of liquid leakage, and can be cut at will to be applied to different occasions.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Transparent memory for transparent electronic device

InactiveUS8426841B2High transparencyImprove switching characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceTransparent electronics

The present invention relates to a transparent memory for a transparent electronic device. The transparent memory includes: a lower transparent electrode layer that is sequentially formed on a transparent substrate, and a data storage region and an upper transparent layer which are made of at least one transparent resistance-variable material layer. The transparent resistance-variable material layer has switching characteristics as a result of the resistance variance caused by the application of a certain voltage between the lower and upper transparent electrode layers. An optical band gap of the transparent resistance-variable material layer is 3 eV or more, and transmittivity of the material layer for visible rays is 80% or more. The invention provides transparent and resistance-variable memory that: has very high transparency and switching characteristics depending on resistance variation at a low switching voltage, and can maintain the switching characteristics thereof after a long time elapses.

Owner:KOREA ADVANCED INST OF SCI & TECH

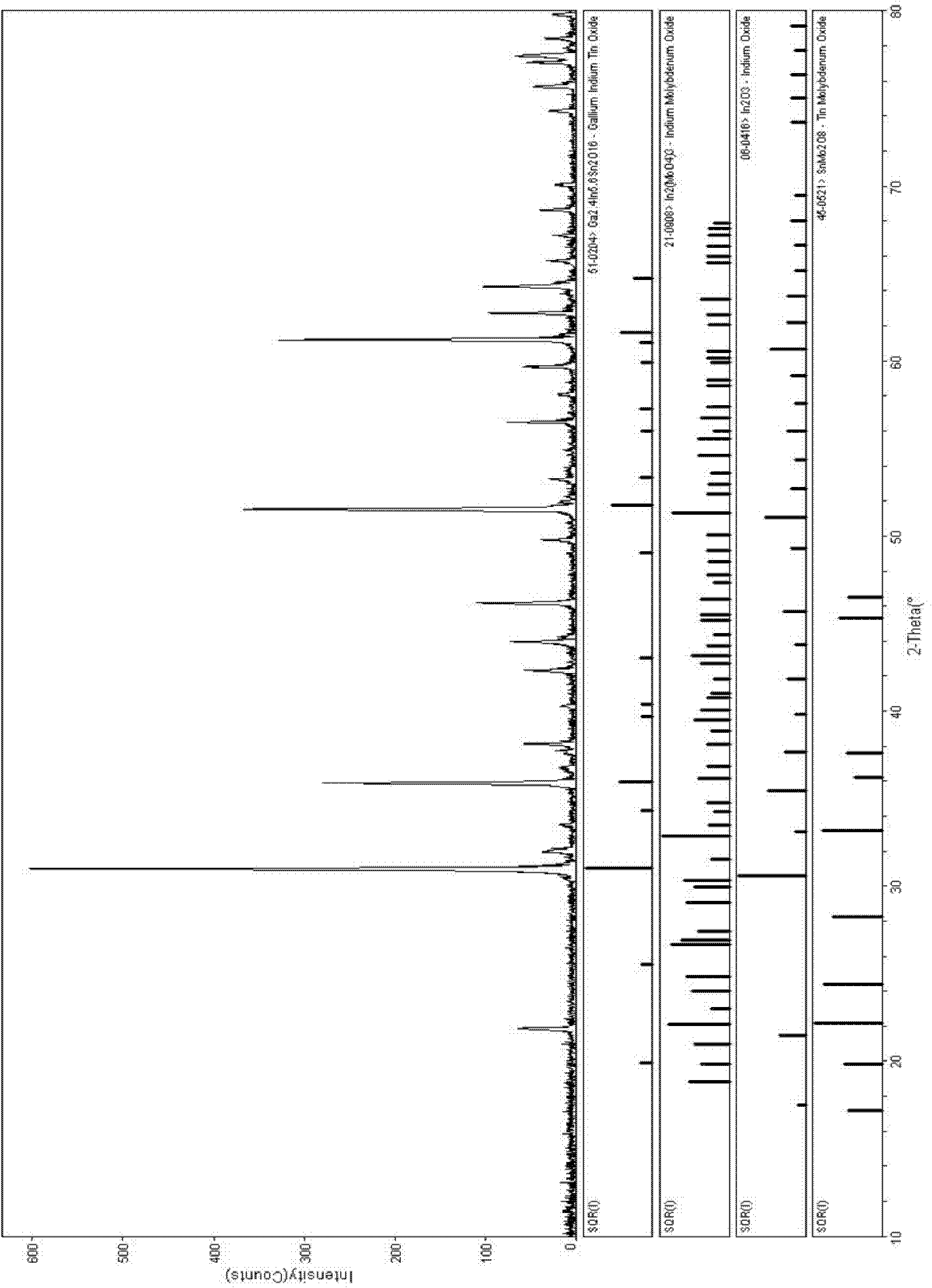

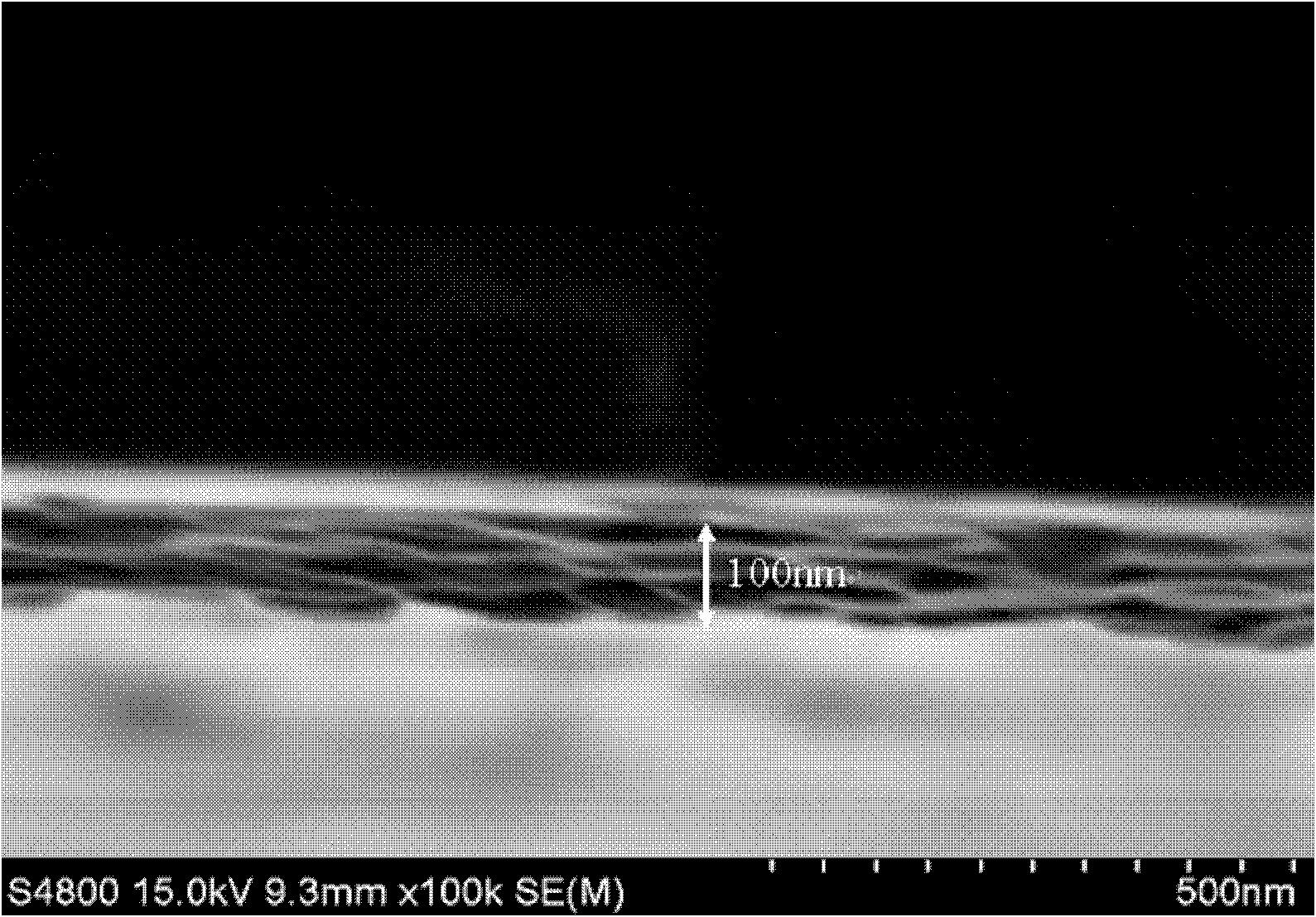

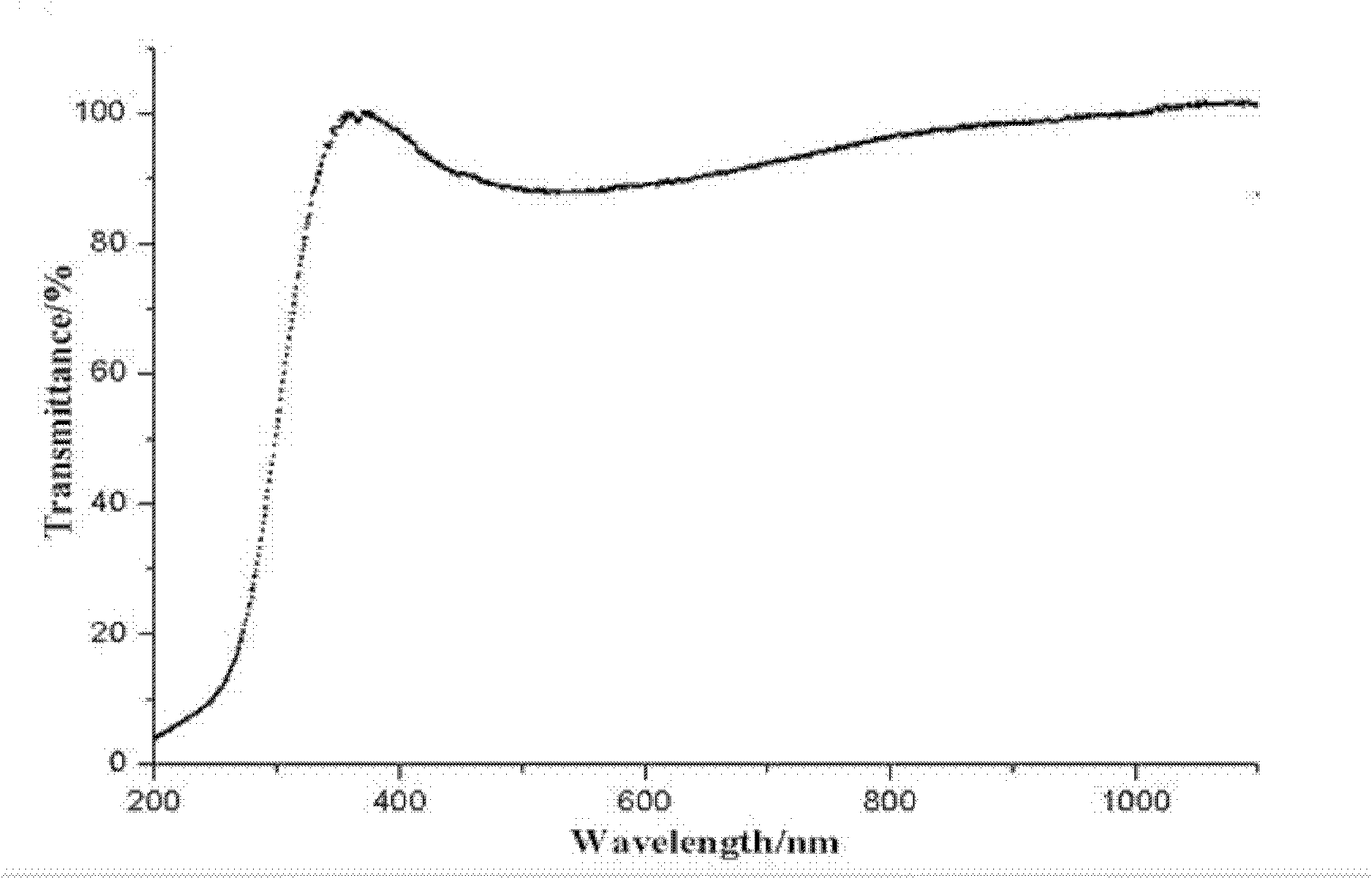

Gallium-molybdenum-codoped indium tin oxide ceramic target, gallium-molybdenum-codoped indium tin oxide transparent conductive film and preparation method

InactiveCN102181826ALow resistivitySimple preparation processVacuum evaporation coatingSputtering coatingTransparent electronicsBall mill

The invention discloses a gallium-molybdenum-codoped indium tin oxide ceramic target, a gallium-molybdenum-codoped indium tin oxide transparent conductive film and a preparation method. The gallium-molybdenum-codoped indium tin oxide (InSnGaMo) ceramic target is prepared as follows: mixing In2O3 powder, SnO2 powder, Ga2O3 powder and absolute ethyl alcohol, ball milling, pre-combining, ball milling again, pelleting, forming, sintering and annealing; and the gallium-molybdenum-codoped indium tin oxide (InSnGaMo) transparent conductive film is prepared as follows: arranging the gallium-molybdenum-codoped indium tin oxide (InSnGaMo) ceramic target in a pulse laser deposition device for deposition. In the invention, the preparation process is simple, the production is easy, the repeatability is good, and the production cost is lowered. The InSnGaMo ceramic target has the advantages of lower cost, higher relative density, and lower resistivity. The InSnGaMo transparent conductive film has a stable structure under high temperature, extremely low resistivity (less than 10-4Omega cm) and high light transmittance (more than 90%), good electrical and optical properties, and simultaneously has good weak acid corrosion property. The invention has wide application prospect in the transparent electronics field and novel photoelectric device field.

Owner:YANGZHOU UNIV

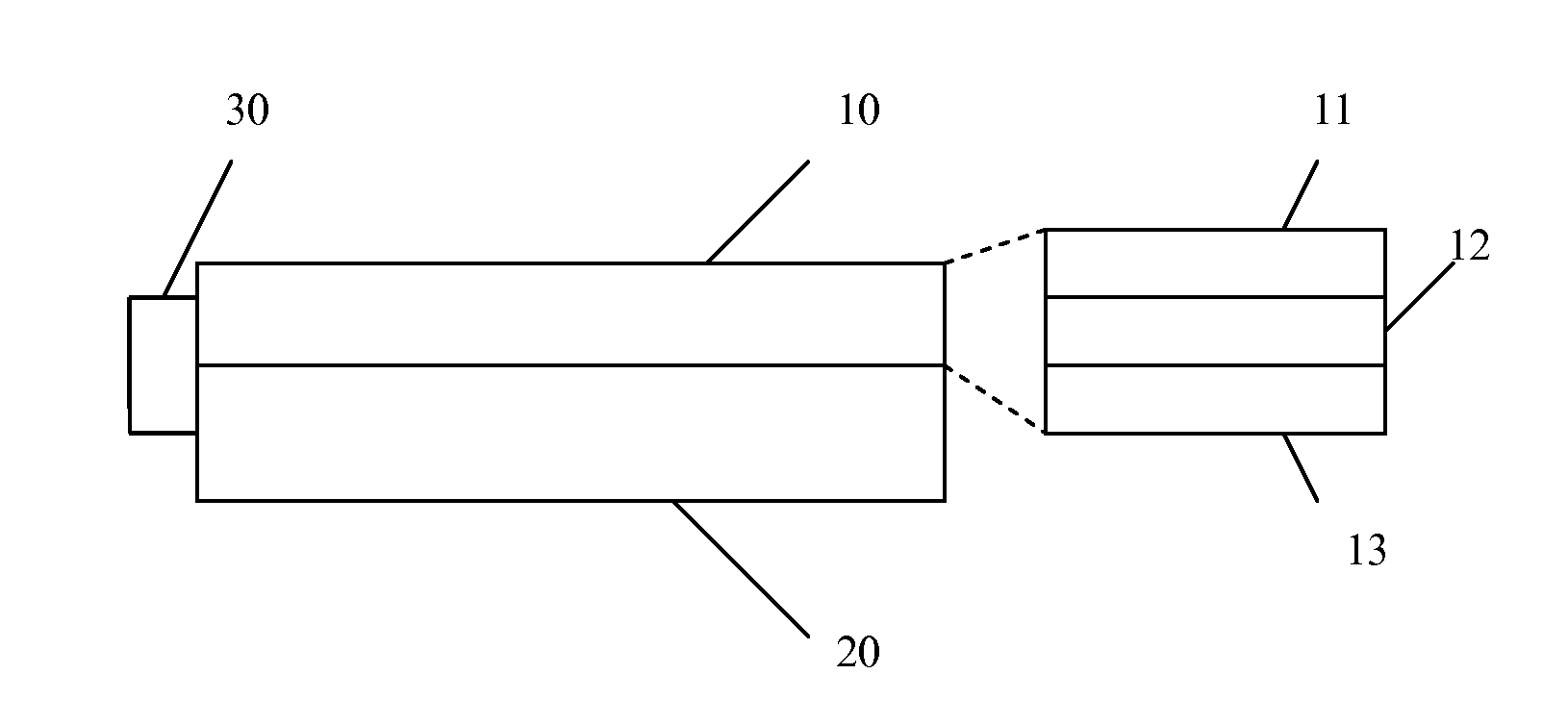

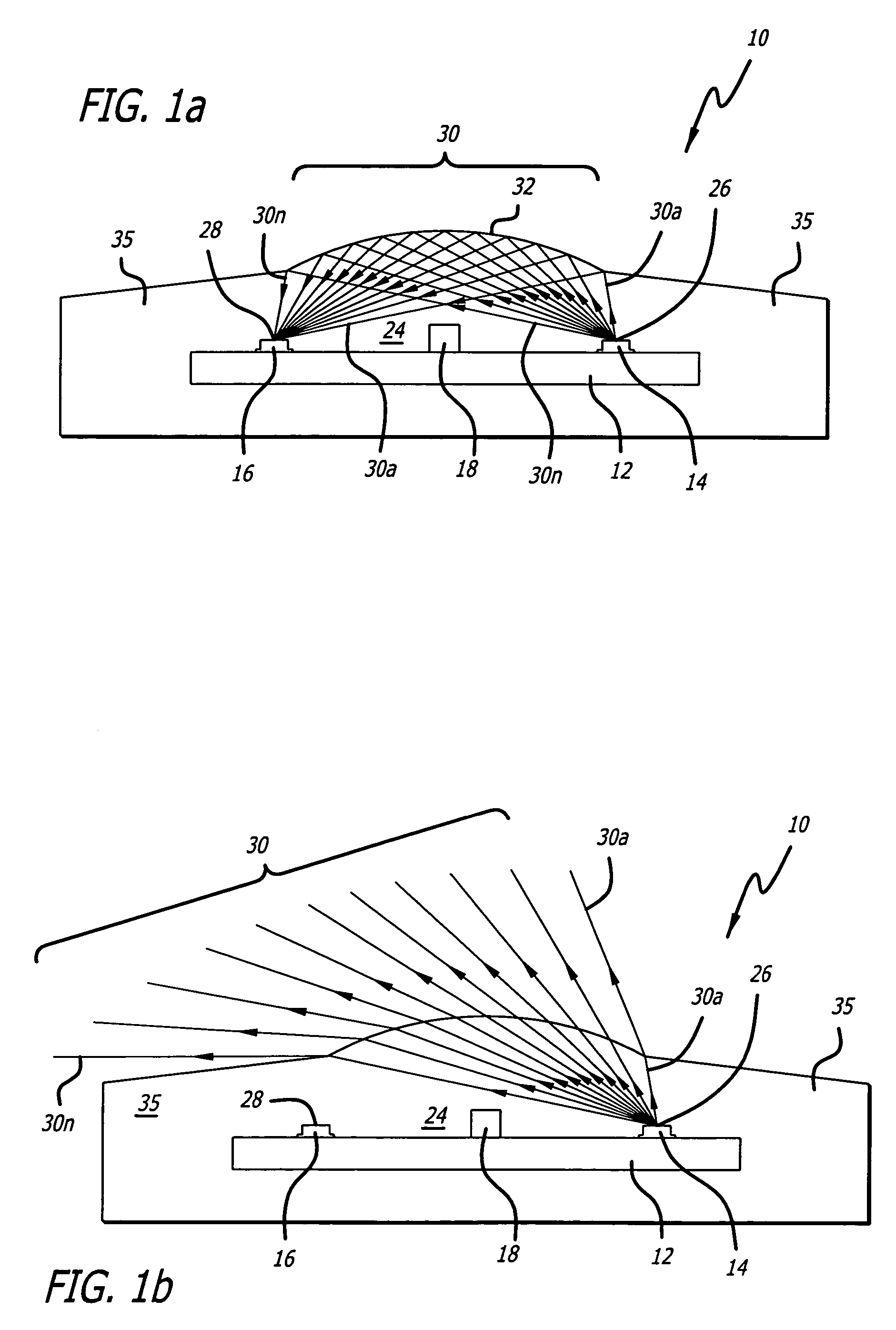

Optical moisture sensor and method of making the same

InactiveUS7247837B2Watering devicesPhase-affecting property measurementsMoisture penetrationDirect illumination

A soil moisture sensor uses a non-collimated light source and a photosensor, respectively, mounted at the foci of a transparent ellipsoidal plastic body. The dimensions of the body are such that emitted light rays are internally reflected toward the photosensor at the surface of the ellipsoid if the surface is dry, but refracted outwardly of the body when the surface is wet. The amount of light reflected onto the photosensor is thus a measure of the amount of moisture at the surface of the sensor. Direct illumination of the photosensor by the light source is prevented either by interposing opaque electronic components between them on a circuit board, or by taking advantage of light source characteristics to minimize the amount of transmitted light. If a circuit board is used, it is completely encapsulated against moisture penetration by fixing it in a carrier and molding the body around and onto the carrier to form a monolithic unit with the carrier and circuit board.

Owner:TORO CO THE

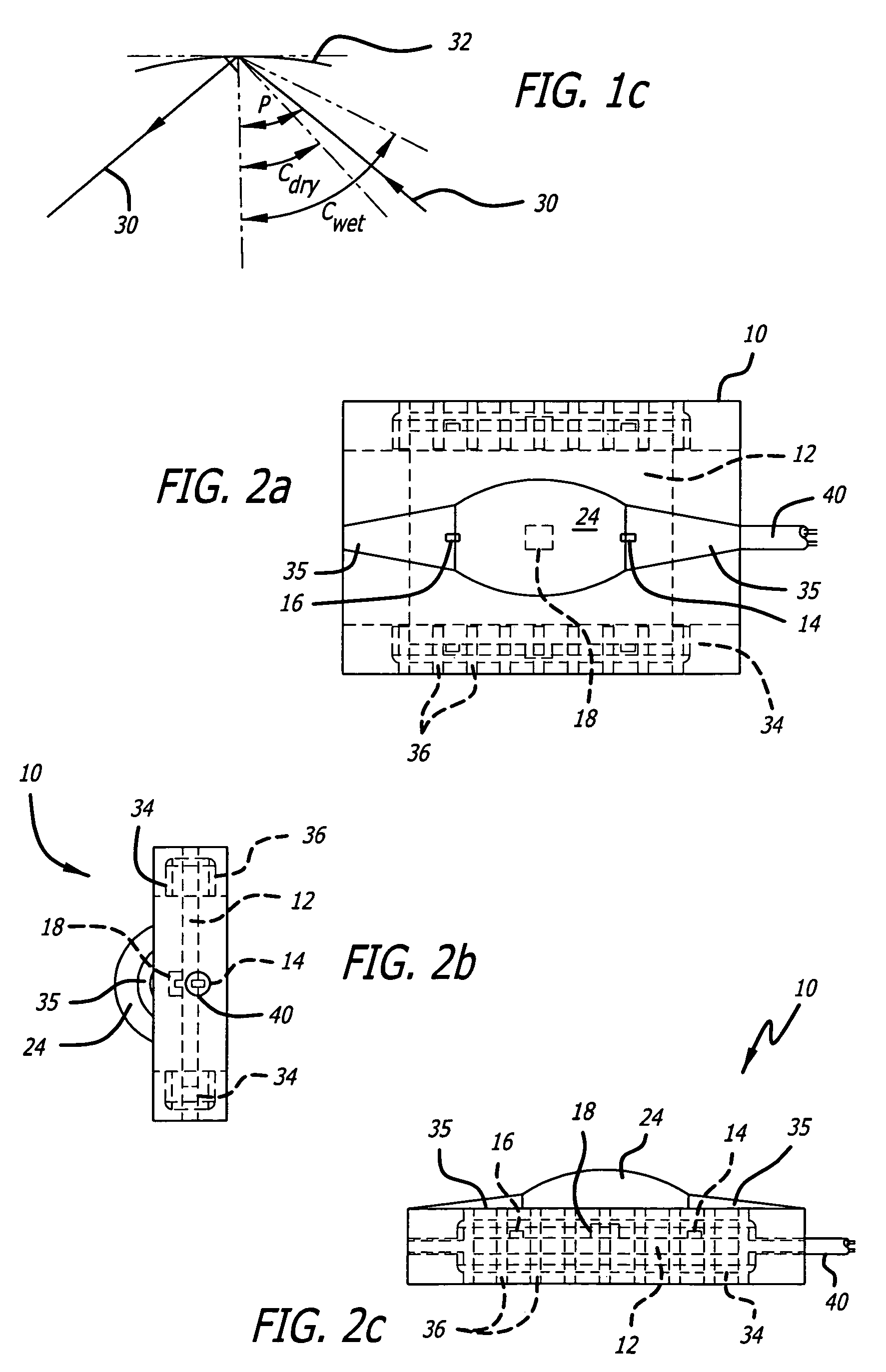

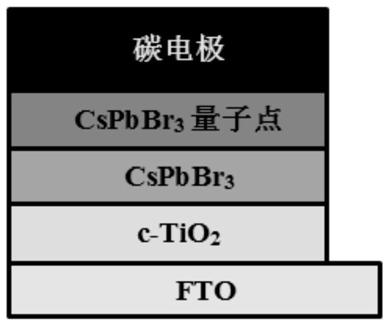

Composite light absorption layer solar cell and preparation method thereof

ActiveCN111106192AWide band gapEasy transferFinal product manufactureSemiconductor devicesTransparent electronicsMaterials science

The invention discloses a composite light absorption layer solar cell and a preparation method thereof. The composite light absorption layer solar cell comprises a transparent conductive substrate, atransparent electron transport layer, a composite light absorption layer and a carbon electrode layer which are sequentially arranged from bottom to top, and the composite light absorption layer is composed of a CsPbBr3 perovskite thin film layer and a CsPbBr3 quantum dot thin film layer which are sequentially arranged from bottom to top. The preparation method comprises the step of sequentially preparing the transparent electron transport layer, the CsPbBr3 perovskite thin film layer, the CsPbBr3 quantum dot thin film layer and the carbon electrode layer on the transparent conductive substrate, wherein the CsPbBr3 quantum dot is prepared by taking Cs2C2O4 as a cesium source. According to the composite light absorption layer solar cell, the short-circuit current density, the open-circuit voltage, the filling factor and the photoelectric conversion efficiency are improved at the same time, so that the comprehensive performance of the cell is obviously improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Light emitting semi-conductor diode (with high light output)

InactiveUS7928466B2Discharge tube luminescnet screensLamp detailsTransparent electronicsRefractive index

A light-emitting semi-conductor diode comprising a light emitting chip at least partially surrounded by a transparent electronics protecting body on which a composite layer foil is disposed, the composite layer foil includes at its side facing away from the electronics protection body a carrier layer, which has a refraction index that is greater than the refraction index of the electronics protection body and, at the opposite side, an active layer of the same material of which the electronics protecting body consists.

Owner:MERCK PATENT GMBH

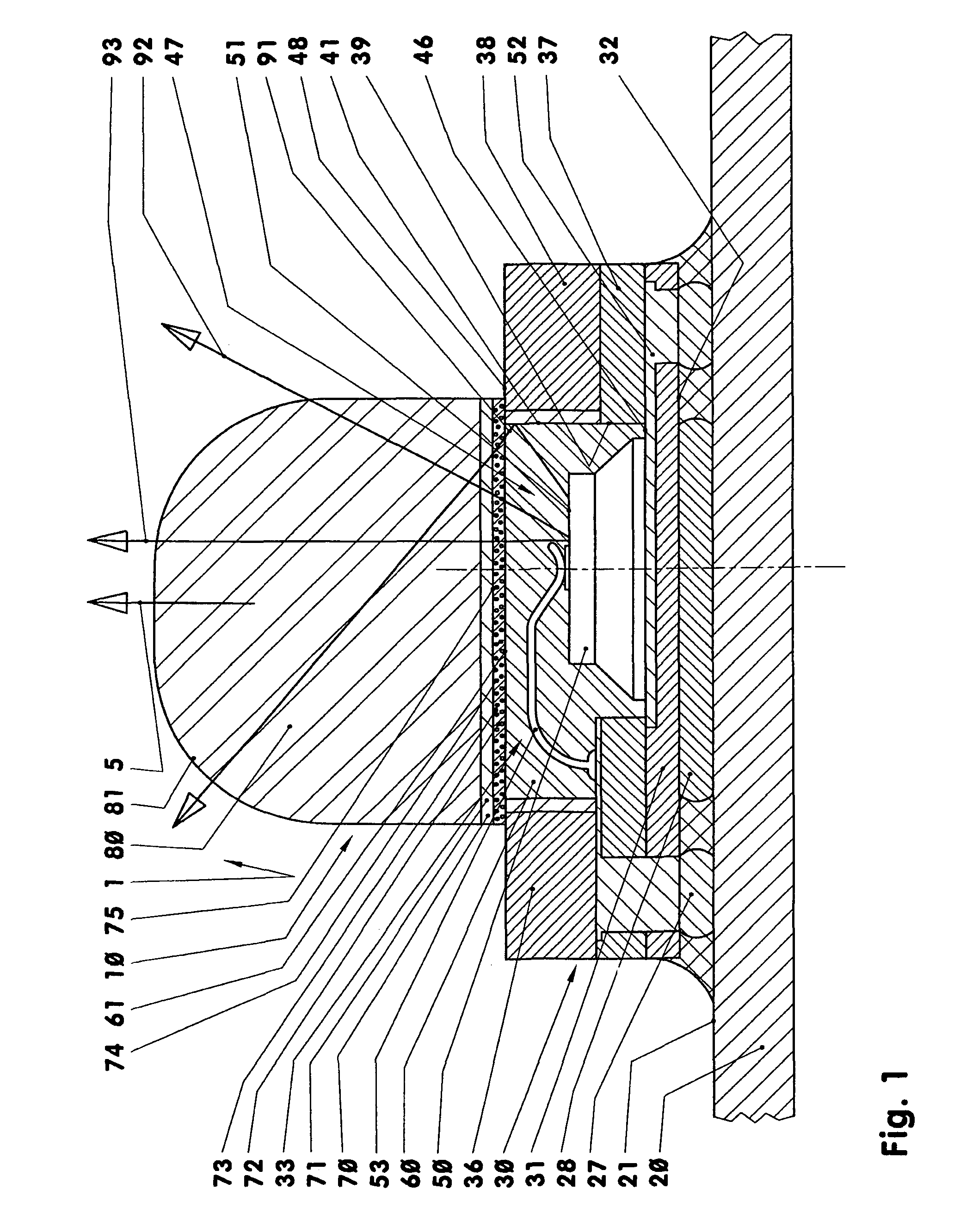

Boarding bridge provided with transparent electric bulletin board

InactiveCN104813387ACompensation for lossUniform outputElectrical apparatusElectroluminescent light sourcesElectrical resistance and conductanceEngineering

The present invention relates to a boarding bridge provided with a transparent electric bulletin board, and more specifically, a transparent electric bulletin board arranged in a boarding bridge includes a transparent electrode of which the width and the length of the pattern are adjusted according to the surface resistance so as to supply a uniform drive voltage to light emitting elements, thus making the light emitting elements emit a light with a uniform intensity.

Owner:TIANJIN CECEP BRILLSHOW

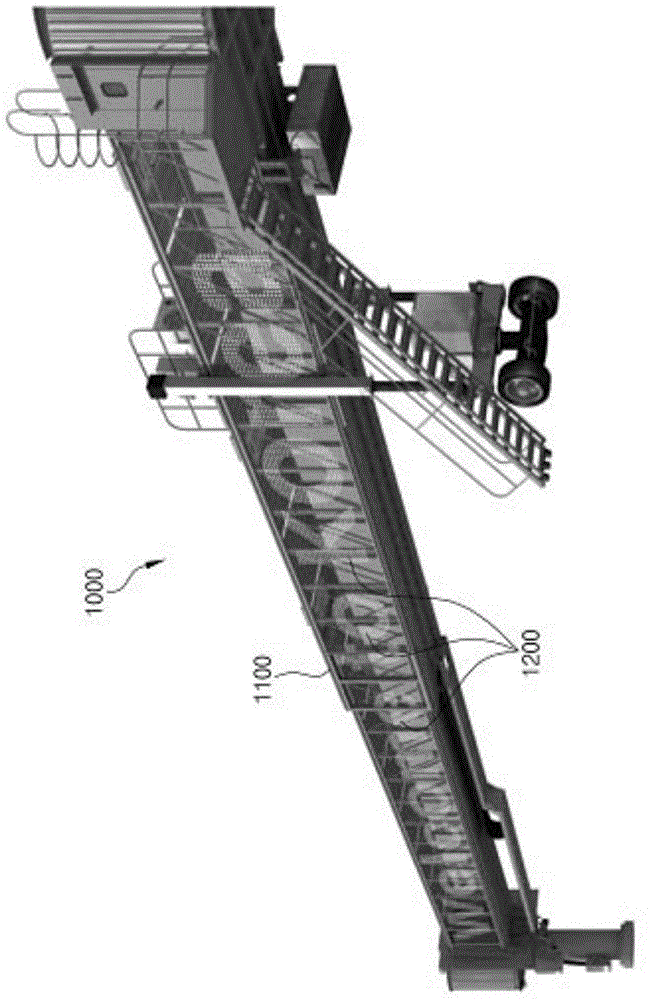

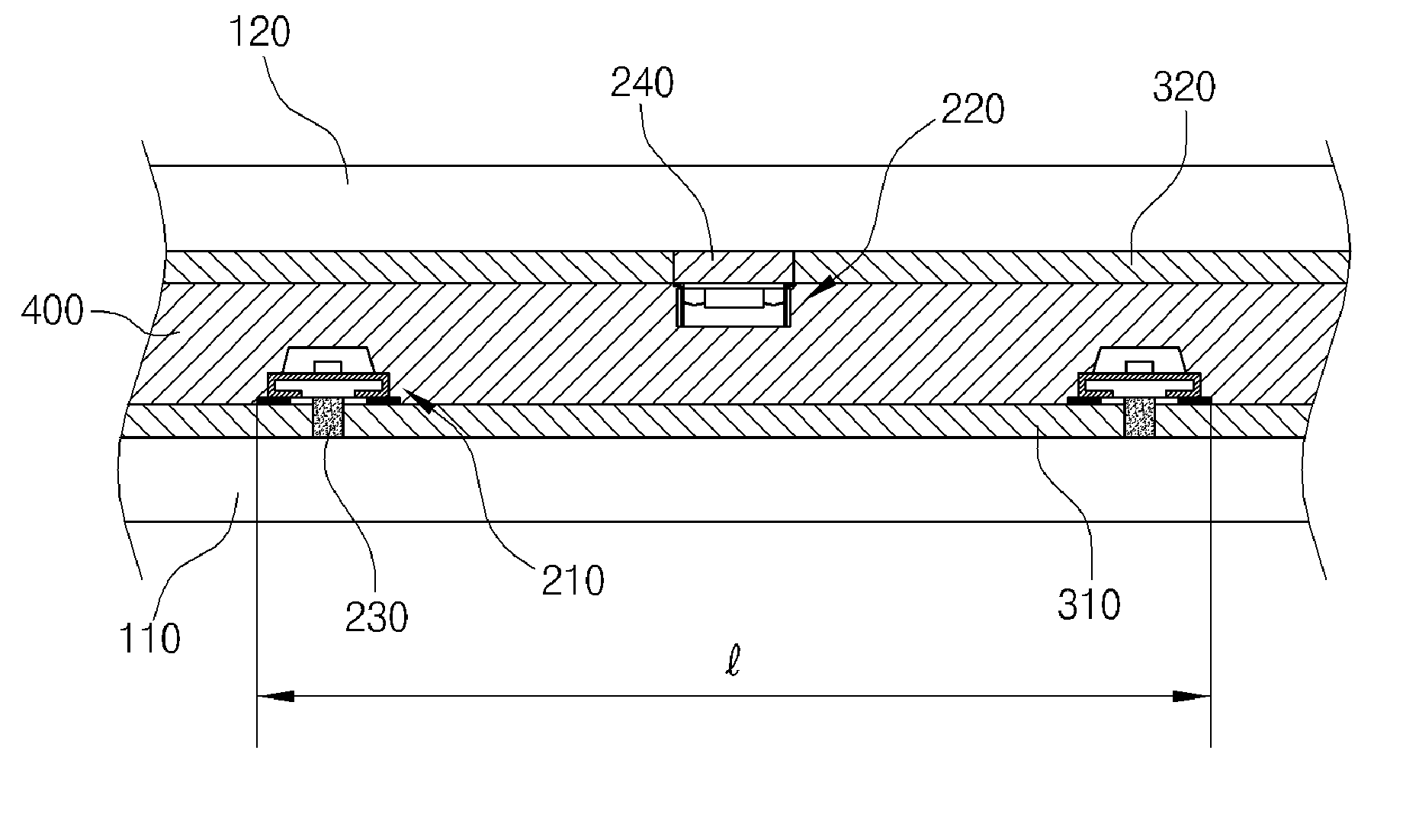

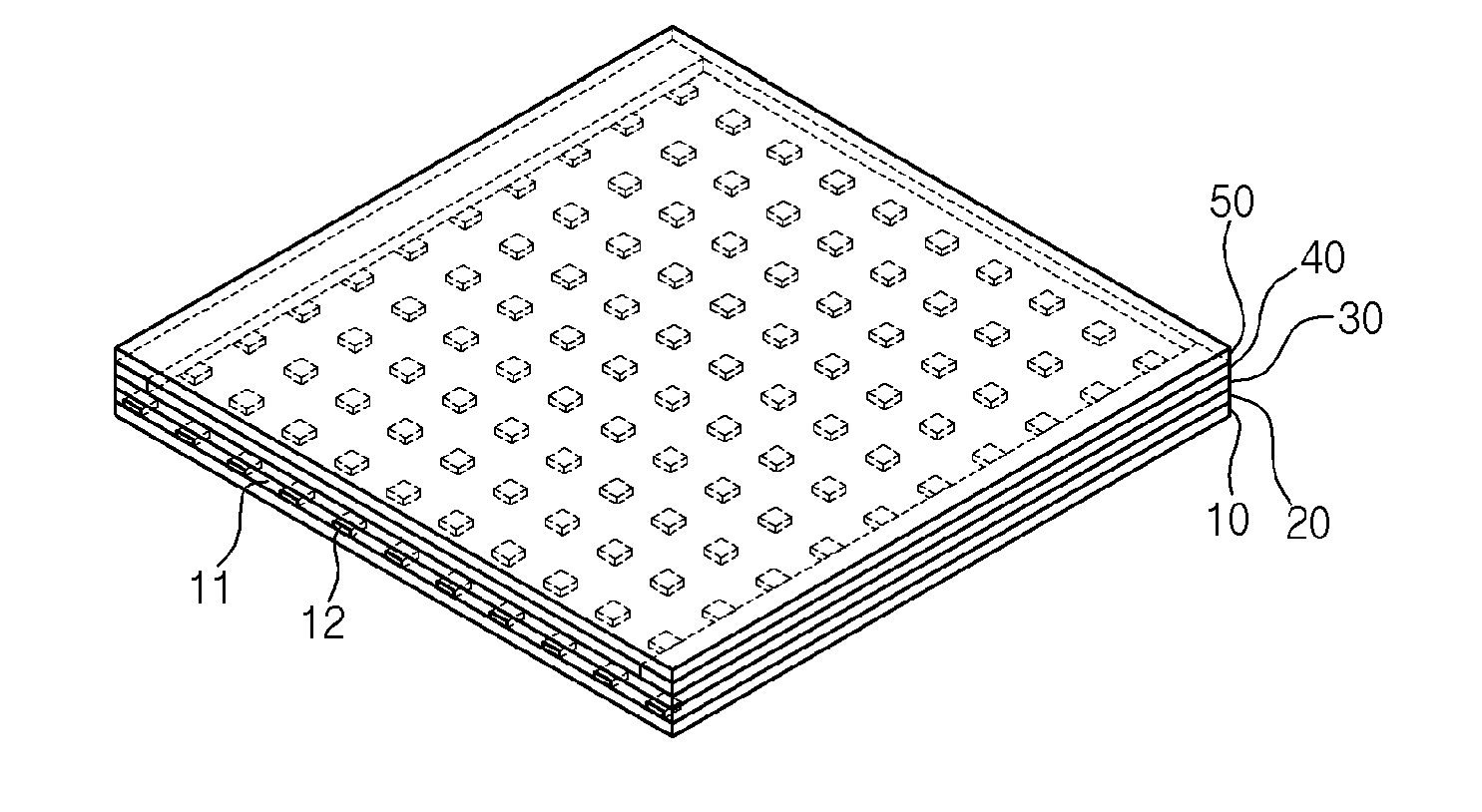

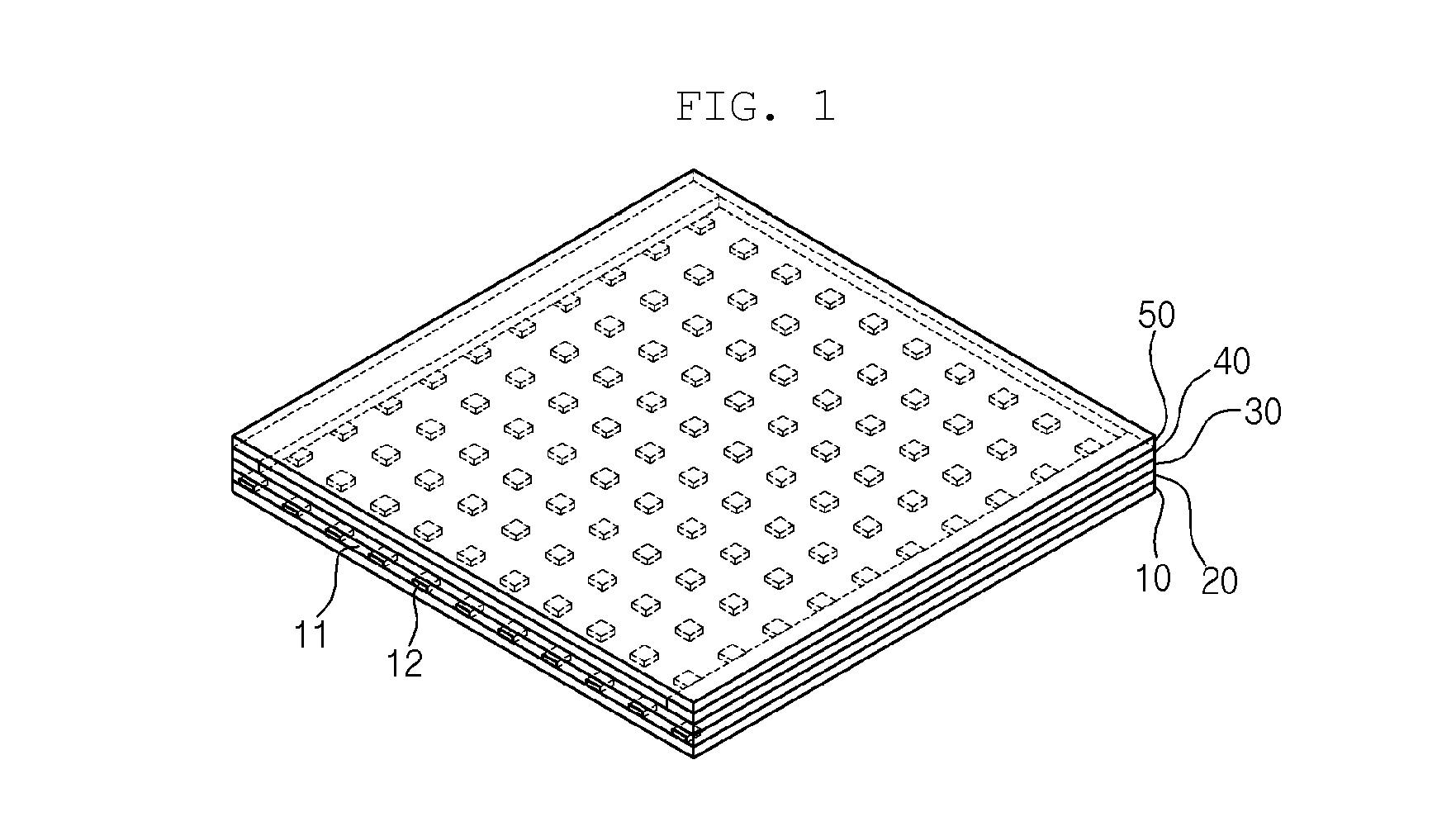

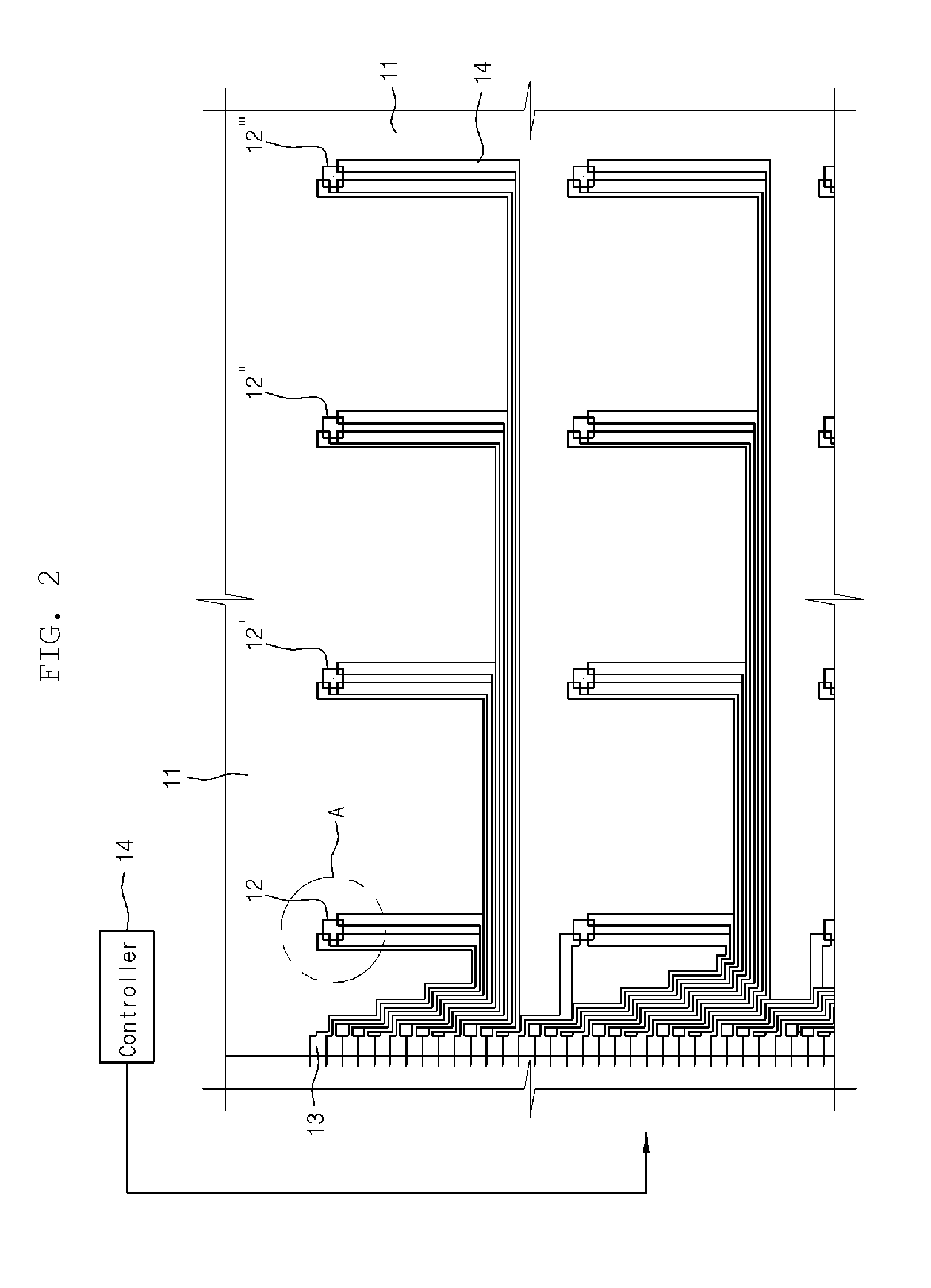

Transparent electronic display board and method for manufacturing same

ActiveUS20150176769A1Improve image qualityDistanceLaminationLamination apparatusDisplay boardElectrical and Electronics engineering

The present invention relates to a transparent electronic display board and a method of manufacturing the same. More particularly, the transparent electronic display board uses front light-emitting elements and rear light-emitting elements and / or both-sided light-emitting elements, whereby the number of light-emitting elements that can be installed in the transparent electronic display board can be increased. Thereby, the quality of an image displayed on the transparent electronic display board can be markedly improved.

Owner:G SMATT

Transparent display board with structure of double layer type and manufacturing method thereof

ActiveUS20160275831A1Low costElectrical apparatusElectroluminescent light sourcesTransparent electronicsMechanical engineering

Owner:G SMATT

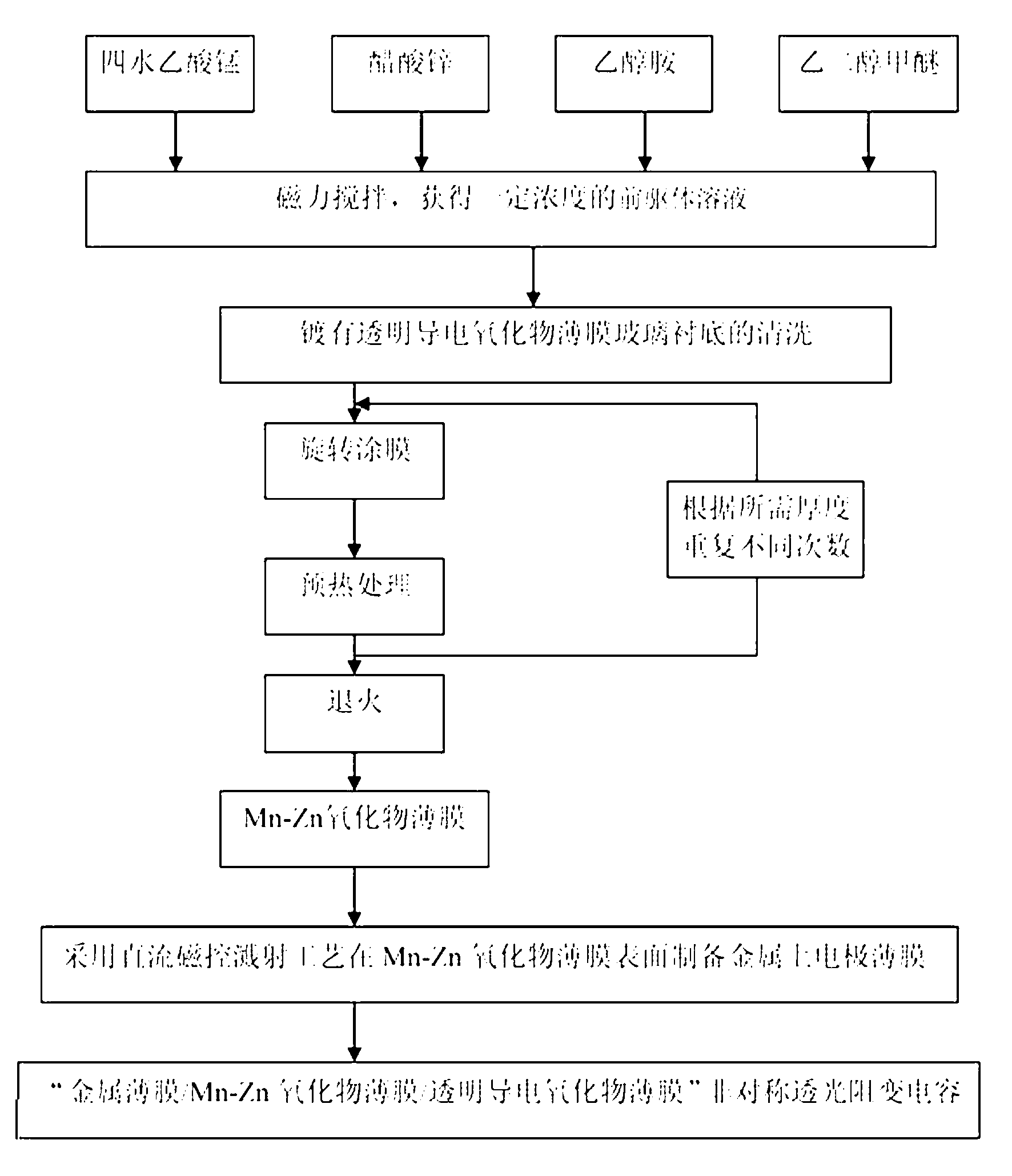

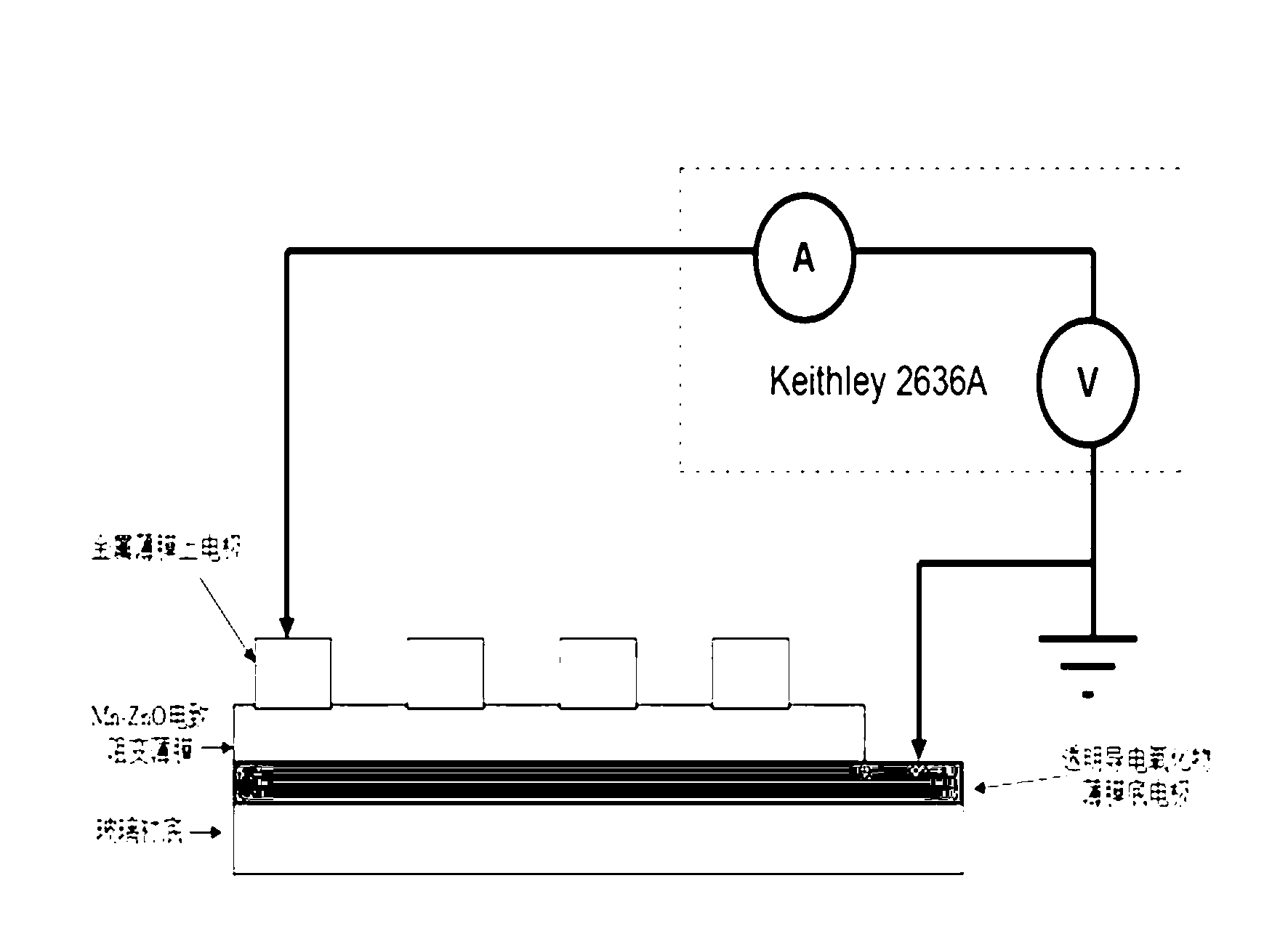

Method for preparing Mn-Zn oxide electrogenerated resistive thin films and asymmetric light-pervious resistive capacitors thereof

InactiveCN103014686APrecise control of componentsImprove fatigue resistanceLight-sensitive devicesSolid/suspension decomposition chemical coatingCapacitanceTransparent electronics

The invention discloses a method for preparing Mn-Zn oxide electrogenerated resistive thin films and asymmetric light-pervious resistive capacitors thereof, which comprises the following steps of: preparing an Mn-Zn oxide electrogenerated resistive thin film by taking glass plated with a transparent conductive oxide thin film as a substrate and using a CSD (chemical solution deposition) technique, and then by using a direct-current magnetron sputtering technique, preparing a metal thin film upper electrode and obtaining a corresponding asymmetric light-pervious resistive capacitor. The method disclosed by the invention has the advantages that (1) the components of the thin film are controlled accurately, and the components are adjusted (doped) easily, so that an effect of large area film making can be achieved, and the cost is low; (2) because a process scheme of multiple spin coating and layered preheating is adopted, the crystallinity can be improved, the internal stress of the thin film can be reduced, and the properties, especially higher high / low resistance ratio and lower setting voltage and reset voltage, of the thin film can be increased; and (3) the prepared thin film is a capacitor with an asymmetric structure, so that the anti-fatigue properties of the electrogenerated resistive thin film can be greatly improved, and the thin film can be applied to the field of transparent electronics.

Owner:GUILIN UNIV OF ELECTRONIC TECH

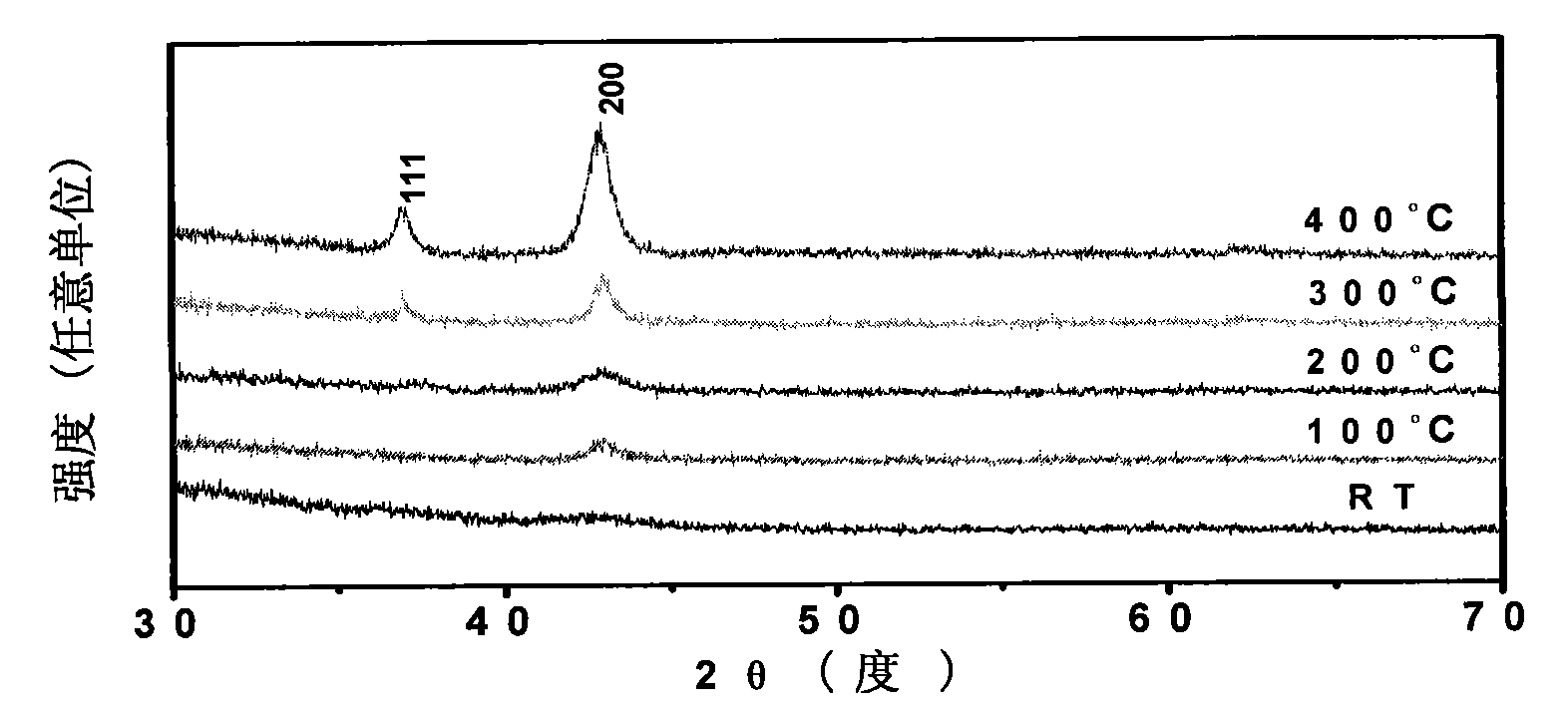

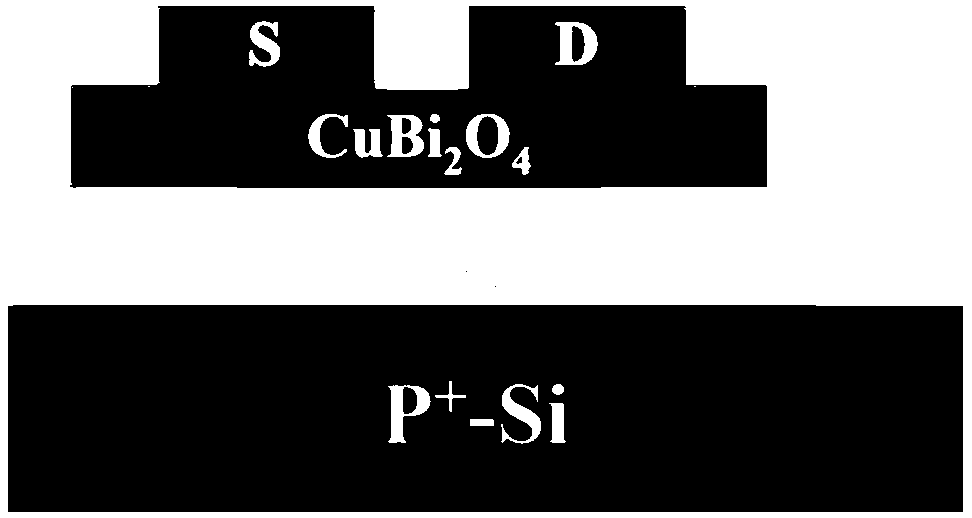

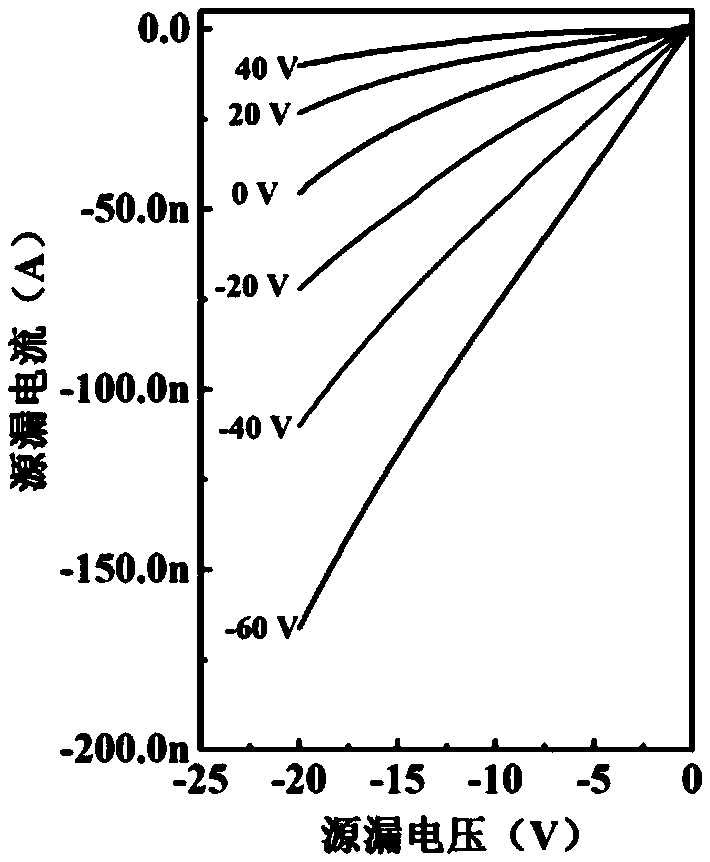

A ternary p-type CuBi2O4 thin film transistor and a preparation method thereof

ActiveCN109148593ASimple structureStable electrical modulation characteristicsTransistorSemiconductor/solid-state device manufacturingModulation functionRadio frequency magnetron sputtering

The invention belongs to the technical field of thin film transistors, in particular to a ternary p-type CuBi2O4 thin film transistor and a preparation method thereof. A p-type CuBi2O4 channel layer is prepared on a thermal oxide SiO2 substrate by a radio frequency magnetron sputtering technology, and a source / drain electrode adopts Au, Ni, Cu or ITO electrode to form a bottom gate structure typeTFT device with a certain p-type modulation function. The CuBi2O4 channel layer prepared by the invention has stable p-type semiconductor characteristics, simple device structure and compatible preparation process with microelectronics, and has wide industrial application prospects in OLED display and transparent electronic circuit.

Owner:FUDAN UNIV

Transparent imaging electronic whiteboard and interactive transparent electronic whiteboard system

InactiveCN106406450AImprove imaging clarityBright colorInput/output for user-computer interactionDigital data processing detailsWhiteboardTransparent electronics

The invention relates to a transparent imaging electronic whiteboard and an interactive transparent electronic whiteboard system. The transparent imaging electronic whiteboard comprises a first glass layer, a film interlayer and a second glass layer in sequence from the top down, wherein the first glass layer, the film interlayer and the second glass layer are all made of transparent material. The electronic whiteboard provided by the invention adopts transparent imaging glass for imaging, so that the transparent imaging electronic whiteboard has higher imaging definition and brighter color than the electronic whiteboards on the market, and thus has a wider application range.

Owner:SHANGHAI LANMOU MEDIA TECH CO LTD

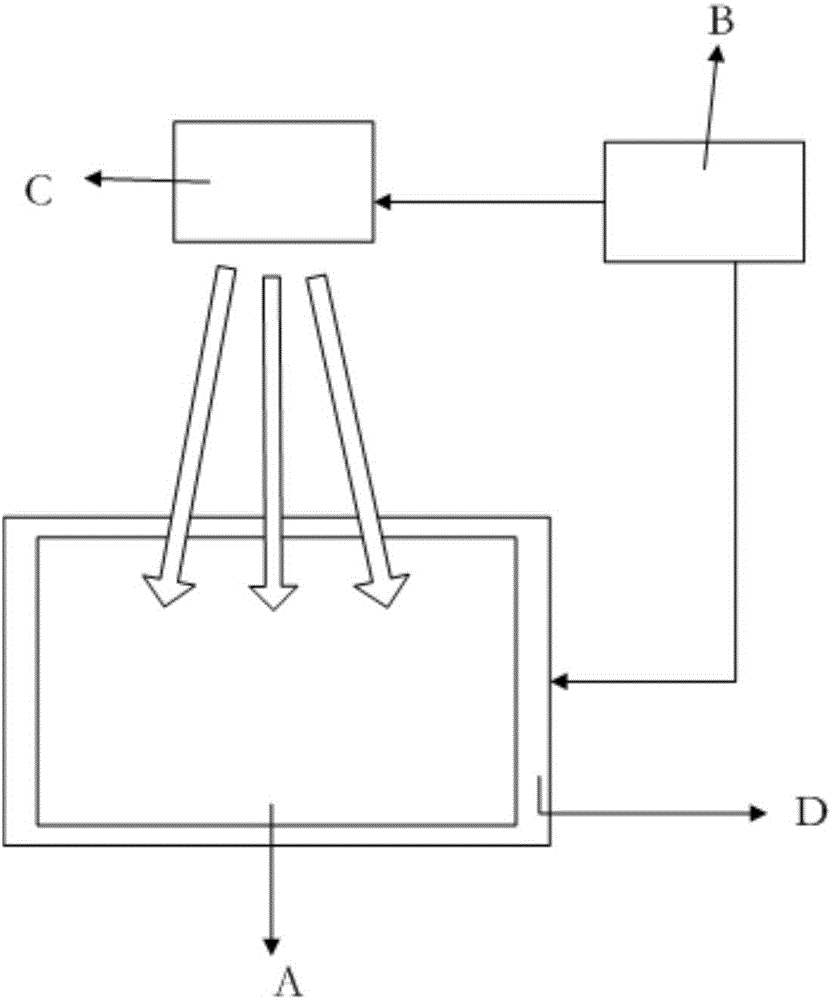

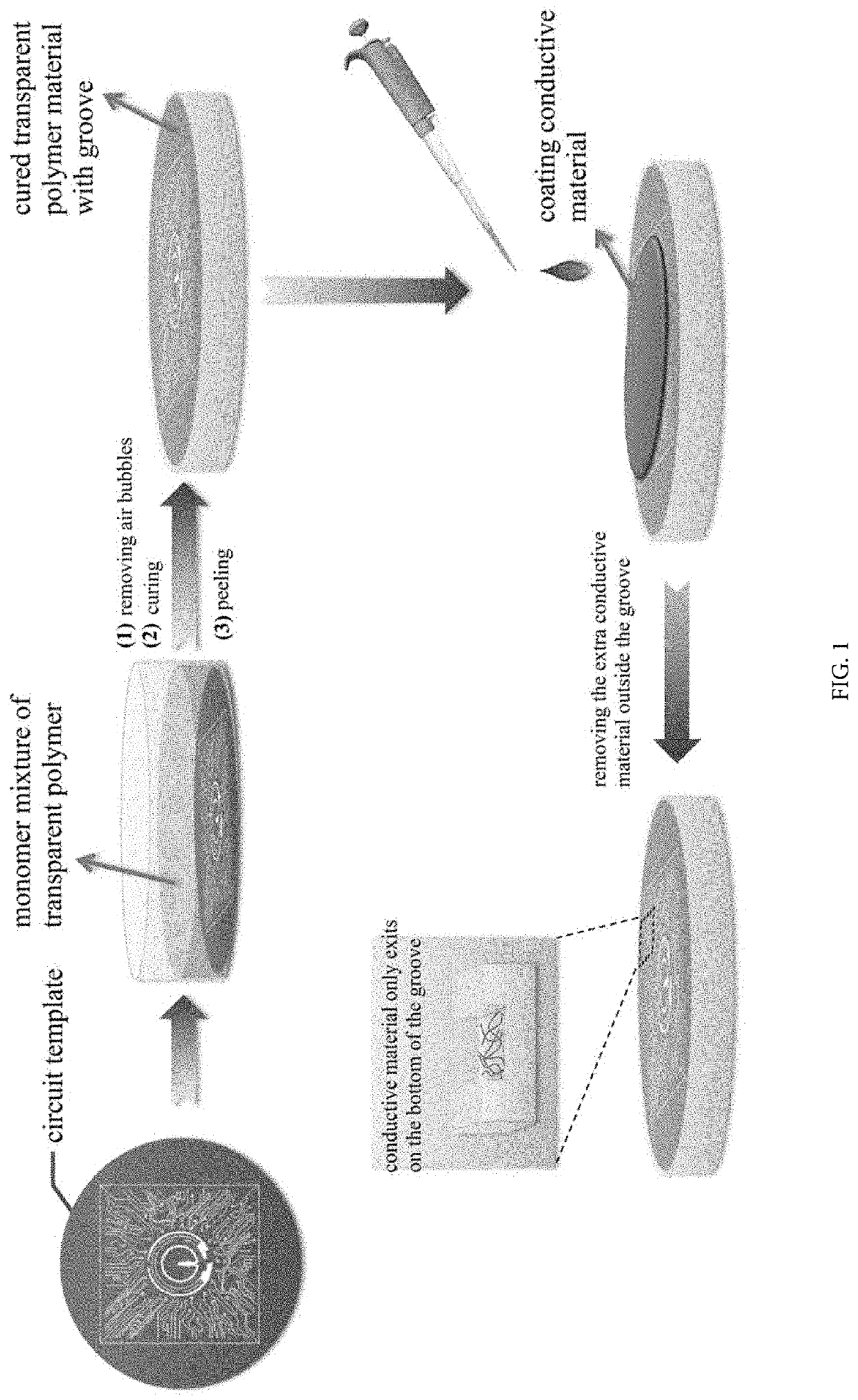

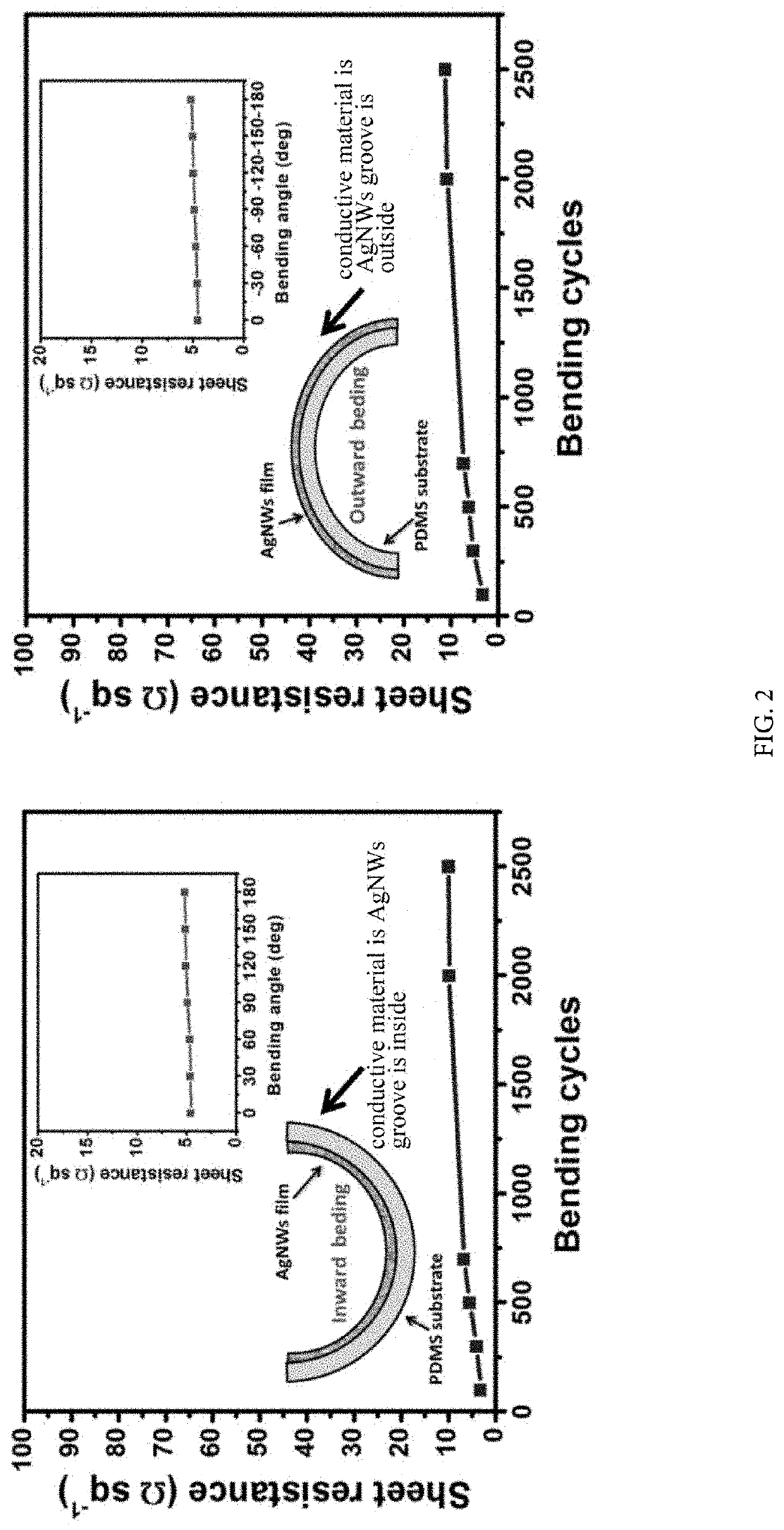

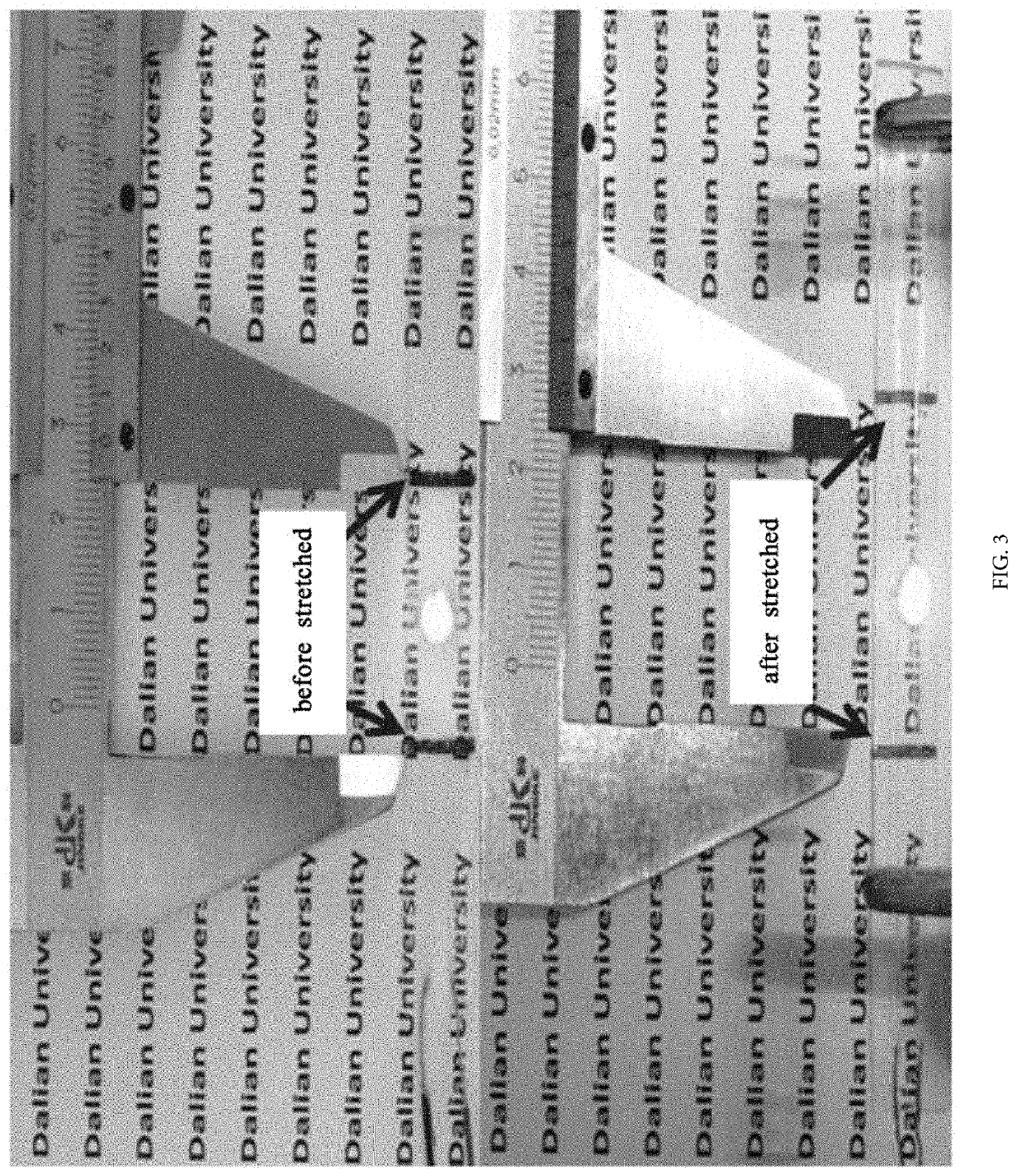

Preparation method of flexible transparent circuit

ActiveUS20200022256A1Improve conductivityEasy to bendCircuit bendability/stretchabilityTransparent dielectricsTransparent electronicsHemt circuits

A manufacturing method of a flexible transparent circuit includes preparing a circuit template. The method further includes using a flexible transparent polymer material to prepare a cured transparent carrier on the circuit template, wherein the cured transparent carrier has a groove circuit structure. The method includes coating a solution containing a conductive material in a groove of the cured transparent carrier. The method further includes forming a circuit with the high transparency and conductivity after the solvent is volatilized. The circuit are designed and manufactured according to the requirements, and the precision thereof is able to achieve the micron or nanometer level. The formed circuit is light. The circuit can be stretched, bended or twisted many times. The circuit has a good biological compatibility. The circuit manufactured by such method is expected to be applied in various fields such as smart contact lens, flexible transparent electron devices, electronic skins.

Owner:DALIAN UNIVERSITY

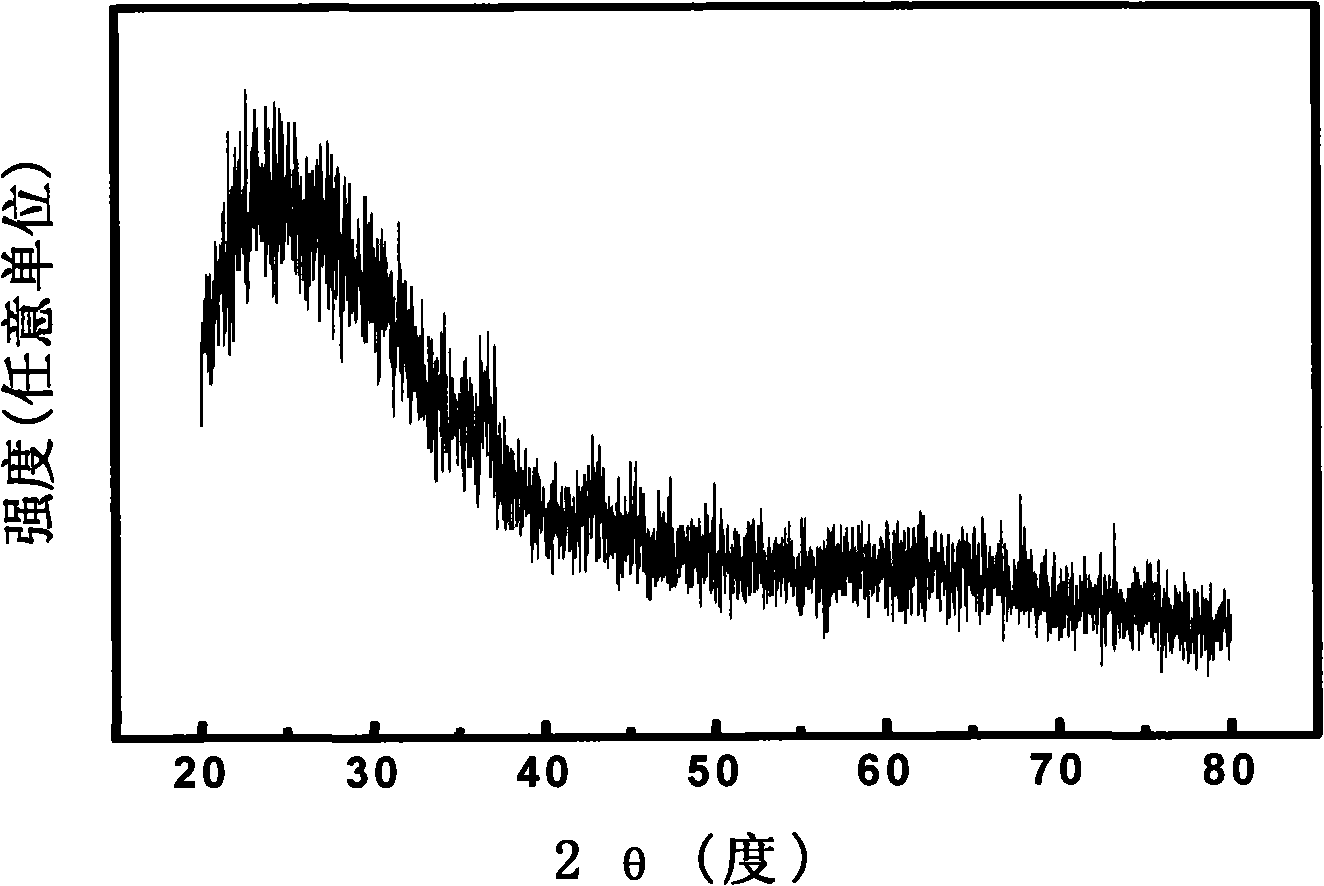

A p type conductive transparent nickel-doped CuO film and its making method

InactiveCN101262016AImprove conductivityImprove transmittanceFinal product manufactureVacuum evaporation coatingTransparent electronicsPlasma deposition

The invention pertains to the technical field of transparent conductive oxide films, more particularly relates to a P-type conductive transparent cooper oxide film doping with nickel and a preparation method thereof. Common glass is taken as a base plate o the P-type conductive transparent cooper oxide film doped with nickel and cooper oxide film doped with nickel, (Cu1-xNixO) ceramic target is utilized, under the condition that the temperature of the base plate is room temperature, the P-type conductive transparent Cu1-xNixO film with a non crystalline structure is obtained by pulsed plasma deposition (PPD) technique under the condition of proper oxygen pressure, pulsed current and pulsed voltage. The film prepared by the method has high electric conductivity and good current-illumination characteristics such as high transmissivity within the range of visible light, etc. The P-type conductive transparent oxide film obtained by the method of the invention has better application prospect in the fields of transparent electronics and novel photoelectric devices.

Owner:FUDAN UNIV

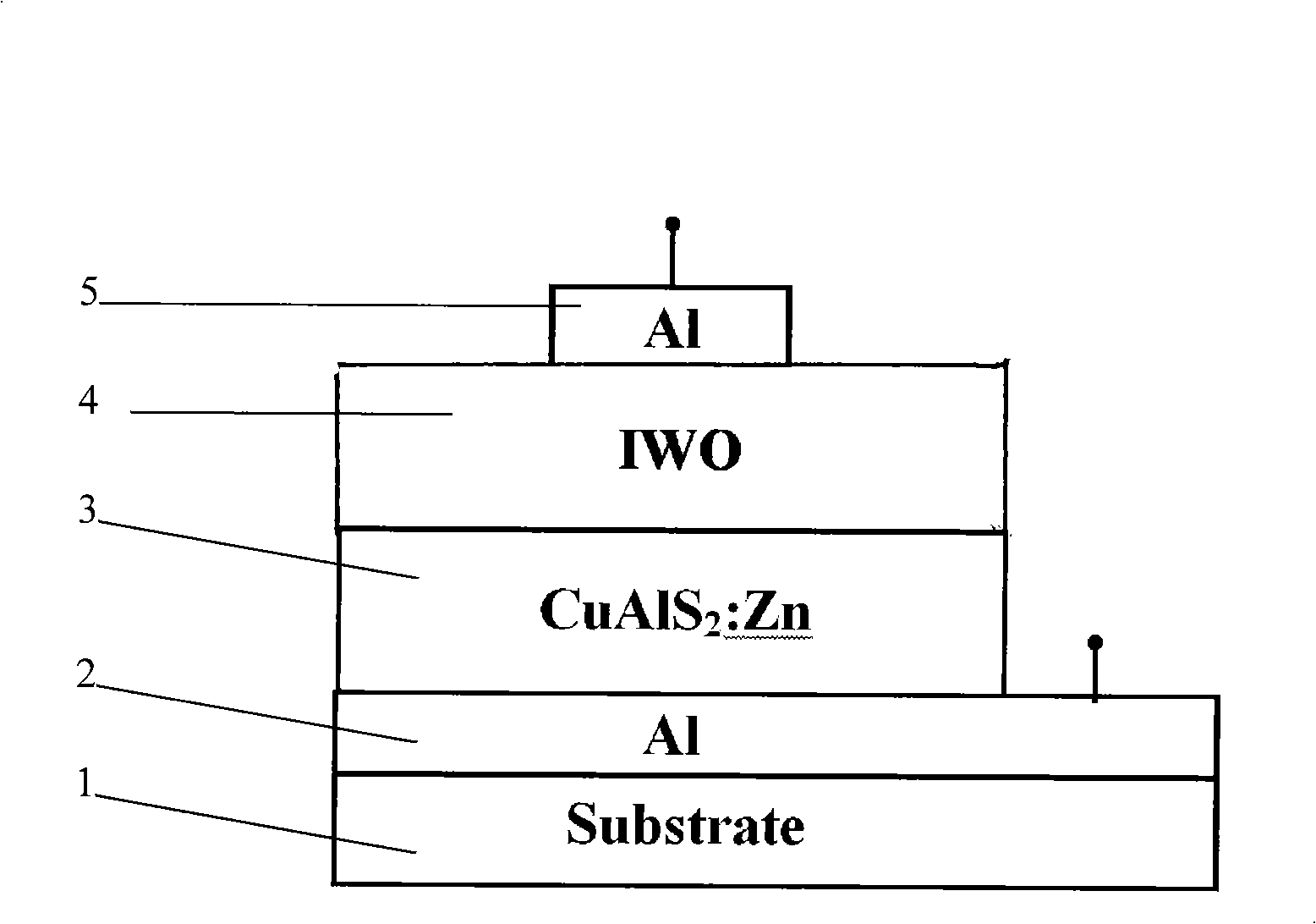

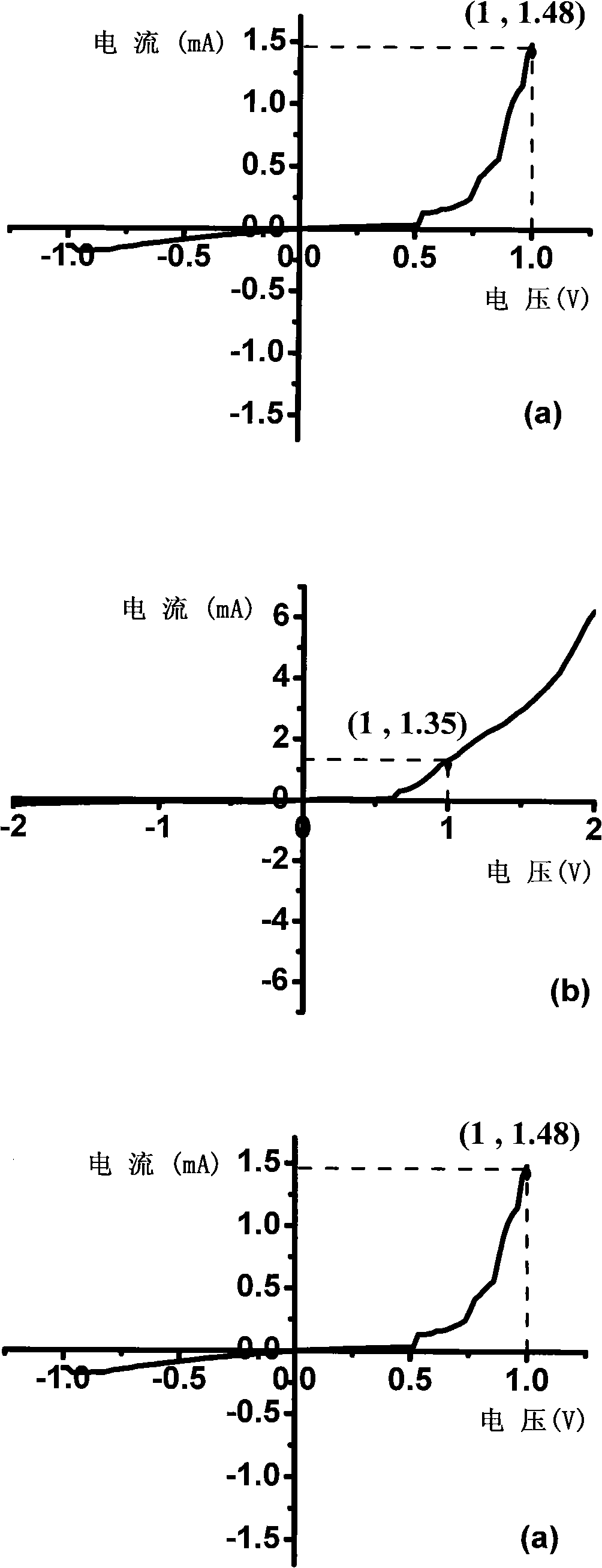

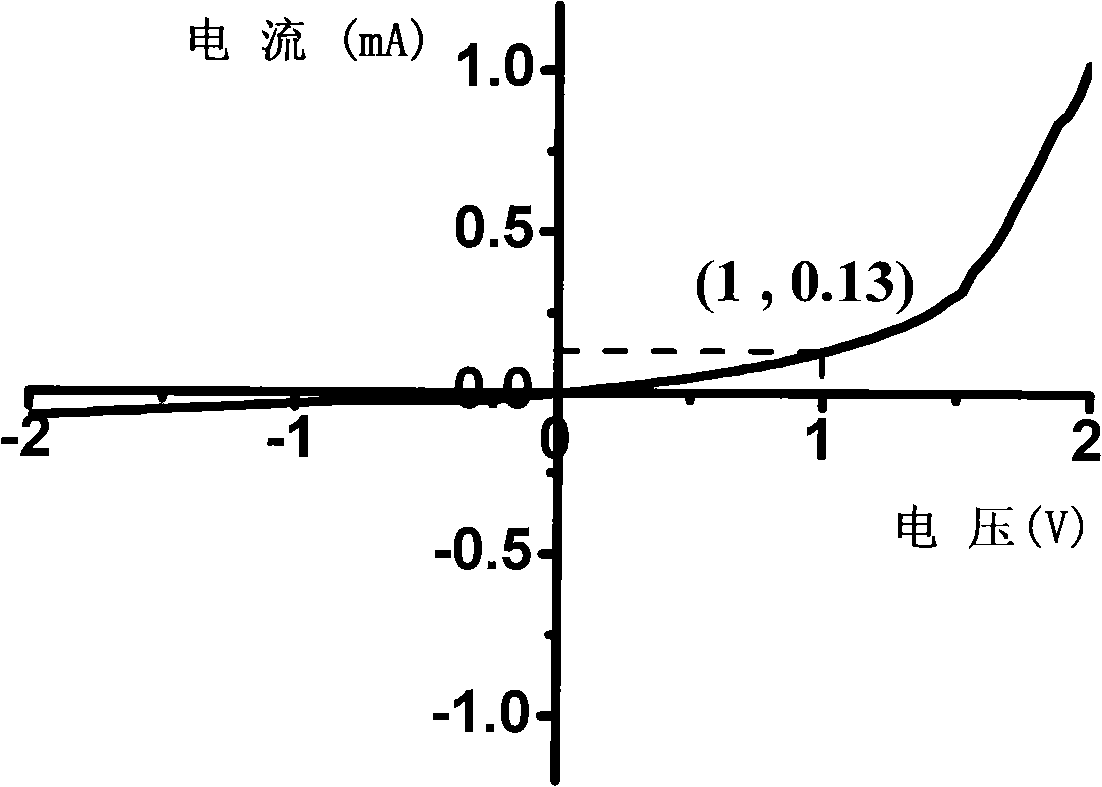

Transparent semiconductor film diode and preparing method thereof

InactiveCN101308877AHigh transparencyImprove transmittanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingHeterojunctionTransparent electronics

The invention relates to transparent electronics field and in particular relates to a transparent semiconductor film diode and a fabrication method thereof. The transparent semiconductor film diode is made by combining a p type CuALS2:Zn transparent semiconductor film with a n type In2O3:W transparent semiconductor film, thus forming a CuALS2:Zn-In2O3:W transparent semiconductor film transistor. The invention takes normal glass as the substrate, and firstly, a type CuALS2: Z film is developed through pulse plasma sedimentation plating; then a n type In2O3:W film is developed on the CuALS2:Zn film through direct magnetic control sputtering under room temperature. The film diode has good rectifying property and good transparency, thus forming a new heterojunction transparent semiconductor film diode. The transparent semiconductor film diode is of good application prospect in the field of optoelectronic devices.

Owner:FUDAN UNIV

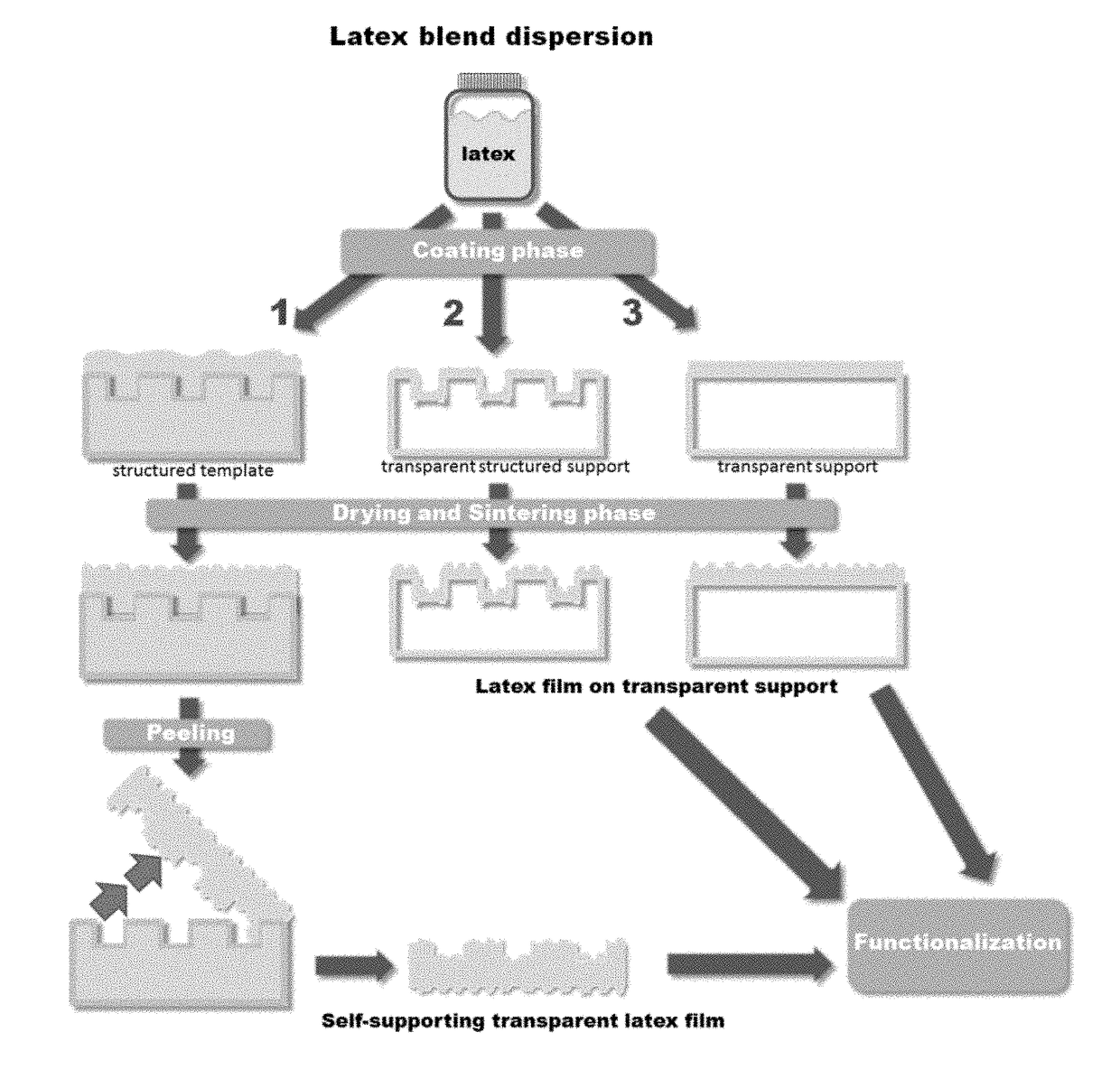

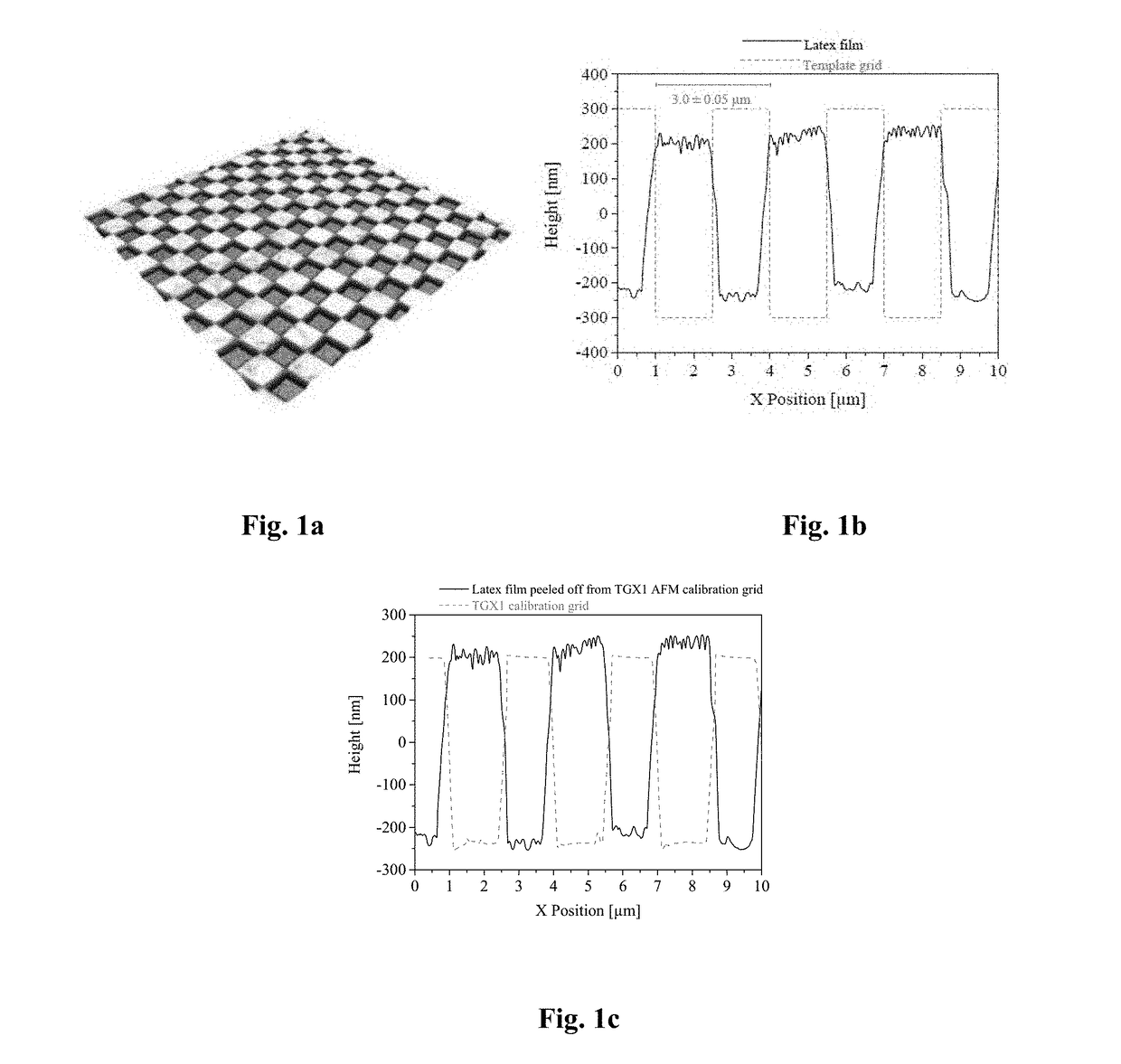

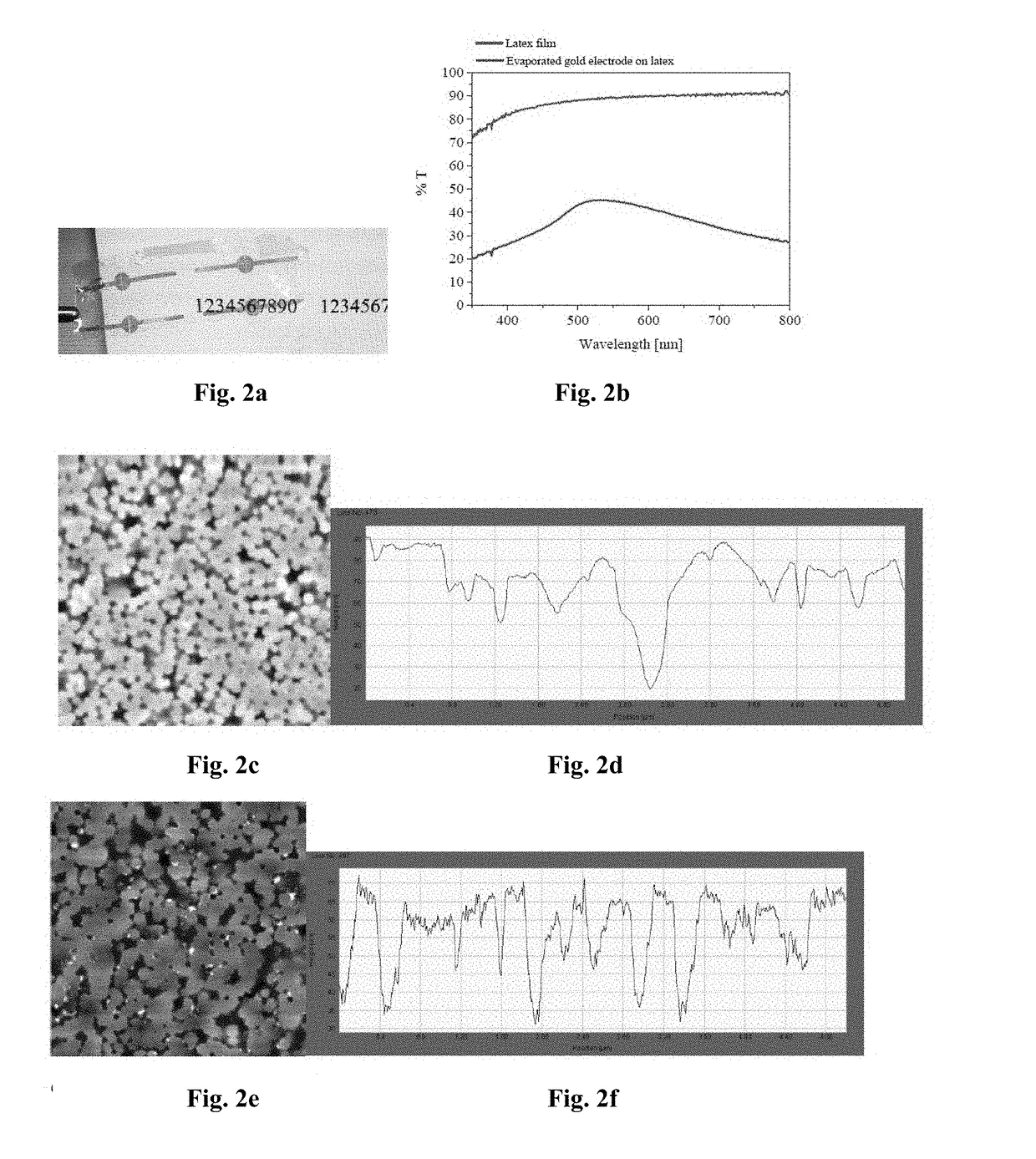

A transparent or semi-transparent nanostructured latex film for flexible and semi-transparent electronics for monitoring and manipulating cellular processes

InactiveUS20180237602A1Induce decisionInduce processBioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteControl cell

Functionalized substrates with properties that can control cell-substrate interactions, induce cellular processes and decisions by means of passive and active control to enhance cell proliferation, cell migration and wound healing are provided. By including a sensing electrode on the substrate, it is possible to measure the metabolites of cells or follow the migration of additives like drug molecules in real-time. The present technology provides a new cell culture and imaging platform composed of a transparent and chemically and topographically customized latex film with electrodes that enable real-time measurement of e.g. pH and ion concentration in the cell medium as well as the metabolic states of the cells.

Owner:BO AKAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com