A p type conductive transparent nickel-doped CuO film and its making method

A conductive transparent, copper oxide technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problem of low energy conversion efficiency and achieve the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

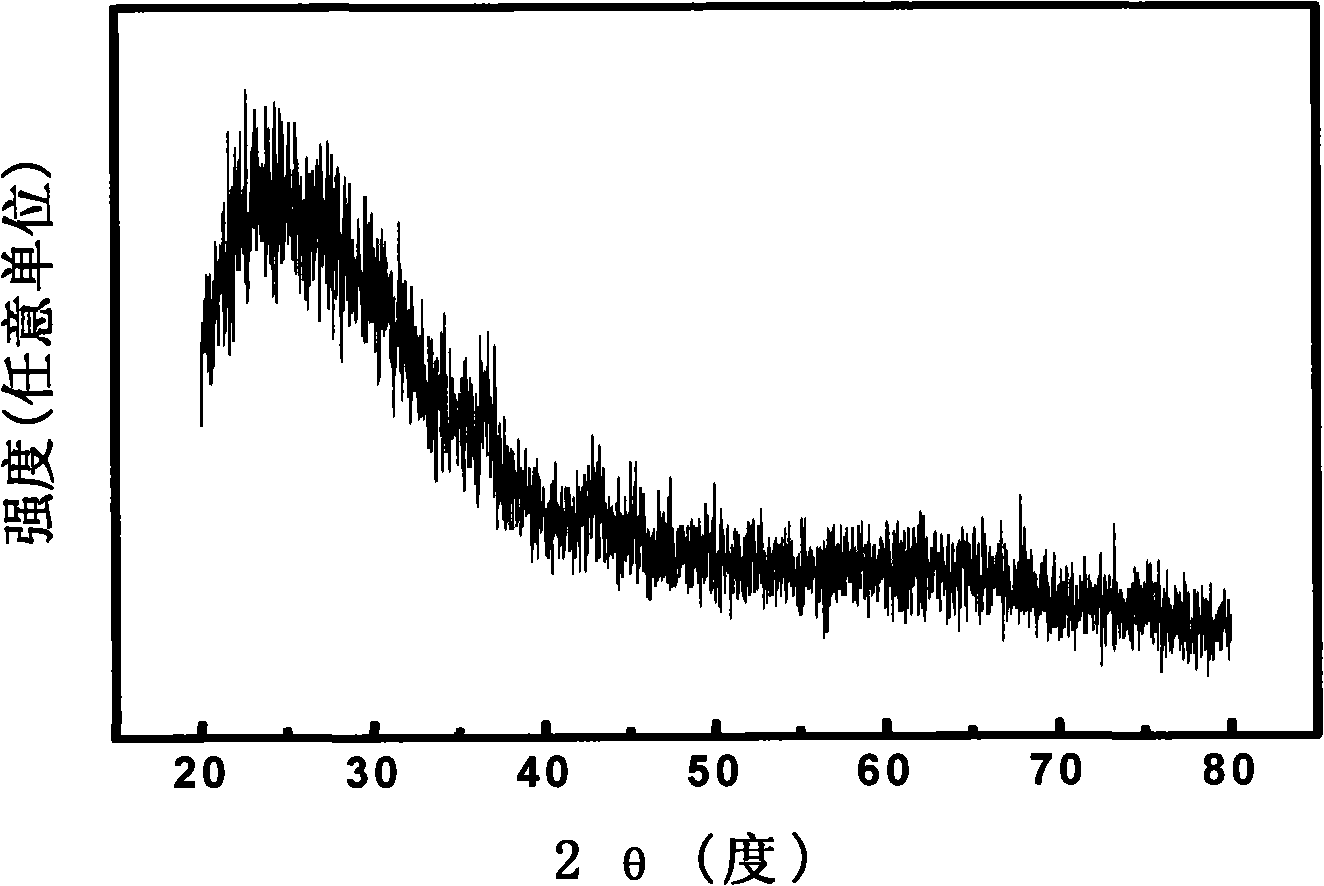

Method used

Image

Examples

Embodiment 1

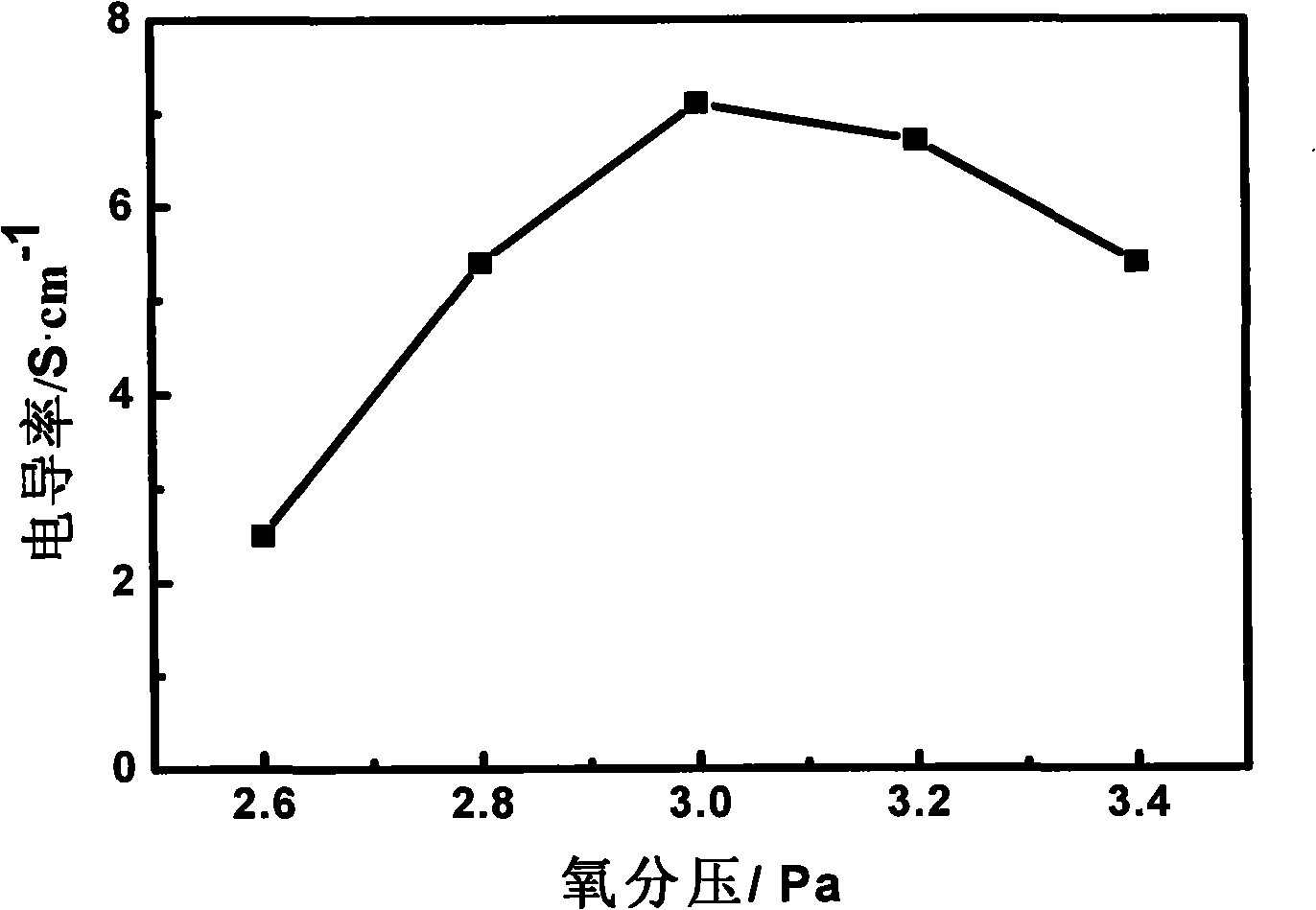

[0021] Example 1, prepare Cu with a certain chemical dosage ratio according to the traditional ceramic target preparation method 0.95 Ni 0.05 O circular target with a target diameter of 23.4 mm. The substrate is a common glass slide, which is ultrasonically cleaned with deionized water, acetone and alcohol for 20 minutes each. The distance between the target surface and the quartz tube was fixed at 4 mm, and the inner diameter of the quartz tube was 2 mm.

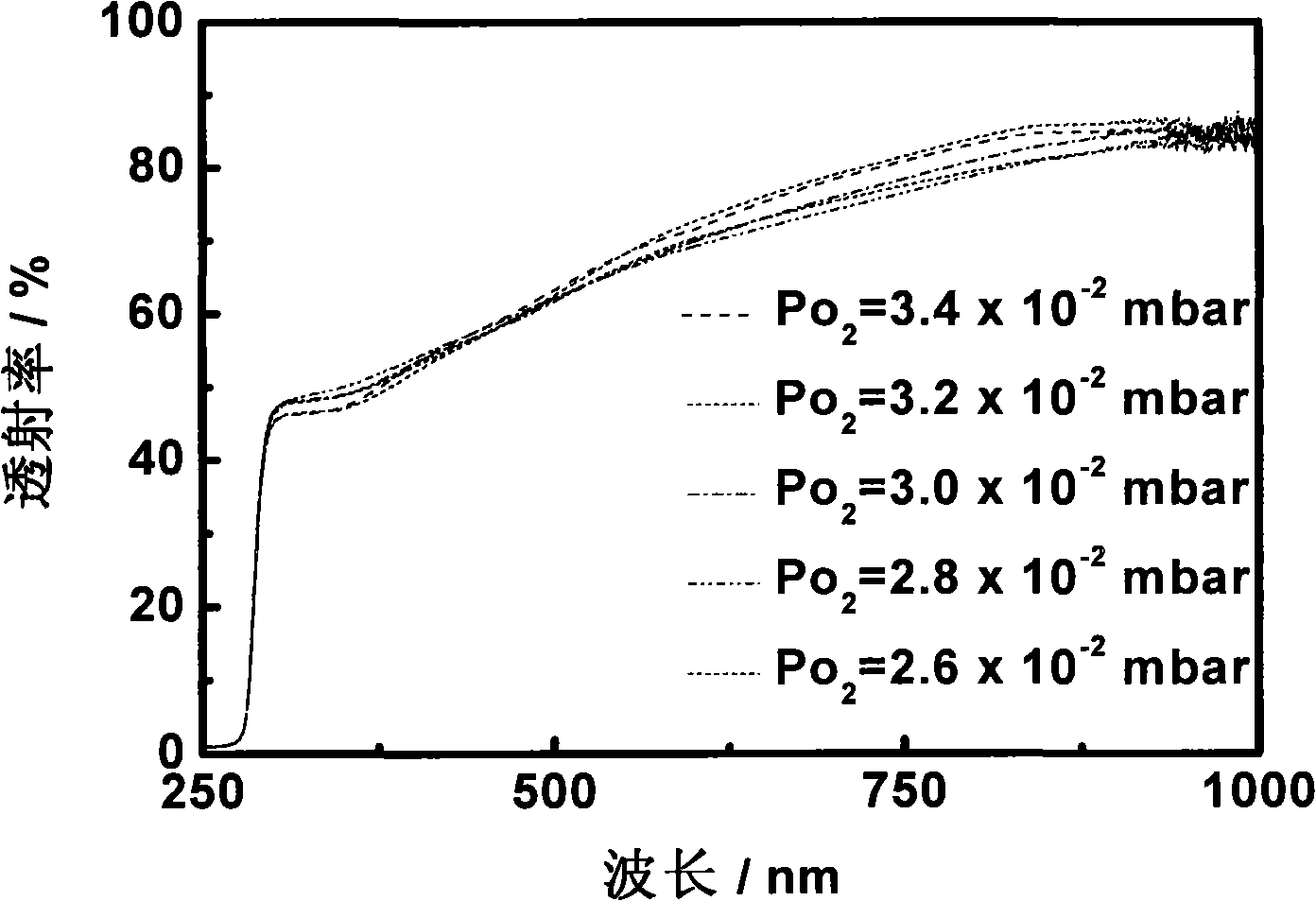

[0022] The background pressure of the vacuum chamber before film deposition was 2.0×10 -4 Pa, the substrate temperature is 30°C, set O 2 For the working air pressure, the mass flowmeter of Bronkhorst Company is used to control its flow, so that the working air pressure is 3.0Pa, and the temperature of the substrate is measured by the Eliwell EWTQ 915 thermocouple. -18.0KV and 4.5mA, the frequency of the pulsed electron beam is 2.0Hz, and the film is prepared on a common glass plate. The film deposition time is 20 minut...

Embodiment 2

[0023] Embodiment 2, the same method as embodiment 1 prepares Cu 0.95 Ni 0.05 O ceramic target, Cu was prepared under the following conditions 0.95 Ni 0.05 O film: the background pressure of the vacuum chamber before film deposition is 2.0×10 -4 Pa, the substrate temperature is 30°C, and the set working pressure is O 2 It is 3.0Pa, the operating voltage and current are -17.0KV and 4.5mA respectively, and the frequency of the pulsed electron beam is 2.0Hz. The film deposition time is 20 minutes, the film thickness is 80nm, and the conductivity is 5.9S cm -1 , the average transmittance in the visible region is higher than 65%.

[0024] A Kosaka ET3000 surface profiler was used to measure the film thickness, a BD-90 four-probe instrument was used to measure the film sheet resistance and target resistivity, and a Shimadzu UV2450 UV / Visible spectrophotometer was used to measure the film transmission spectrum. The conductive properties of the target and film were qualitatively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com