Method for preparing high-resistance transparent zinc oxide (ZnO) thin film by utilizing direct current magnetic control sputtering equipment

A high-resistance, thin-film technology, used in sputtering, metal material coating, vacuum evaporation, etc., can solve problems such as difficulty in large-scale production, affecting the performance of solar cells, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Adopt rich Zn (or lack O 2 ) ZnO target material (application in another case), using DC magnetron sputtering, ordinary glass as the substrate, and the background vacuum is pumped to 2.0×10 -4 Pa, with high purity argon as the working gas, and a small amount of O 2 (O 2 The volume percentage of the total gas flow is 0.5%), the working pressure is maintained at 1.2Pa, the distance between the target and the substrate is set to 7cm, the sputtering power is 80W, and the deposition time is 40min. In addition, for the sake of comparison, a commercial intrinsic ZnO ceramic target was used, and the radio frequency magnetron sputtering method was used to sputter for 60 minutes under the same background vacuum, atmosphere, pressure, and target distance. The thickness of the film samples prepared under the two conditions are both 800 nm.

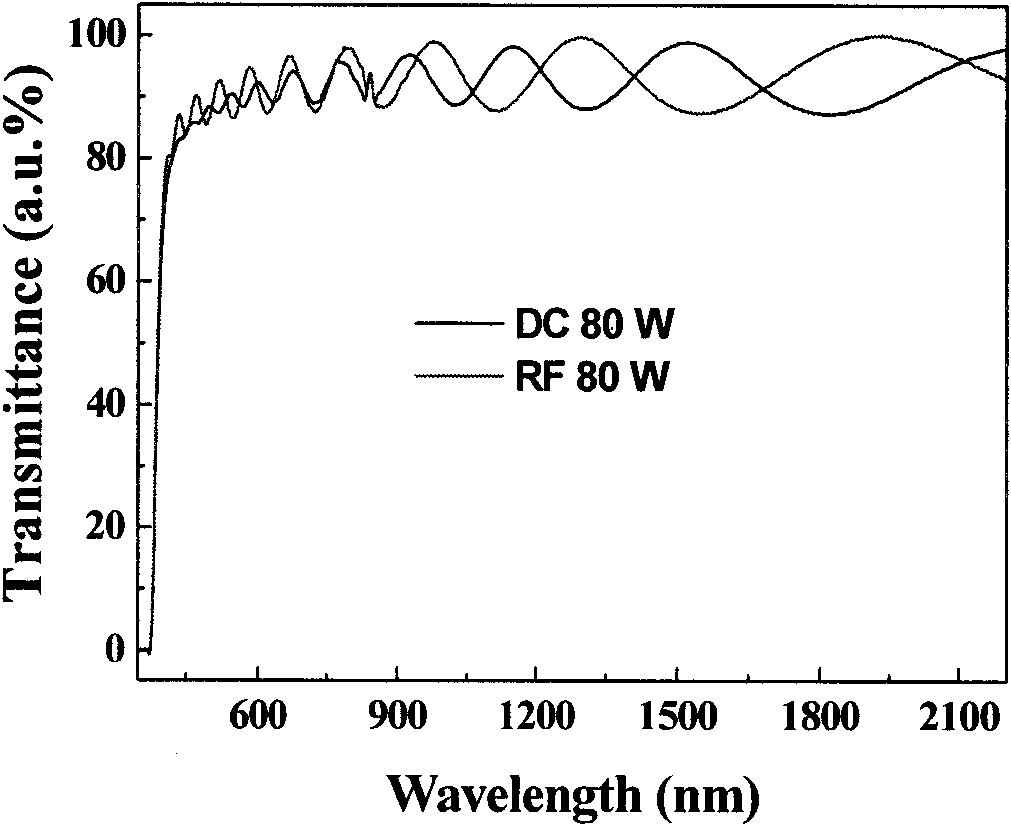

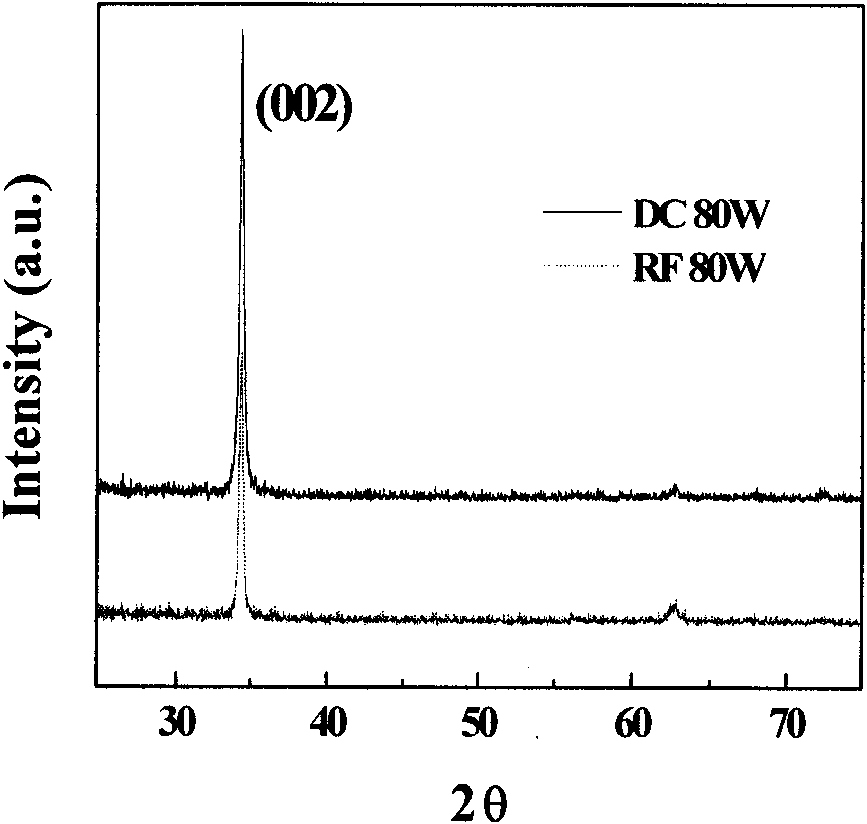

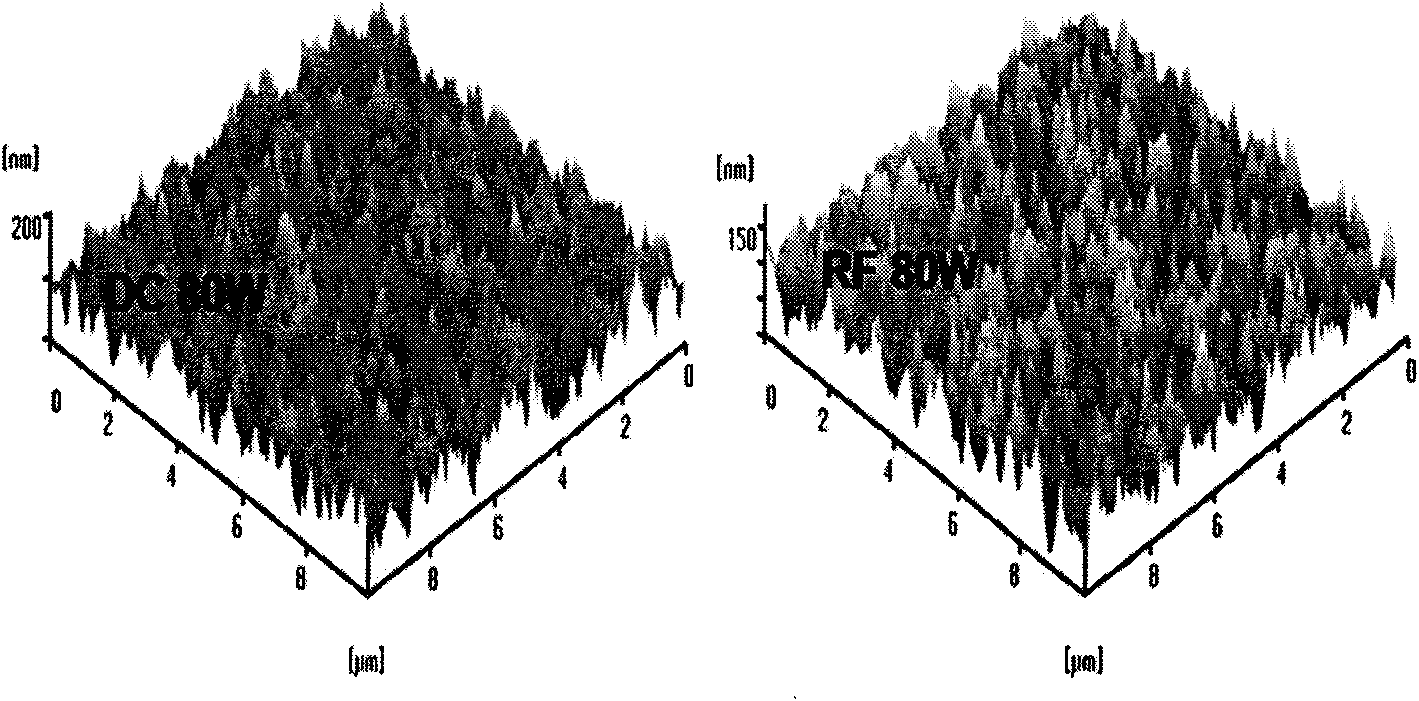

[0027] figure 1 The transmission spectra of the ZnO film samples prepared under the two conditions. It can be seen that the average transmittance...

Embodiment 2

[0030] In the application of thin-film solar cells and optoelectronic devices, the thickness of the high-resistance ZnO film is generally controlled between 60 and 120 nm. In this example, sintering at a sintering temperature of 850°C for 20 hours was used to obtain zinc-rich Zn 1.13 O-structure wide-gap ceramic material target material, using DC magnetron sputtering, ordinary glass as the substrate, the background vacuum is pumped to 2.0×10 -4 Pa, with high purity argon as the working gas, and a small amount of O 2 (O 2 0.5% of the total gas flow), the working pressure is maintained at 1.2Pa, the distance between the target and the substrate is set to 7cm, the sputtering power is 80W, and the deposition time is 4min. The thickness of the prepared film sample is 80nm.

[0031] Figure 5 For the transmission spectrum of the prepared ZnO film sample, it can be seen that the average transmittance of the film in the visible light region reaches nearly 90%, and even in the near-infrare...

Embodiment 3

[0033] Adopt rich Zn (or lack O 2 ) ZnO target material, using DC magnetron sputtering, ordinary glass as the substrate, the background vacuum is pumped to 2.0×10 -4 Pa, using pure high-purity argon as the working gas, the working pressure is maintained at 1.2 Pa, the distance between the target and the substrate is set to 7 cm, the sputtering power is 80 W, and the deposition time is 4 min. The thickness of the prepared film sample is 80nm. The electrical performance test results show that the resistivity of the sample prepared under the conditions of this embodiment is about 7×10 5 Ω·cm, slightly lower than Example 2, the average transmittance from visible light to near-infrared region (400-2200nm) is about 90%, which is equivalent to Example 2, which is in line with the thin film solar cell window layer, diffusion barrier layer and others Application requirements for optoelectronic devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com