Gallium-molybdenum-codoped indium tin oxide ceramic target, gallium-molybdenum-codoped indium tin oxide transparent conductive film and preparation method

A technology of transparent conductive film and indium tin oxide, which is applied in the field of sputtering targets, can solve the problems of unstable ITO conductive film, failure to meet the use requirements, low film transmittance, etc., and achieve excellent electrical and optical properties, Good weak acid etching performance and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

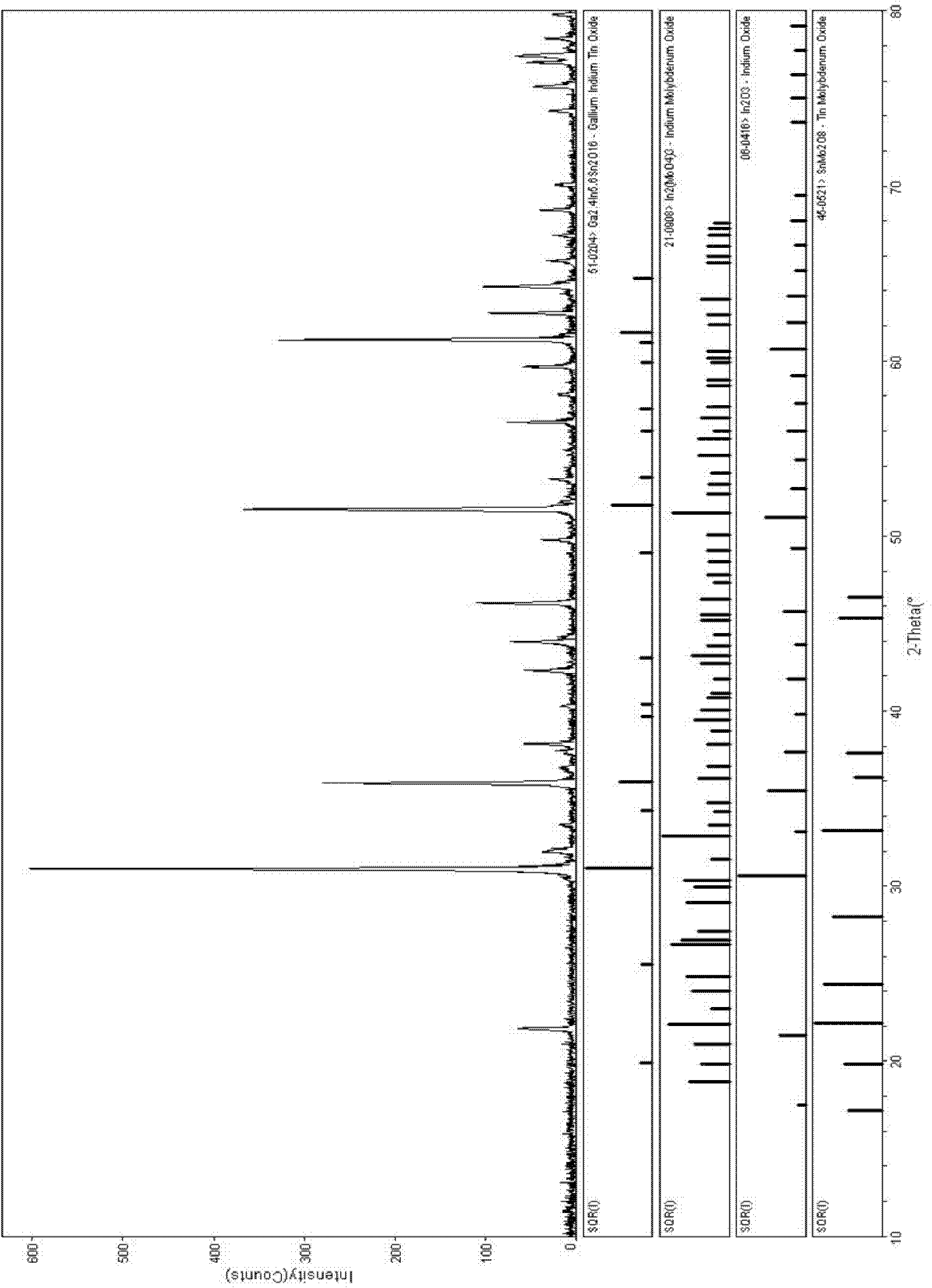

[0020] (1) Preparation of gallium molybdenum co-doped indium tin oxide (InSnGaMo) ceramic target

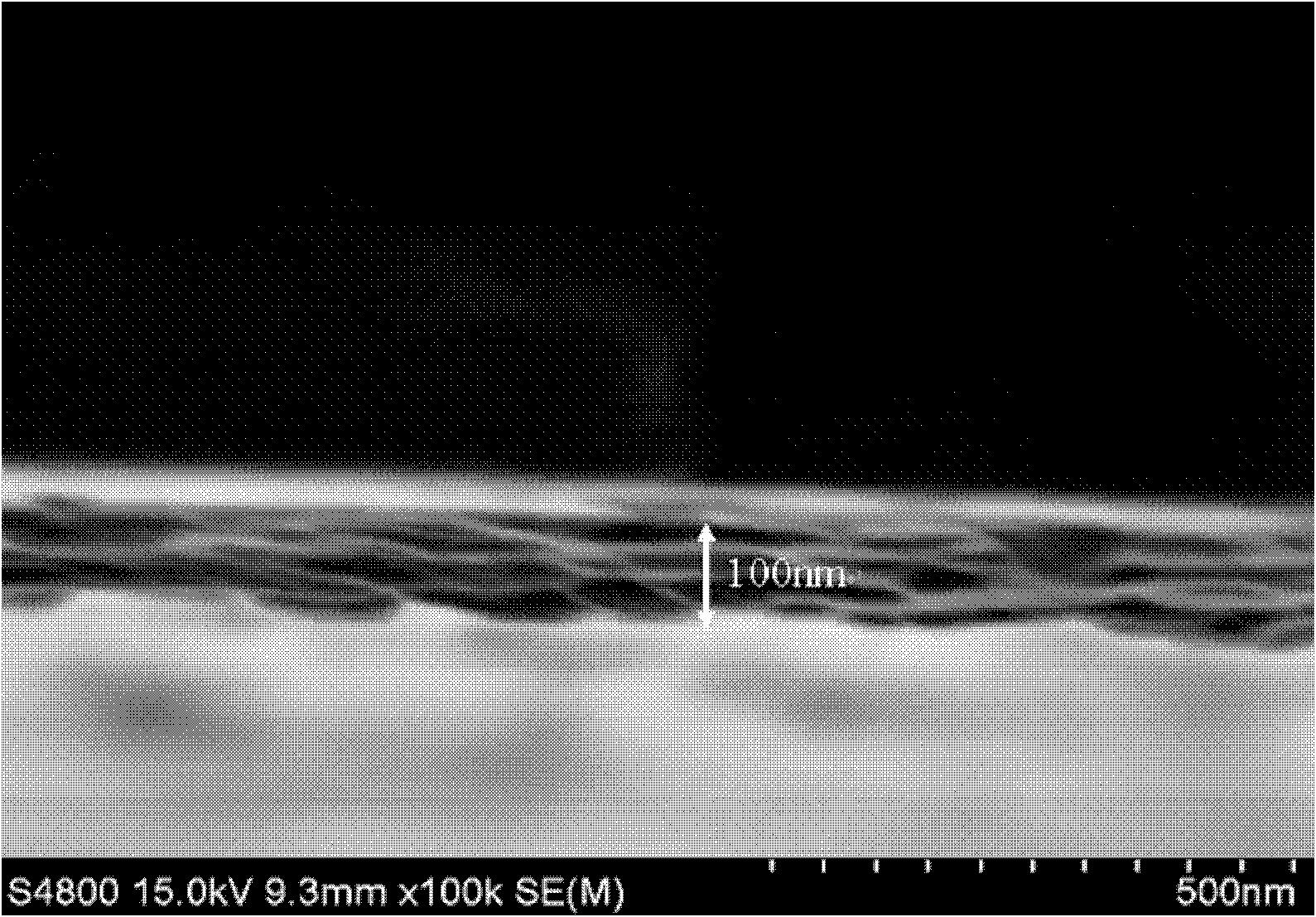

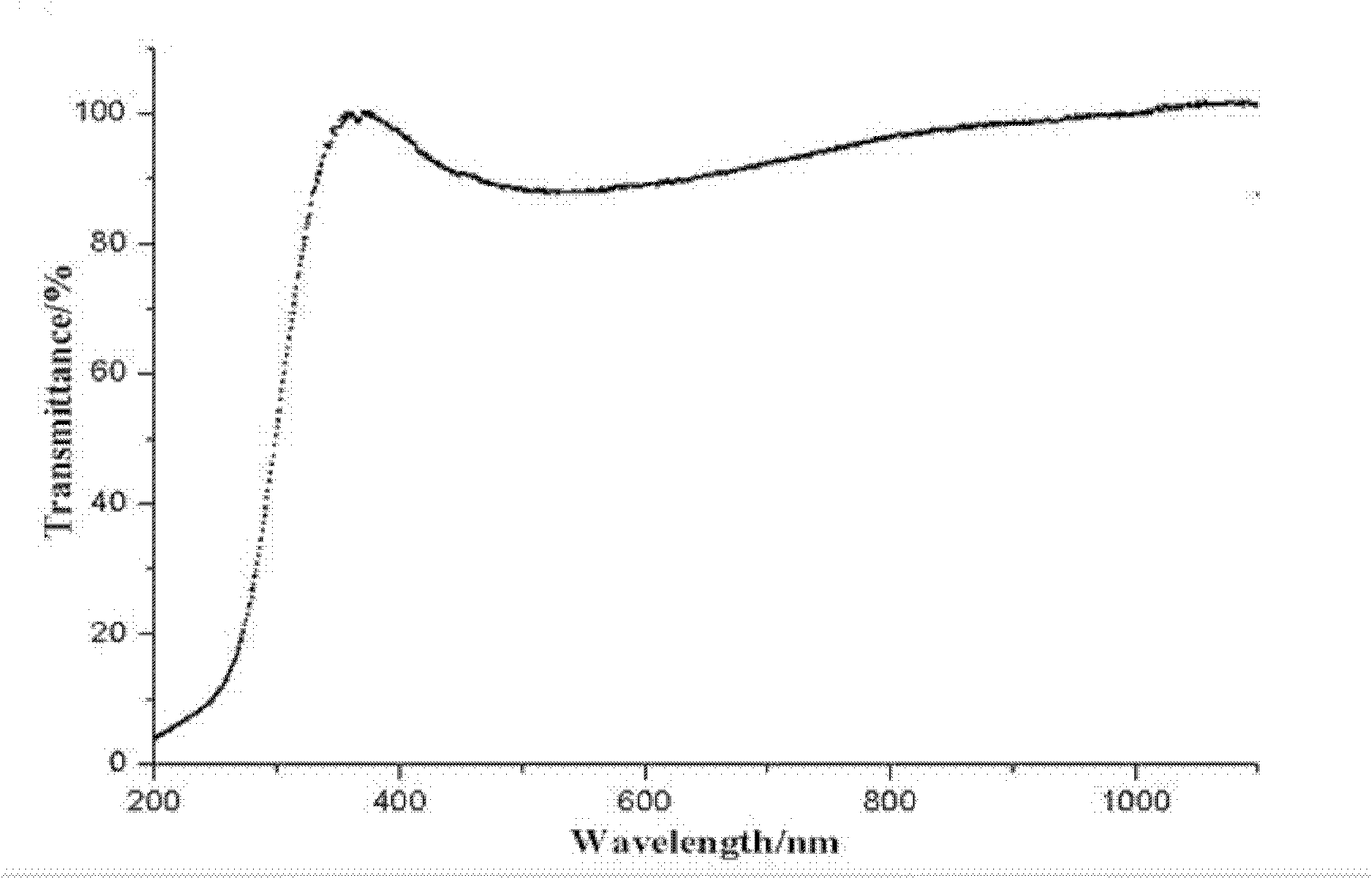

[0021] Each In with an average particle size of 0.5 μm 2 o 3 , SnO 2 , Ga 2 o 3 and MoO 3 The raw materials were weighed according to the mass ratio of 75:10:10:5, and then the raw materials and absolute ethanol were mixed according to the ratio of 2:3, placed on a ball mill for wet grinding for 12 hours, and then pre-synthesized at 600°C for 10 hours. After pre-synthesis, fully ball mill for 24 hours again, and the slurry is spray-dried and granulated to obtain a target material with an average particle size of 45 μm, which is molded by a powder tablet press preferably at a pressure of 5Mpa, and pressed into The green body obtained is sintered under normal pressure and air, and sintered according to the following process: keep the temperature at 600°C and 1100°C for 3 hours, sinter for 20 hours, keep the sintering temperature at 1300-1350°C during sintering, and then cool ...

Embodiment 2

[0042] (1) Preparation of gallium molybdenum co-doped indium tin oxide ceramic target material: using the method of Example 1 (1), In 2 o 3 , SnO 2 , Ga 2 o 3 and MoO 3 The mass ratio of the powder is 70:12:12:6.

[0043] The performance of gallium molybdenum co-doped indium tin oxide ceramic target was tested by the same method as in embodiment 1 (2). Table 1 shows the composition and physical properties of the ceramic targets.

[0044] (2) Preparation and evaluation of transparent gallium-molybdenum co-doped indium tin oxide conductive film: use the method of embodiment 1 (3), but what is sputtered is the ceramic target prepared in the above (1) step, thus A transparent conductive film is prepared.

[0045] The transparent conductive film was evaluated by a method similar to that in Example 1(4). The results are shown in Table 1.

Embodiment 3

[0047] (1) Preparation of gallium molybdenum co-doped indium tin oxide ceramic target material: using the method of Example 1 (1), In 2 o 3 , SnO 2 , Ga 2 o 3 and MoO 3 The mass ratio of the powder is 80:8:8:4.

[0048] The performance of the ceramic target was tested in the same manner as in Example 1 (2). Table 2 shows the composition and physical properties of the ceramic targets.

[0049] (2) Preparation and evaluation of gallium molybdenum co-doped indium tin oxide transparent conductive film: using the method of embodiment 1 (3), only the ceramic target prepared in the above (1) step was sputtered, thus A transparent conductive film is prepared.

[0050] The transparent conductive film was evaluated by a method similar to that of Example 1 (4). The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com