MgxZn1-xO electrically induced resistance change film and preparation method of asymmetrical structure heterojunction thereof

A mgxzn1-xo, asymmetric structure technology, applied in the field of preparation of MgxZn1-xO resistive film and its asymmetric structure heterojunction, can solve the problems of reducing market competitiveness, high unit cost, long period of time and so on , to achieve the effect of low cost, reducing internal stress and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

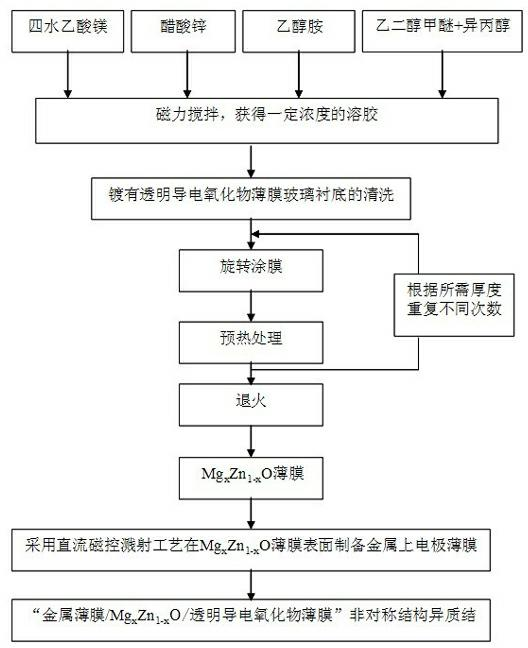

Method used

Image

Examples

Embodiment 1

[0045] (1) Use the glass coated with ITO transparent conductive film as the substrate, and perform surface treatment and cleaning on the glass substrate:

[0046] ① Soak in sodium hydroxide solution for 24 hours to remove the remaining attachments on the surface;

[0047] ② Ultrasonic cleaning with acetone for 10-15 minutes to remove organic matter on the substrate surface;

[0048] ③ Ultrasonic cleaning with ethanol for 8-15 minutes to remove hydrocarbons on the glass surface;

[0049] ④ Finally, ultrasonic cleaning with deionized water for 10 minutes to remove residual ethanol.

[0050] (2) Use the following raw materials (the purity of which is 99.99% of analytical purity) to prepare Mg 0.2 Zn 0.8 O-sol:

[0051] Zinc acetate (Zn(CH 3 COO) 2 2H 2 O) 52.68 grams

[0052] Magnesium acetate tetrahydrate (Mg(CH 3 COO) 2 4H 2 O) 12.867 grams

[0053] Ethanolamine 20.00ml

[0054] Ethylene glycol methyl ether 500ml

[0055] 500ml isopropyl alcohol

[0056] Among th...

Embodiment 2

[0070] (1) Use the glass coated with AZO transparent conductive film as the substrate, and perform surface treatment and cleaning on the glass substrate:

[0071] ① Soak in sodium hydroxide solution for 24 hours to remove the remaining attachments on the surface;

[0072] ② Ultrasonic cleaning with acetone for 10-15 minutes to remove organic matter on the substrate surface;

[0073] ③ Ultrasonic cleaning with ethanol for 8-15 minutes to remove hydrocarbons on the glass surface;

[0074] ④ Finally, ultrasonic cleaning with deionized water for 10 minutes to remove residual ethanol.

[0075] (2) Use the following raw materials (the purity of which is 99.99% of analytical purity) to prepare Mg 0.2 Zn 0.8 O-sol:

[0076] Zinc acetate (Zn(CH 3 COO) 2 2H 2 O) 87.80 grams

[0077] Magnesium acetate tetrahydrate (Mg(CH 3 COO) 2 4H 2 o) 21.445 grams

[0078] Ethanolamine 30.00ml

[0079] Ethylene glycol methyl ether 500ml

[0081] Among the...

Embodiment 3

[0091] (1) Use the glass coated with ITO transparent conductive film as the substrate, and perform surface treatment and cleaning on the glass substrate:

[0092] ① Soak in sodium hydroxide solution for 24 hours to remove the remaining attachments on the surface;

[0093] ② Ultrasonic cleaning with acetone for 10-15 minutes to remove organic matter on the substrate surface;

[0094] ③ Ultrashock with ethanol for 8-15 minutes to remove hydrocarbons on the glass surface;

[0095] ④ Finally, supershock with deionized water for 10 minutes to remove residual ethanol.

[0096] (2) Use the following raw materials (the purity of which is 99.99% of analytical purity) to prepare Mg 0.1 Zn 0.9 O-sol:

[0097] Zinc acetate (Zn(CH 3 COO) 2 2H 2 O) 59.265 grams

[0098] Magnesium acetate tetrahydrate (Mg(CH 3 COO) 2 4H 2 o) 6.4335 grams

[0099] Ethanolamine 20.00ml

[0100] Ethylene glycol methyl ether 500ml

[0101] 500ml isopropyl alcohol

[0102] Among them: (a) solute ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com