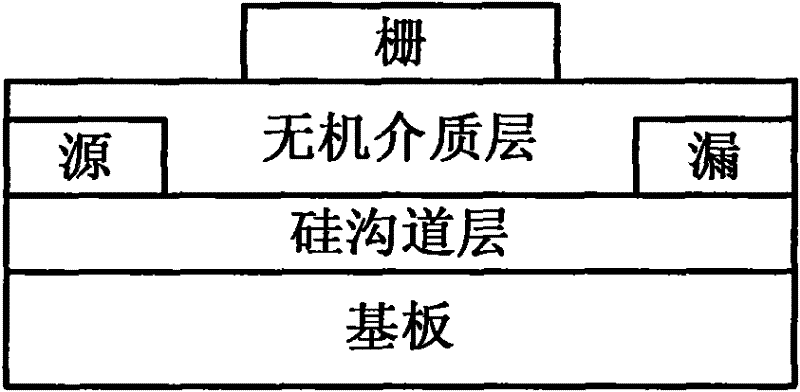

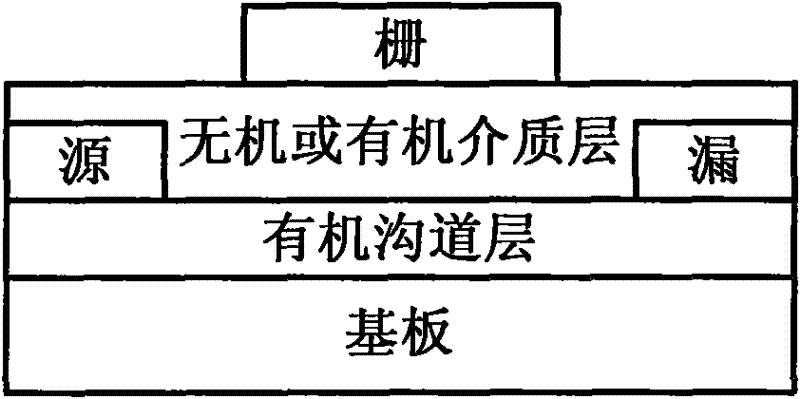

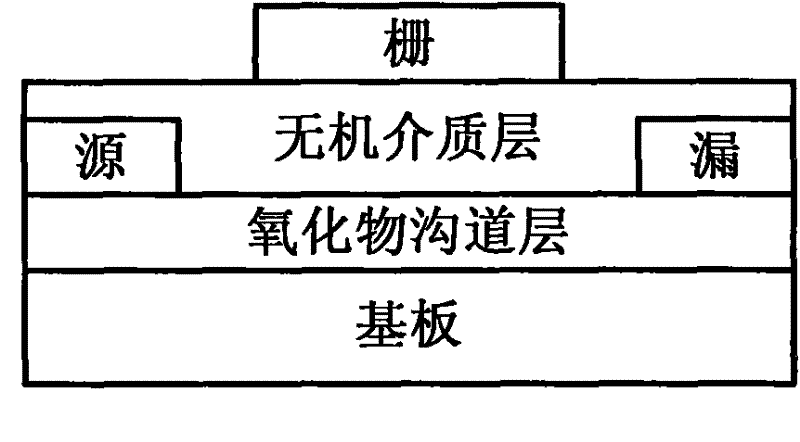

Mixed structure thin-film transistor taking oxide semiconductor as channel layer

An oxide semiconductor, thin film transistor technology, applied in transistors, semiconductor devices, electrical components, etc., can solve the problems of unsuitable flexible display screens, high dielectric layer process temperature, good electrical performance, easy low temperature and large area preparation, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0022] The indium-zinc alloy target (In:Zn=0.586:1 atomic ratio) is selected, and the reaction chamber is vacuumed to below 2×10-3Pa before a-IZO film deposition, and then the O 2 and Ar gas are passed into the reaction chamber in sequence, and the oxygen partial pressure in the reaction chamber is controlled to be 5.0×10 -2 Pa, the working pressure is 3.0×10 -1 Pa. The sputtering current and the sputtering voltage were adjusted to 120mA and 300V respectively, and the sputtering time was 10 minutes to form a thin film on a common glass sheet. The thickness of the film is about 110nm, and the resistivity is greater than 1×10 4 Ω·cm, the average transmittance of visible light is greater than 82%.

[0023] 80nm aluminum films were prepared as source-drain electrodes by reactive magnetron sputtering with aluminum oxide masks with aspect ratios of 500μm / 100μm and 400μm / 40μm. The sputtering current was 100mA and the sputtering voltage was 350V.

[0024] A 20 mg / ml polytetravinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com