Transparent semiconductor film diode and preparing method thereof

A thin-film diode and transparent thin-film technology, applied in the field of transparent semiconductor thin-film diodes and their preparation, can solve the problems that transparent electronic devices are in the laboratory stage and not commercialized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

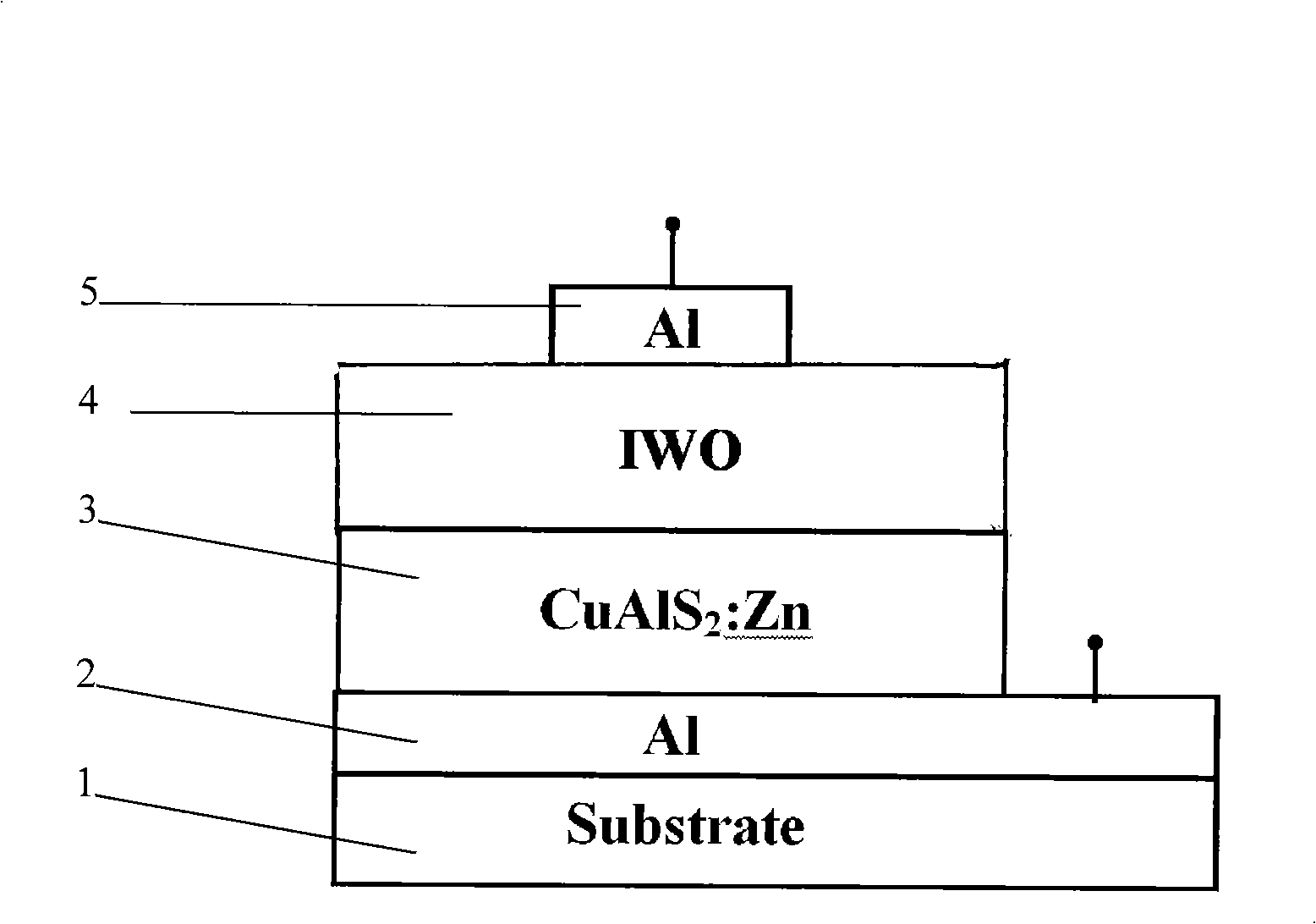

Image

Examples

Embodiment 1

[0018] Embodiment 1, the first step, using the pulsed plasma deposition method to deposit p-type conductive CuAl on a common glass substrate 0.90 Zn 0.10 S 2 film. Preparation of CuAl according to traditional ceramic target preparation method 0.90 Zn 0.10 S 2 Circular target with a target diameter of 15 mm. The distance between the target surface and the quartz tube was fixed at 4 mm. The inner diameter of the quartz catheter is 2mm. The substrate is a common glass slide, which is ultrasonically cleaned with deionized water, acetone and alcohol for 20 minutes each. The background pressure of the vacuum chamber before film deposition was 2.0×10 -4 Pa.

[0019] Use the gas flow meter of Bronkhorst Company to control the flow of Ar so that the pressure of the working gas is 2.4Pa, the temperature of the substrate is kept at room temperature, and the voltage and current of the ablation source are set to -18.0KV and 4.2 mA, the pulse electron beam repetition frequency is ...

Embodiment 2

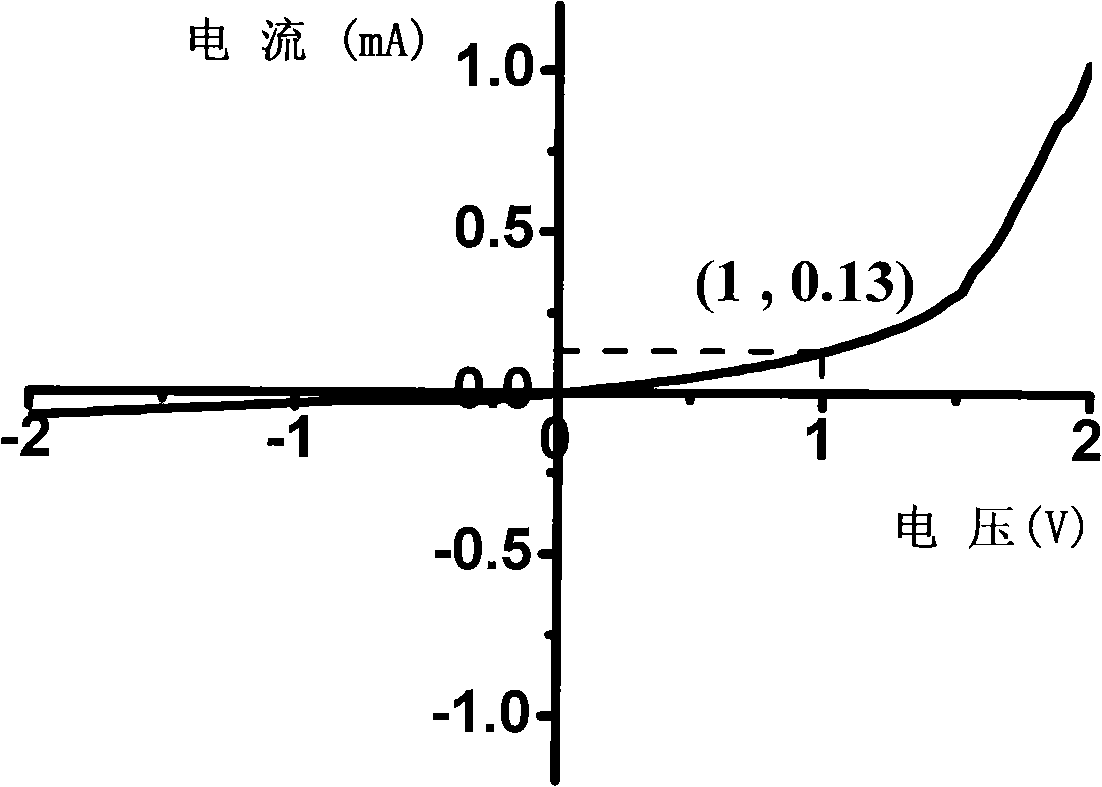

[0021] Embodiment 2, the same step and method as embodiment 1, only in the preparation of CuZn 0.1 al 0.9 S 2 Change the preparation parameters when thin film: the ablation gas pressure is 2.4Pa, the substrate temperature is still at room temperature, the ablation source voltage and current are set to -18.0KV and 4.2mA respectively in the power supply, and the pulse electron beam repetition frequency is 2.0Hz. The film deposition time is 60 minutes, and the film thickness is 70 nm.

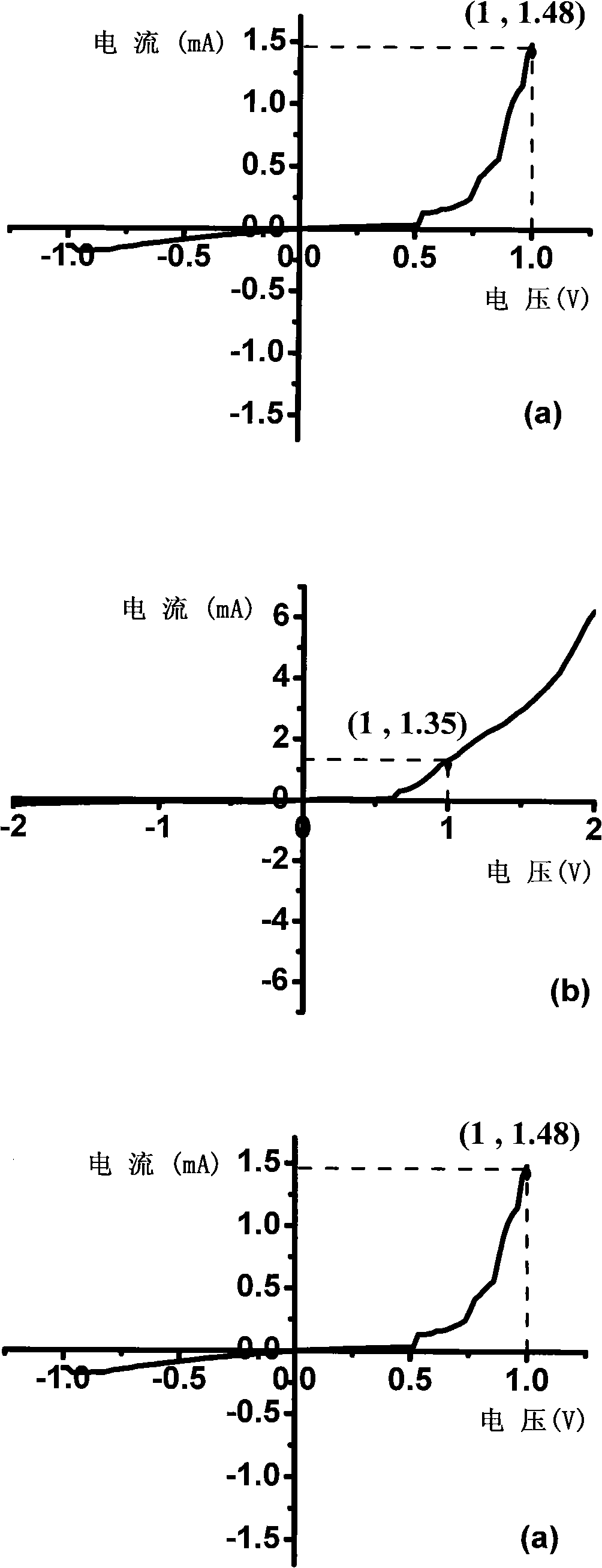

[0022] The thickness of each layer of film was measured with a Kosaka ET3000 surface profiler. The sheet resistance of each film at room temperature was measured using a BD-90 four-probe instrument. The Seebeck coefficient and Hall coefficient of the film were measured at room temperature using a Hall test system (Accent HL5500 Hall System). The transmission spectrum of the transparent device in the visible light range was measured with a Shimadzu UV2450 ultraviolet / visible spectrophotometer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com