Conductive transparent copper-doped nickel oxide film and preparation method thereof

A conductive transparent nickel oxide technology, applied in the field of transparent electronics research, can solve the problems of restricting the application of TOS materials and the inability to synthesize transparent oxide pn junctions, etc., and achieve the effect of low equipment price, low price and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

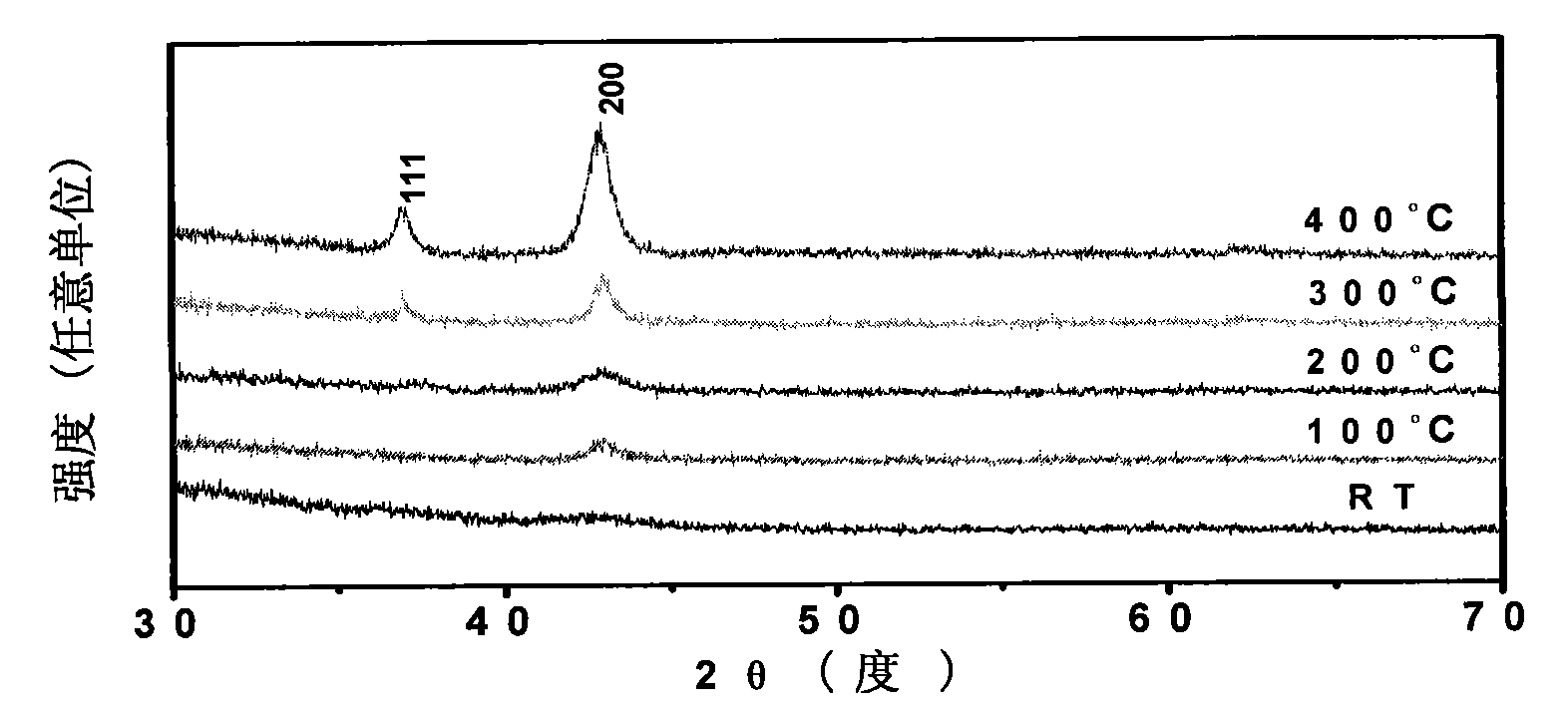

[0017] According to stoichiometric ratio Ni 0.9 Cu 0.1 O Prepare a circular ceramic target with a diameter of 23.4mm. Film preparation by PPD: the substrate is a common glass slide, which has been ultrasonically cleaned by deionized water, acetone and alcohol for 20 minutes each; the distance between the target surface and the quartz tube is fixed at 4mm, and the distance between the target surface and the substrate is 25mm; the substrate temperature changes The range is from room temperature to 400°C; set O 2 For the working air pressure, use Bronkhorst’s mass flowmeter to control its flow, so that the working air pressure is 3.0Pa; the HCL 140-20000 high-voltage DC power output source sets the working voltage and current to -18.0kV and 3.0mA respectively; the pulsed electron beam The frequency is 2.0 Hz; the film deposition time is about 45 minutes.

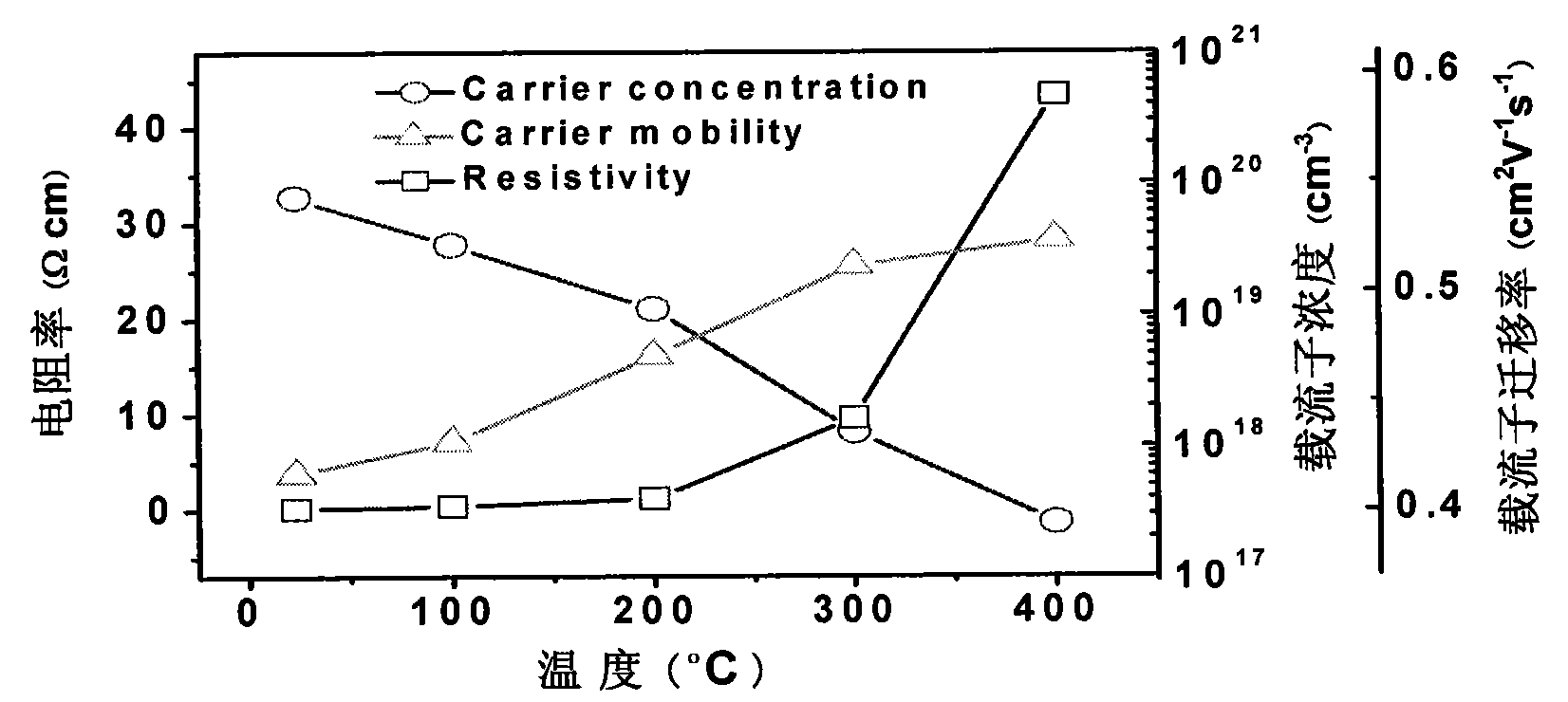

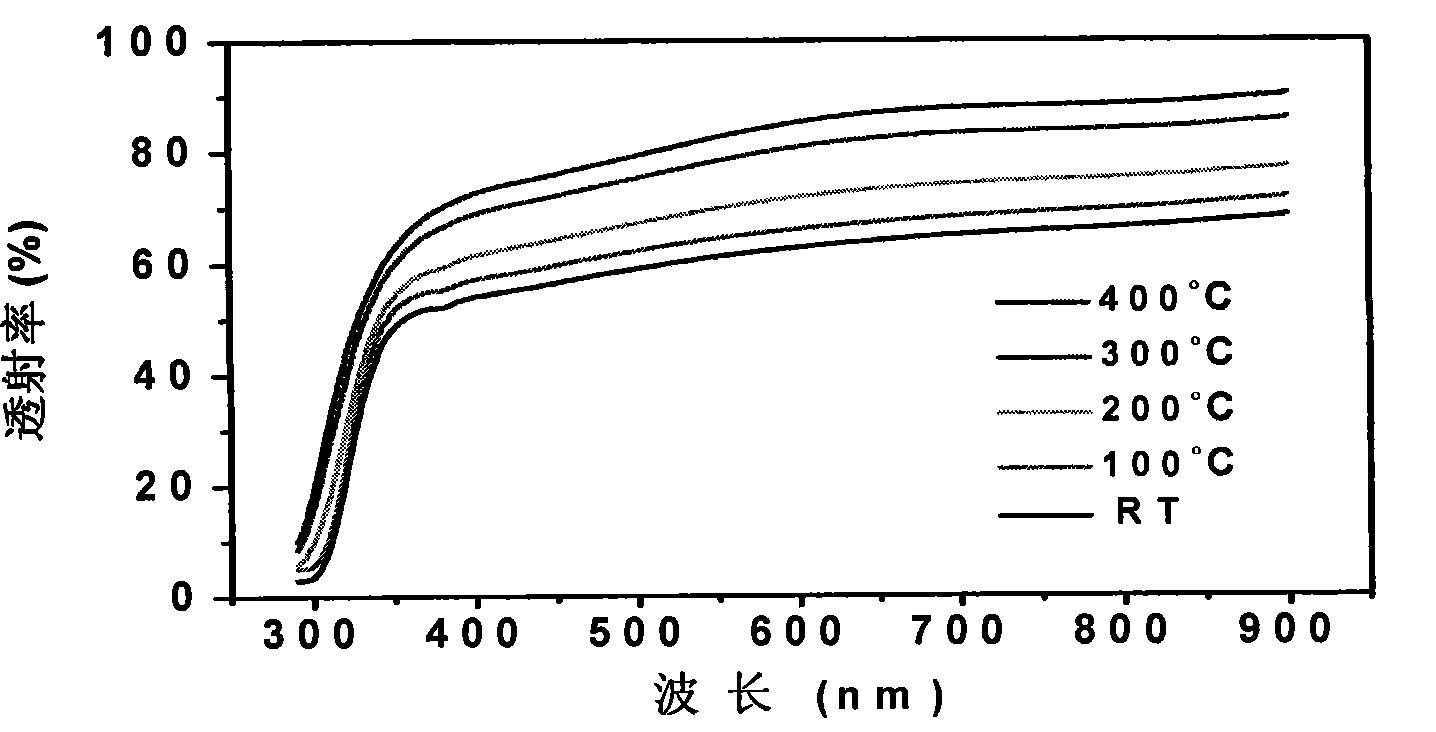

[0018] The experimental results are shown in the attached figure, figure 2 In, Ni prepared at room temperature 0.9 Cu ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com