ANSYS finite element platform-based prediction method for induction quenching hardening layer depth

A technology of hardened layer depth and induction hardening, applied in special data processing applications, instruments, electrical digital data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

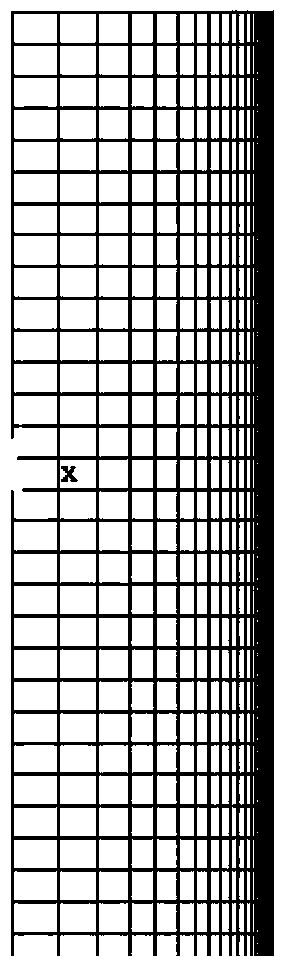

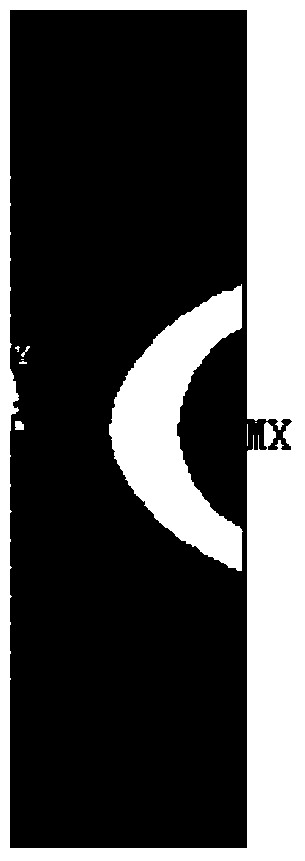

[0024] Such as Figure 1~4 As shown, using ANSYS finite element analysis software to analyze the temperature field of the induction heating in the induction hardening of the S45C steel optical shaft, including the following steps:

[0025] (a) According to the technical requirements of the workpiece, determine the actual working environment during induction hardening: Among them, it is necessary to determine the induction heating conditions: induction heating frequency f = 186kHz, heating time t = 4.2s, current density Js = 700 × 10 6 A / m 2 ;The workpiece is an optical axis with a diameter of Φ16mm and a length of 30mm; the inner diameter of the induction coil is Φ20mm and the height is 8mm;

[0026] (b) One-dimensional modeling of 1 / 2 of the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com