Electroplating copper clad aluminum conductor

A technology of electroplating copper and aluminum cladding, which is applied in the direction of metal/alloy conductors, etc., can solve the problems that the temperature rise of copper wires cannot be monitored, reduce market competitiveness, increase production costs, etc., achieve good product quality, reduce line loss, and strengthen The effect of online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

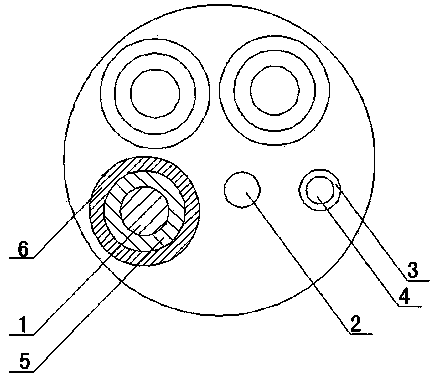

Embodiment 1

[0011] An electroplated copper-clad aluminum wire, which has a circular aluminum-magnesium body 1, and the wire composed of a plurality of circular aluminum-magnesium bodies 1 is a circular base core, and a piece engraved with The grating fiber 2 of the temperature measuring grating and a soft copper tube of the cooling channel. A grating temperature measuring point is formed on the grating optical fiber 2 every predetermined distance. The soft copper tube of the cooling channel is a soft copper tube 4 with an insulating film wrapping layer 3 having the same length as the round aluminum-magnesium body 1 . The outer layer of the circular aluminum-magnesium body 1 is provided with a tin layer 5 , and a copper plating solution 6 is electroplated between the circular aluminum-magnesium body 1 and the tin layer 5 . The formula of the copper plating solution 6 is: 40-50 g / L of one of copper nitrates, 120-150 g / L of hydroxybutylene diphosphonic acid, 2-5 g / L of methylaminodimethylid...

Embodiment 2

[0013] An electroplated copper-clad aluminum wire, which has a circular aluminum-magnesium body 1, and the wire composed of a plurality of circular aluminum-magnesium bodies 1 is a circular base core, and a piece engraved with The grating fiber 2 of the temperature measuring grating and a soft copper tube of the cooling channel. A grating temperature measuring point is formed on the grating optical fiber 2 every predetermined distance. The soft copper tube of the cooling channel is a soft copper tube 4 with an insulating film wrapping layer 3 having the same length as the round aluminum-magnesium body 1 . The outer layer of the circular aluminum-magnesium body 1 is provided with a tin layer 5 , and a copper plating solution 6 is electroplated between the circular aluminum-magnesium body 1 and the tin layer 5 . The formula of the copper plating solution 6 is: 30-40 g / L of copper nitrate, 100-130 g / L of hydroxybutylene diphosphonic acid, 1-4 g / L of methylammonium dimethylene ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com