A Correction Method Based on Six-Pulse Algorithm to Realize the Installation Position Deviation of Hall Sensor

A technology of Hall sensor and installation position, applied in the direction of controlling electromechanical transmission, controlling electromechanical brake, controlling generator, etc., can solve the problems of ineffective manual error correction, bottleneck of large-scale promotion and use, and increase of input cost, etc. Improve the correction effect, avoid human installation errors, and reduce the effect of input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Attached below Figure 1-Figure 7 The present invention is further illustrated with specific examples.

[0037] The steps to implement the correction method for the installation position deviation of the Hall sensor are as follows:

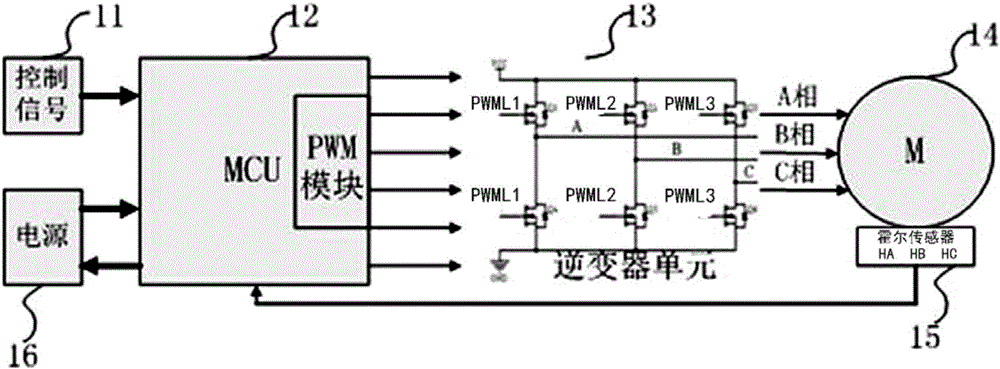

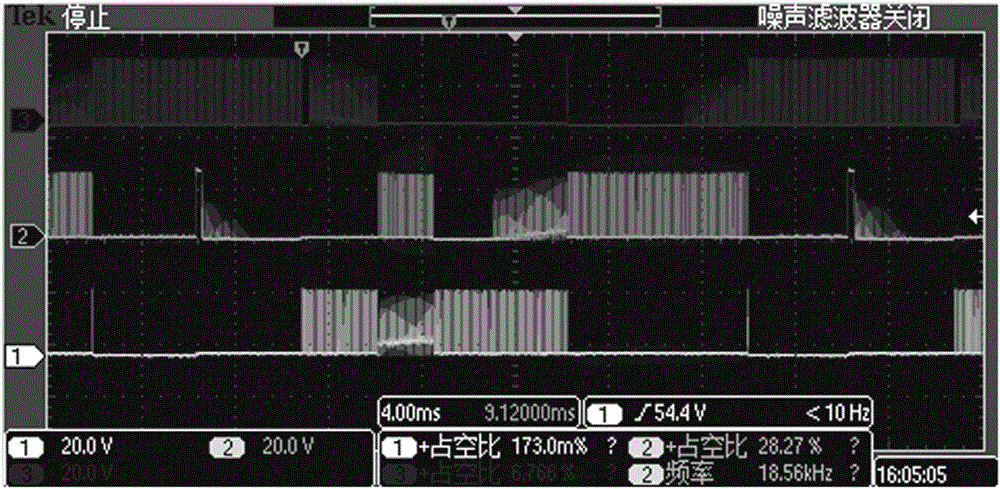

[0038] (1). If figure 1 As shown, the control signal 11 is input into the MCU module 12, the power supply 16 supplies power for the system, and the signal output by the MCU module realizes the control of the motor 14 through the inversion of the inverter unit; the output duty of the PWM module in the MCU module 12 is set Ratio D=10%, execution time Ti=100ms;

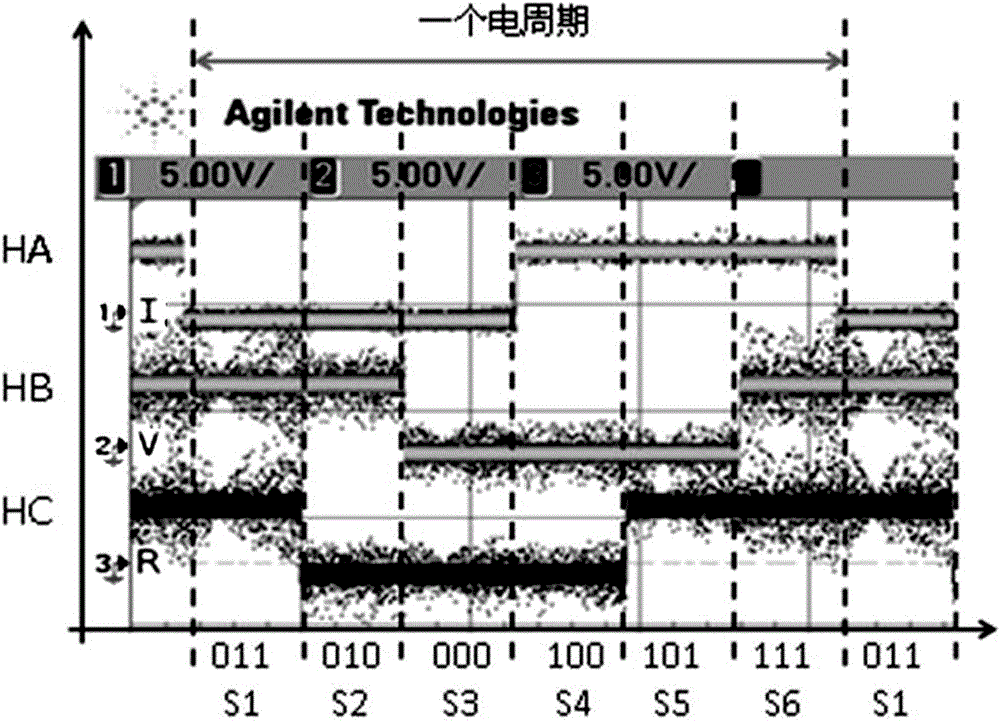

[0039] (2). Set the relative installation electrical angle α of the three Hall sensors HA, HB, and HC in the Hall sensor group 15, α=60° (or 120°), and determine the pole pair number N of the controlled object motor = 5;

[0040] (3). Fix the three Hall sensors HA, HB, and HC according to the mechanical angle of α / N=60° / 5=12°, and then fix the three Hall sensors fixed on the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com