Refining method and device for low-grade brown rice

A low-grade, fine-grinding technology, applied in the fields of grain finishing, grain degerming, agriculture, etc., can solve the problems of many defective products and low yield, and achieve the effect of reducing the generation of broken rice, lightening the load, and improving the luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The refining test was carried out with the brown rice of short-grain varieties produced in China.

[0052] As the raw material variety, "Kongyu 9031" of the "Kongyu 131" series, a Japanese short-grain seed produced in 2009, was used. Whiteness is used as a reference for fineness. The whiteness was measured by the brown rice and polished rice whiteness meter C-300 manufactured by KETT Scientific Research Institute of Japan.

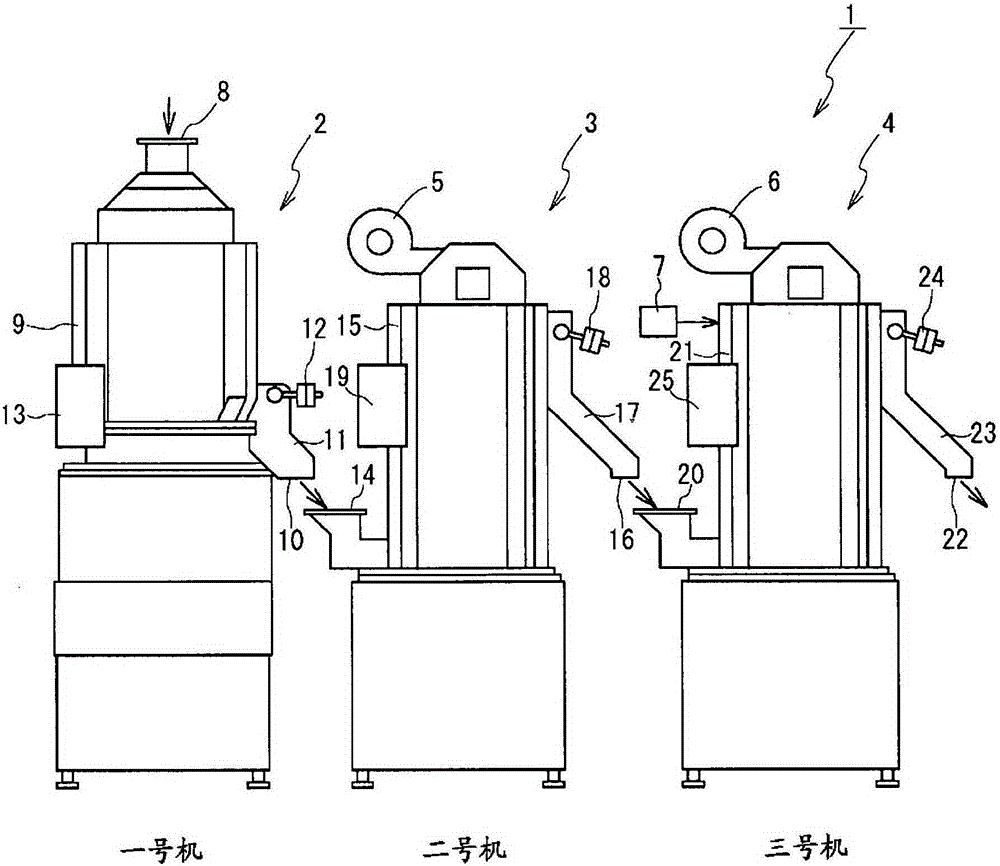

[0053] Initially, the refining test was carried out with a triple-tandem refining apparatus equipped with standard stirring rolls and a rice-grinding wire mesh, which did not have the features of the present invention. The results are shown in Table 1 below.

[0054] [Table 1]

[0055] Flow 6ton / Hr

[0056]

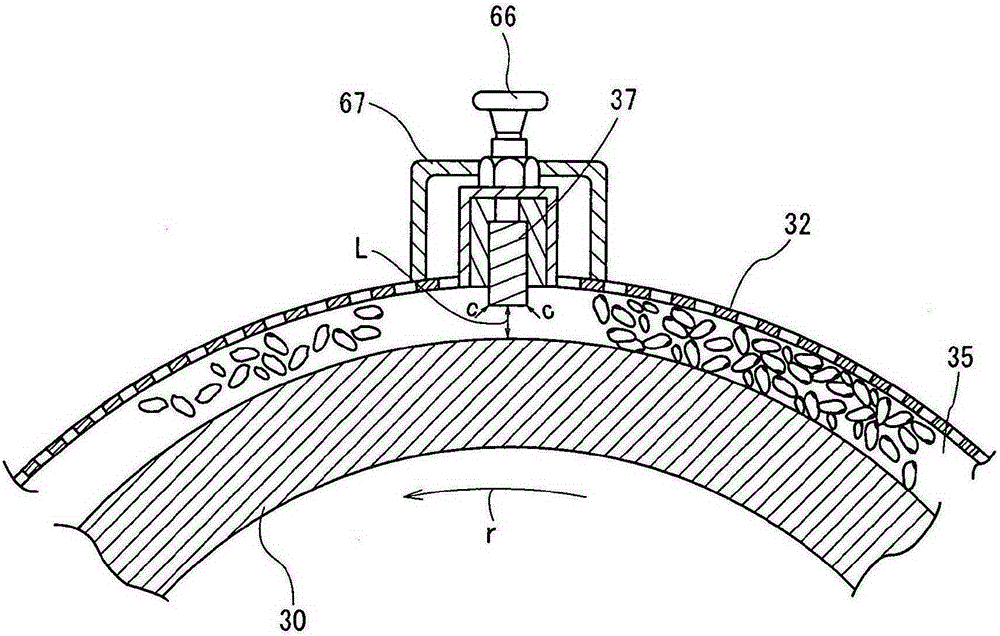

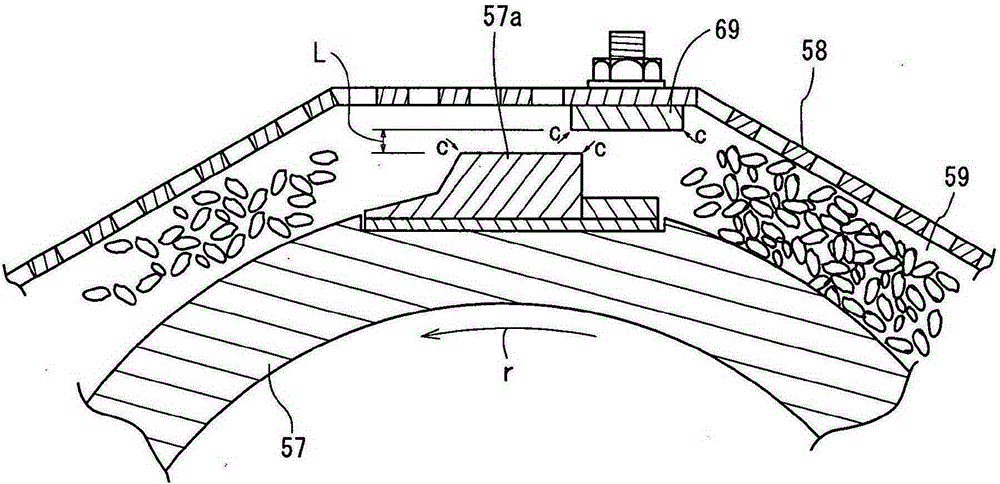

[0057] Next, a refinement test was carried out by using the elongated resistance body 37, the resistance rod 69, and the stirring rod 57a of the present invention, and the adjustment of the gap was completed by the three-series re...

Embodiment 2

[0070] The refining test was carried out with brown rice of short-grain varieties produced in Korea.

[0071] As the raw material variety, "No. 5", a short-grain variety close to Japan produced in 2009, was used. The mixing rate of cracked grains of raw brown rice was 22%, and the mixing rate of immature grains was 10%. As a benchmark for fineness, whiteness is used. The whiteness was measured by a brown rice / milled rice whiteness meter C-300 manufactured by KETT Scientific Research Institute of Japan.

[0072] Initially, refining tests were conducted with a triple-tandem refining apparatus equipped with standard stirring rolls and a rice-grinding wire mesh, which did not have the features of the present invention. The results are shown in Table 4 below.

[0073] [Table 4]

[0074] Flow 6.3ton / Hr

[0075]

raw brown rice

No. 1 machine

machine 2

Unit 3

BaiDu

20.7

21.9

35.3

40.6

Moisture (w.b%)

15.5

15.0

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com