Durable solar mirror films

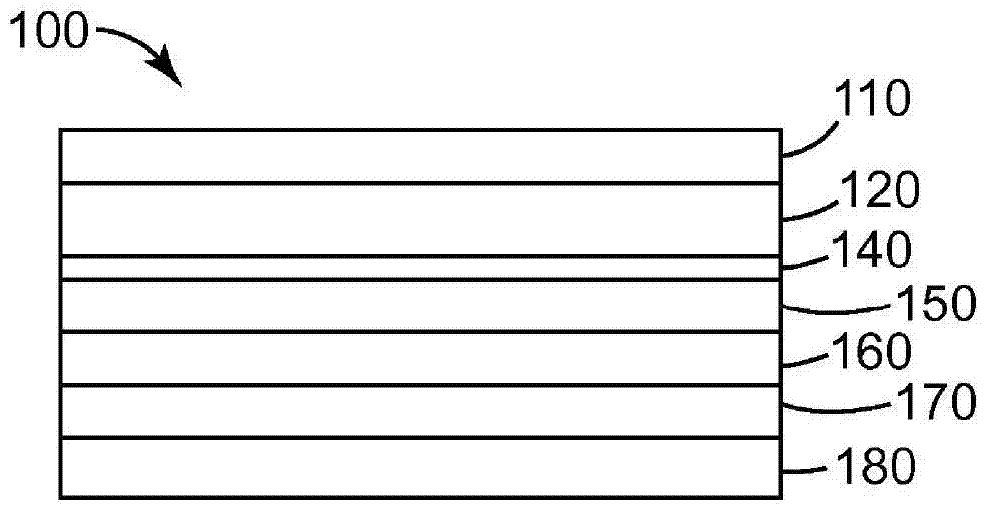

A specular reflective film and solar energy technology, which is applied in solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problem that the working temperature is not so high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0086] testing method

[0087] Neutral salt spray test

[0088] Except that the results are reported as % reflective area after various times in salt spray or simply as visually observed failures while in salt spray, according to ISO 9227:2006 "Corrosion tests in artificial atmospheres - Salt spray test ( Corrosion tests in artificial atmospheres--Salt spray tests)" to evaluate the corrosion of comparative examples and examples. Visual observation failure means the first visual indication of corrosion when the sample is in the salt spray.

[0089] reflective area percentage

[0090] The reflective area of each sample was taken as the surface area of the laminated sample that did not show any signs of discoloration due to corrosion or delamination. This area is then reported as a percentage of the original reflective surface area of the sample. The initial reflection area of the samples was taken as the full surface area of the control samples and the area w...

example 1

[0097] A reflective mirror reflective film comprising a polymer layer and a metallized layer (under the trade designation "SOLAR MIRROR FILM SMF-1100 (solar mirror reflective film SMF-1100)" was obtained from 3M Company, St. Paul, Minnesota. , MN)) were laminated to an aluminum-coated substrate having a thickness of approximately 0.02 inches (0.05 cm) after removal of the pressure sensitive adhesive liner on the metallized side. The aluminum substrate was then cut into 10.2 cm x 10.2 cm (4 in x 4 in) samples using a shear cutter. Remove the pre-separation mask.

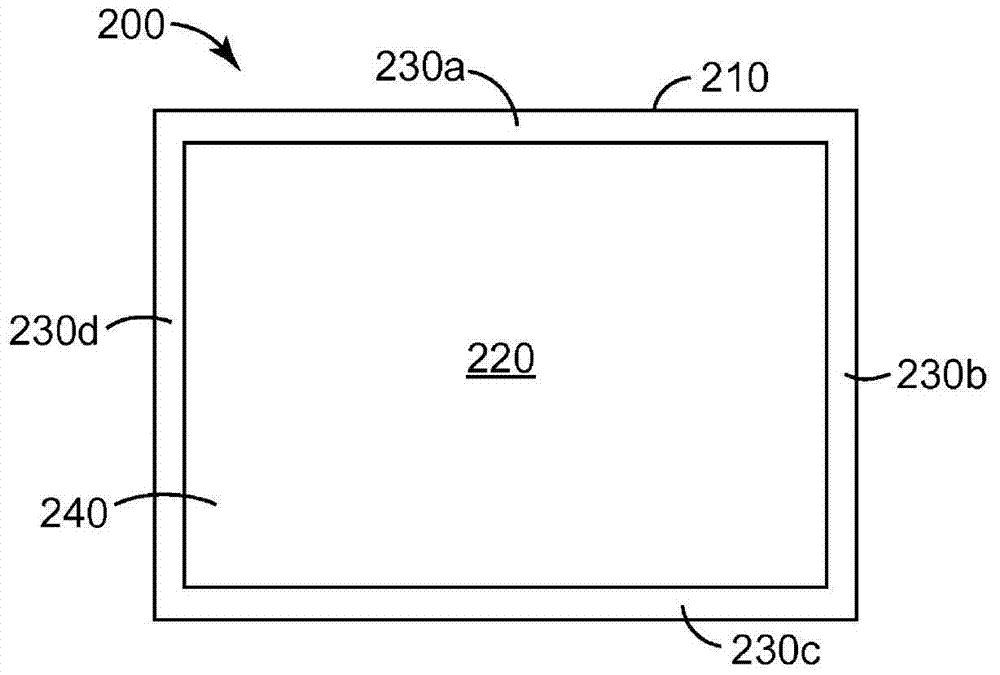

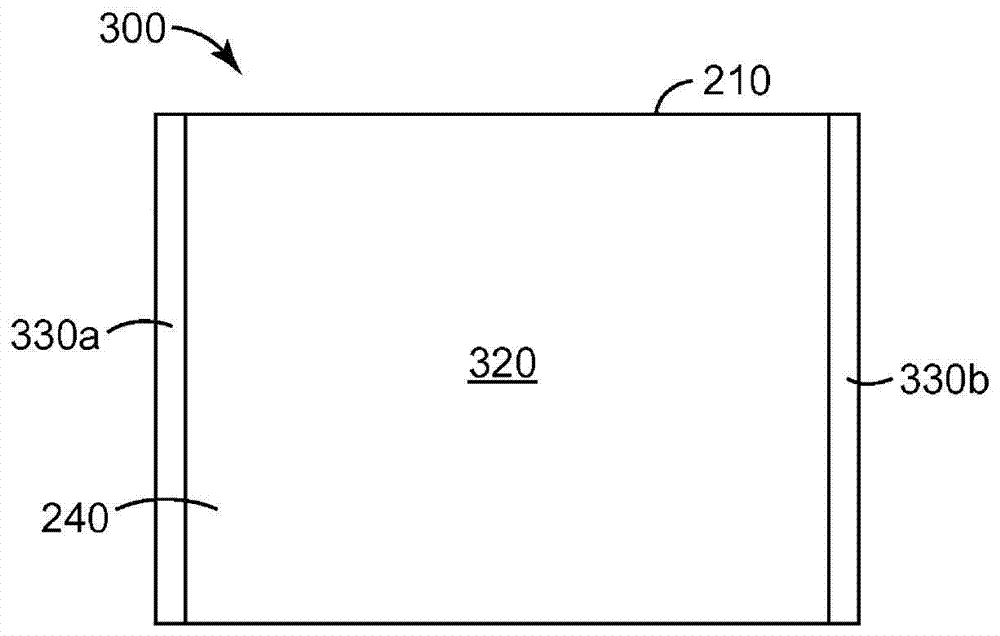

[0098] Ultrasonic energy was used to weld the reflective specularly reflective film along its edges as follows. The following ultrasonic welder was used: a frequency of 20 kHz, a power output of 4 kW, with a 3 inch (7.62 cm) cylinder (available from Emerson Industrial Automation, St. Louis, MO) "BRANSON model" 2000X"), a commercially available 1.5 gain titanium booster made by the Branson Company, and a titanium rod...

example 2

[0101] Weld samples were prepared as described in Example 1, except that a pressure of 280 kPa (40 lbf) was used. The samples were tested according to the above "Neutral Salt Spray Test" and the results are provided in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com