No-tillage field-returning seeder for straws

A seeder and straw technology, applied in sowing, harvester, crop processor and other directions, can solve the problems of increasing investment, freezing and dying of winter wheat, destroying the structure of pellets, etc., so as to save farming costs, increase grain yield, and suppress weeds. effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

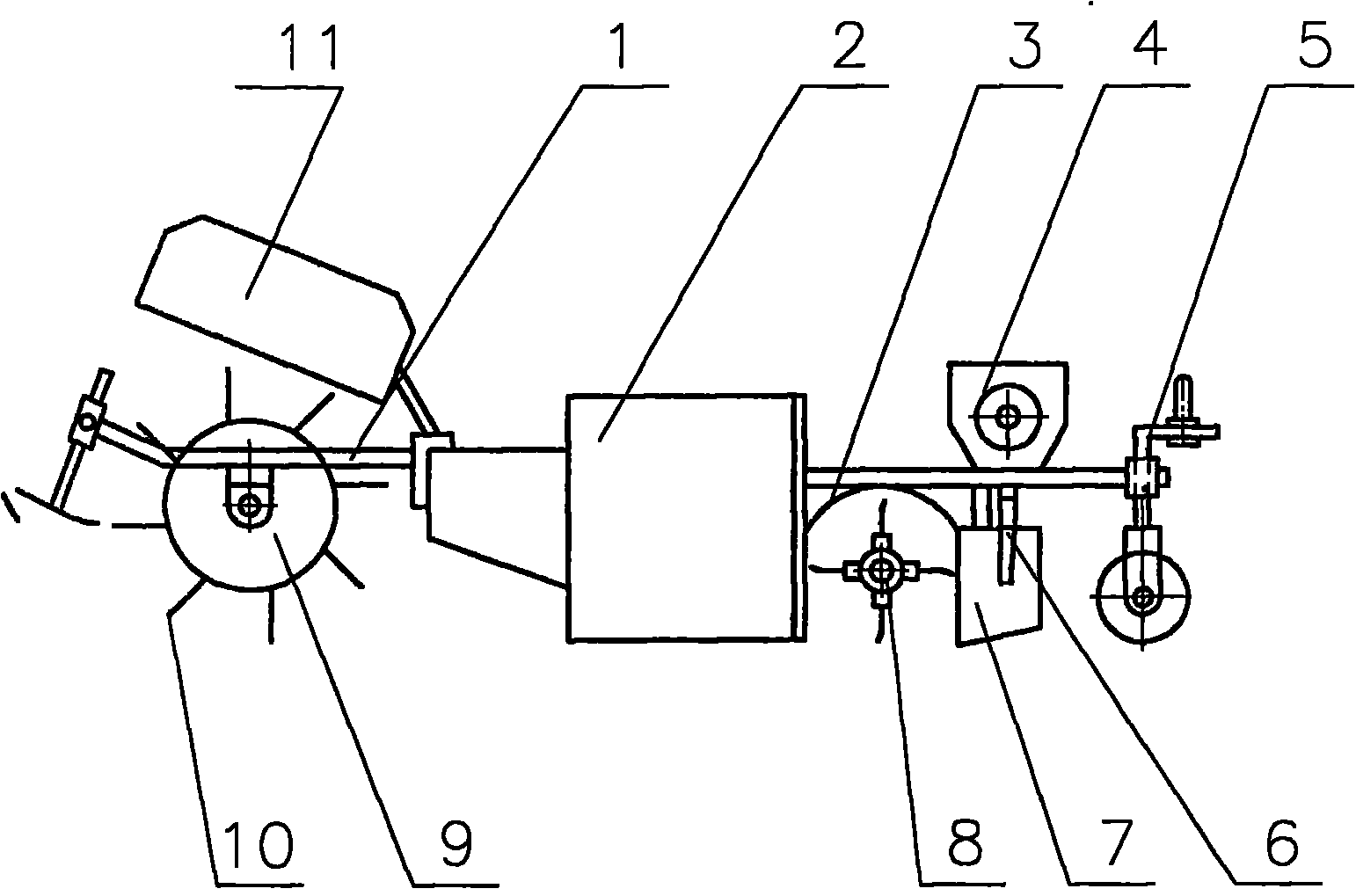

[0012] The technical scheme of the present invention will be further explained below with the accompanying drawings and embodiments

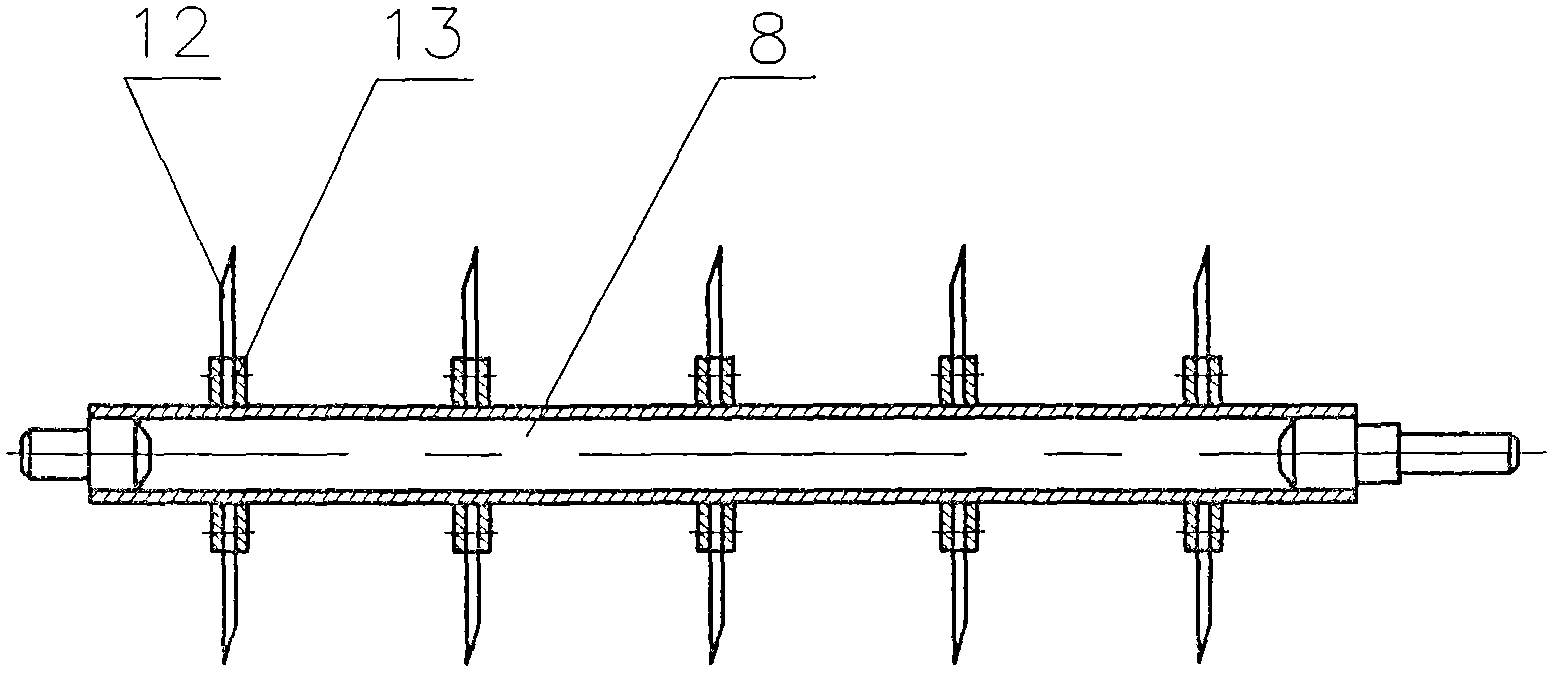

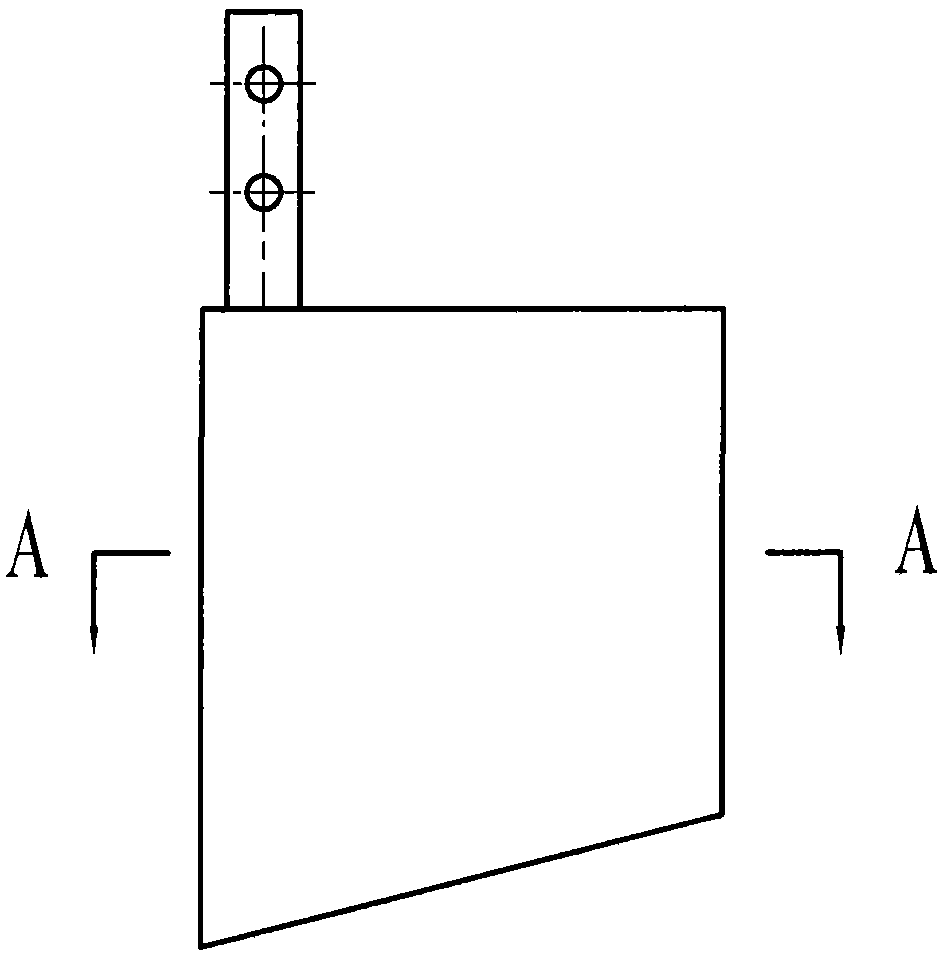

[0013] Such as figure 1 It is shown that the grass cutting device 3 and the seeding device 4 are installed at the rear of the walking tractor 2, and the opener 1 is installed at the front of the walking tractor 2. Before sowing, remove the cutter head 9 on the opener 1 and sowing When the grass cutting blade 12 rotates with the grass cutter shaft 8 at a high speed to cut the grass, and throw the grass and part of the soil along the V-shaped retaining plate 7 to the rear of both sides of the sowing nozzle 6. The seeding nozzle 6 is on the V-shaped retaining plate 7. The seeds are planted on the surface of the ground, and the hand-held drag 2 is used to sow 5 rows per walk, the row spacing is 23 cm, and the total sowing width is 1.2 meters. The single-side throwing width of the opener 1 is 1.5 meters, so every time Two sowing widths open a ditch, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com