Multifunctional machine

A multifunctional machine and accessory technology, applied in the direction of portable mobile devices, metal processing machinery parts, portable impact tools, etc., can solve problems such as human health hazards and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

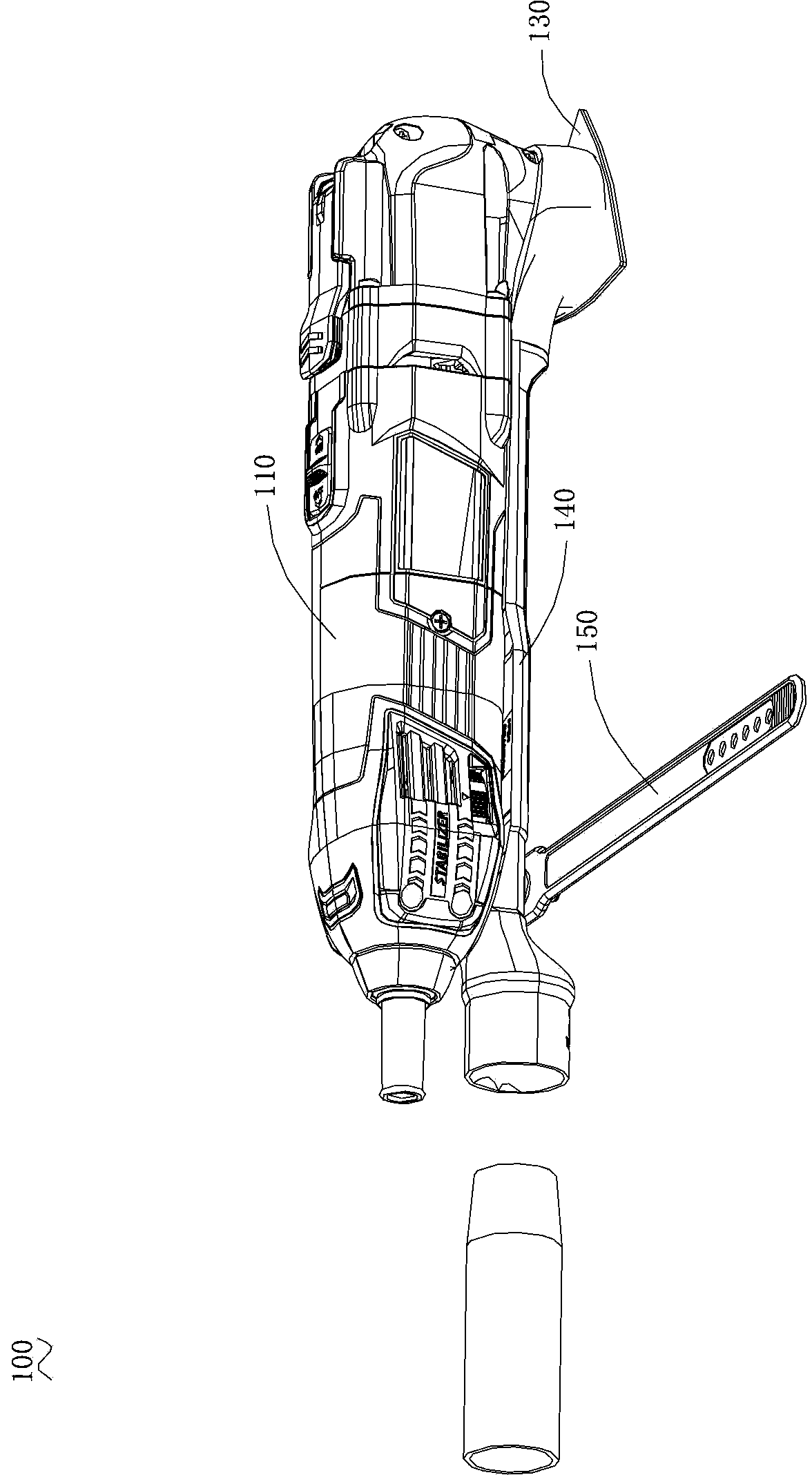

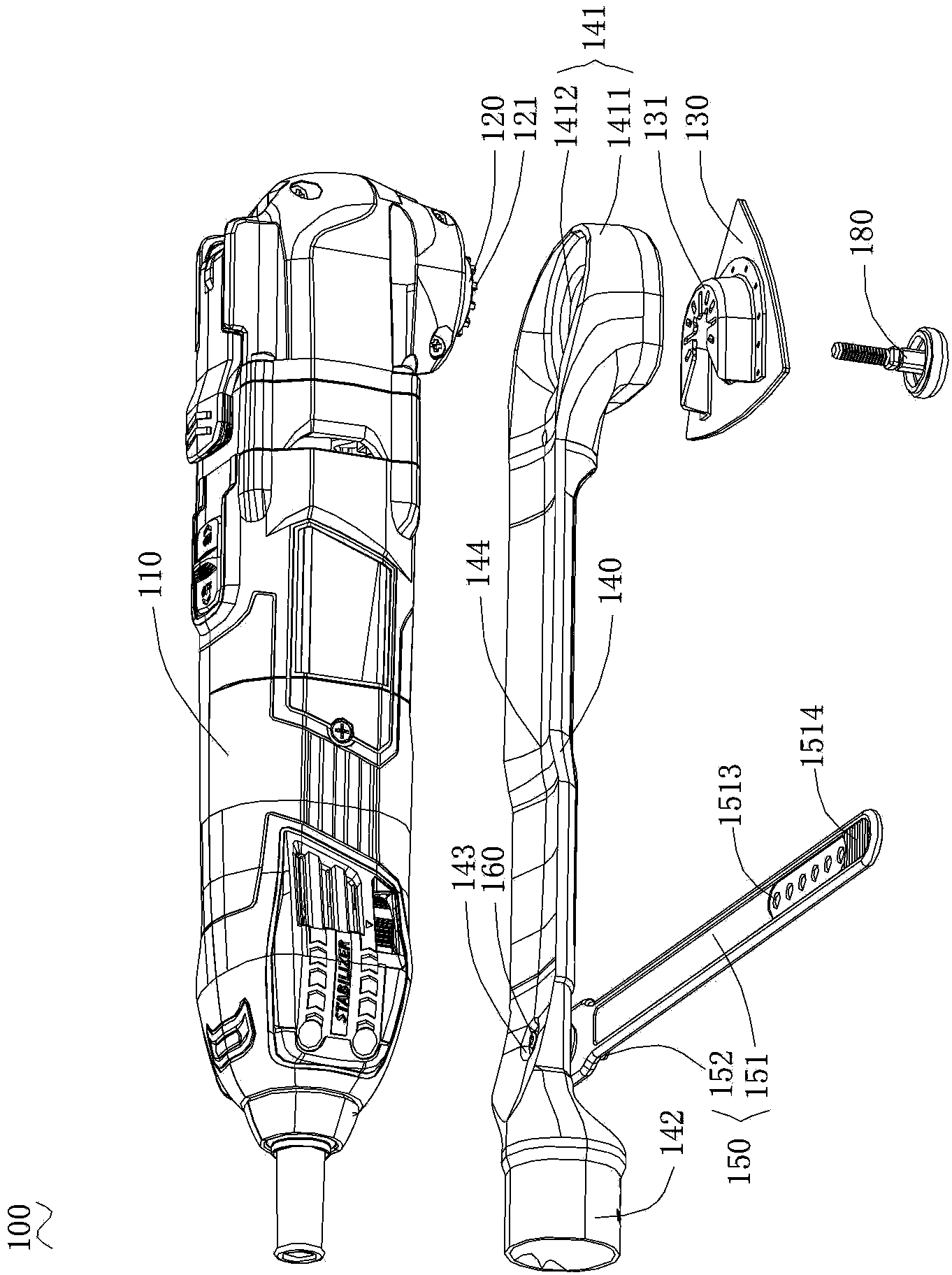

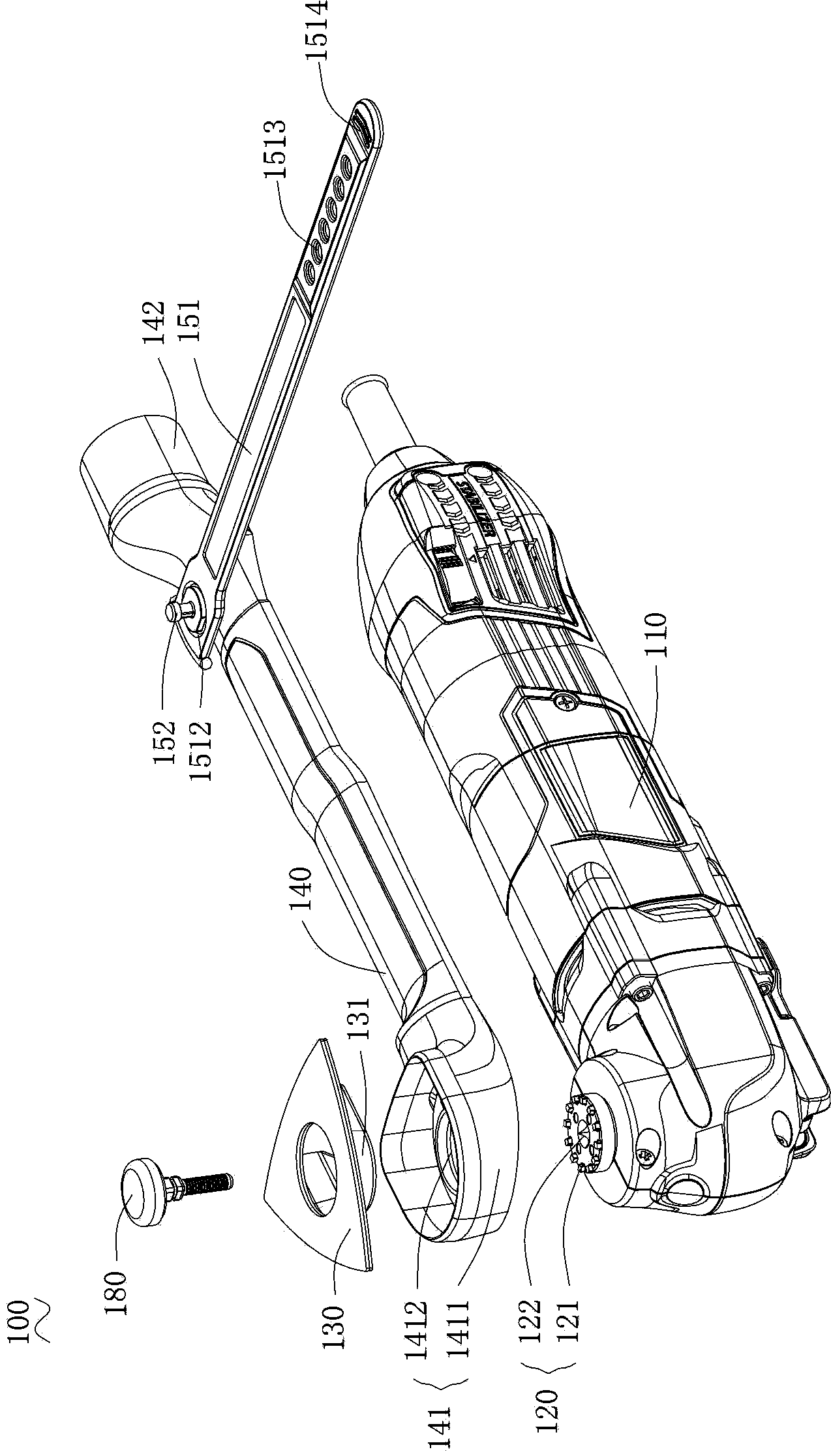

[0038] Please refer to Figure 1 to Figure 3 , this embodiment discloses a multifunctional machine 100 , which includes a housing 110 , an output shaft 120 extending from the housing 110 , and a working head attachment 130 installed on the output shaft 120 . Wherein, the output shaft 120 can swing back and forth around its own axis. The working head attachment 130 has a mounting portion 131 that can be connected to the output shaft 120 , and the output shaft 120 has a fixing portion 121 that can match the mounting portion 131 . Through the fixed connection of the mounting part 131 and the fixing part 121 , the working head attachment 130 can realize various operation functions such as sawing, cutting, grinding and scraping under the drive of the output shaft 120 . In order to ensure that the working head attachment 130 can be more stably fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com