Clamping mechanism with overturn function and method for overturning and translating workpiece

A technology of clamping mechanism and function, applied in the field of clamping mechanism, can solve the problems of increasing the complexity of mechanical gripper equipment cost control circuit design, etc., and achieve the effect of improving market competitiveness and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

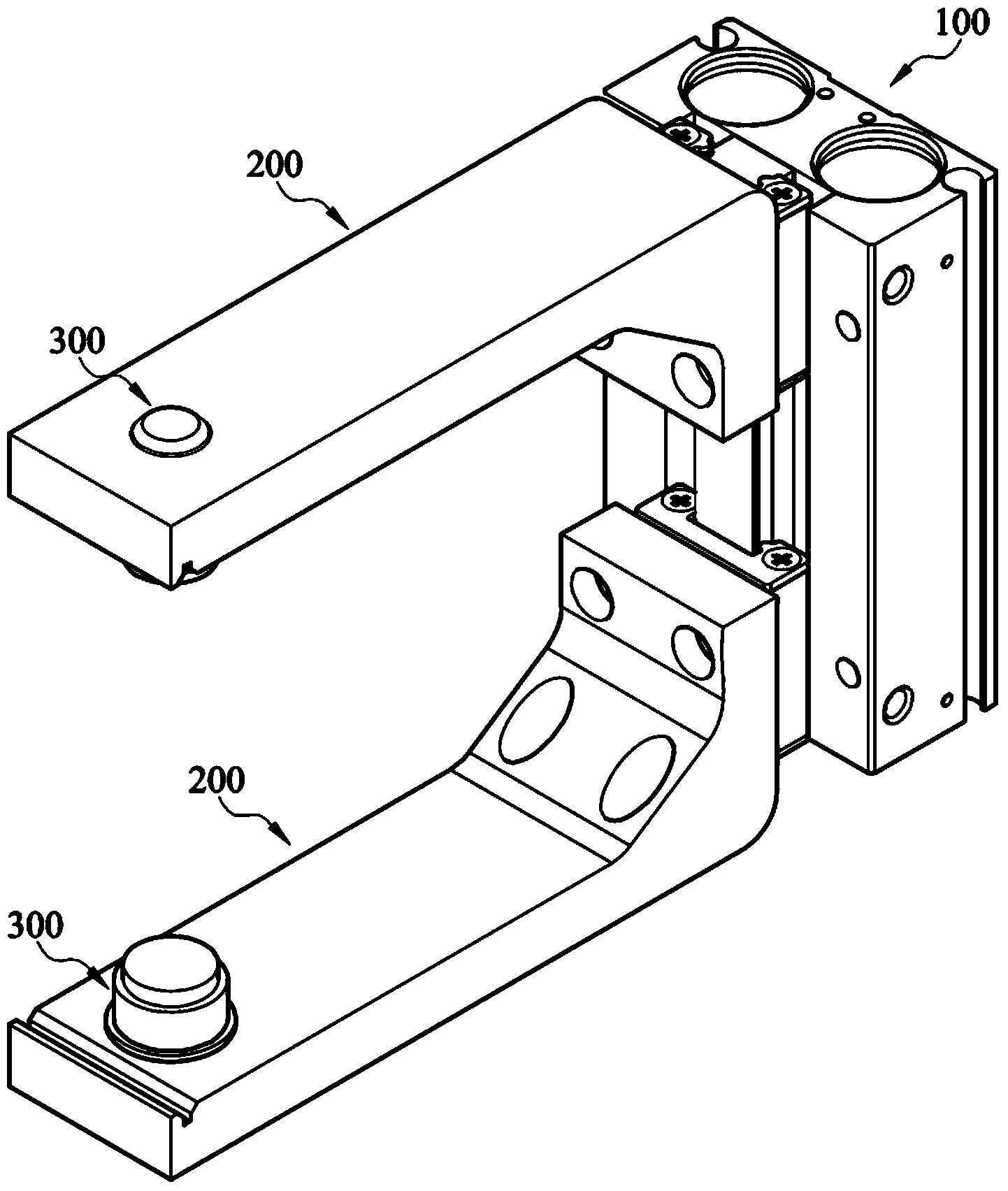

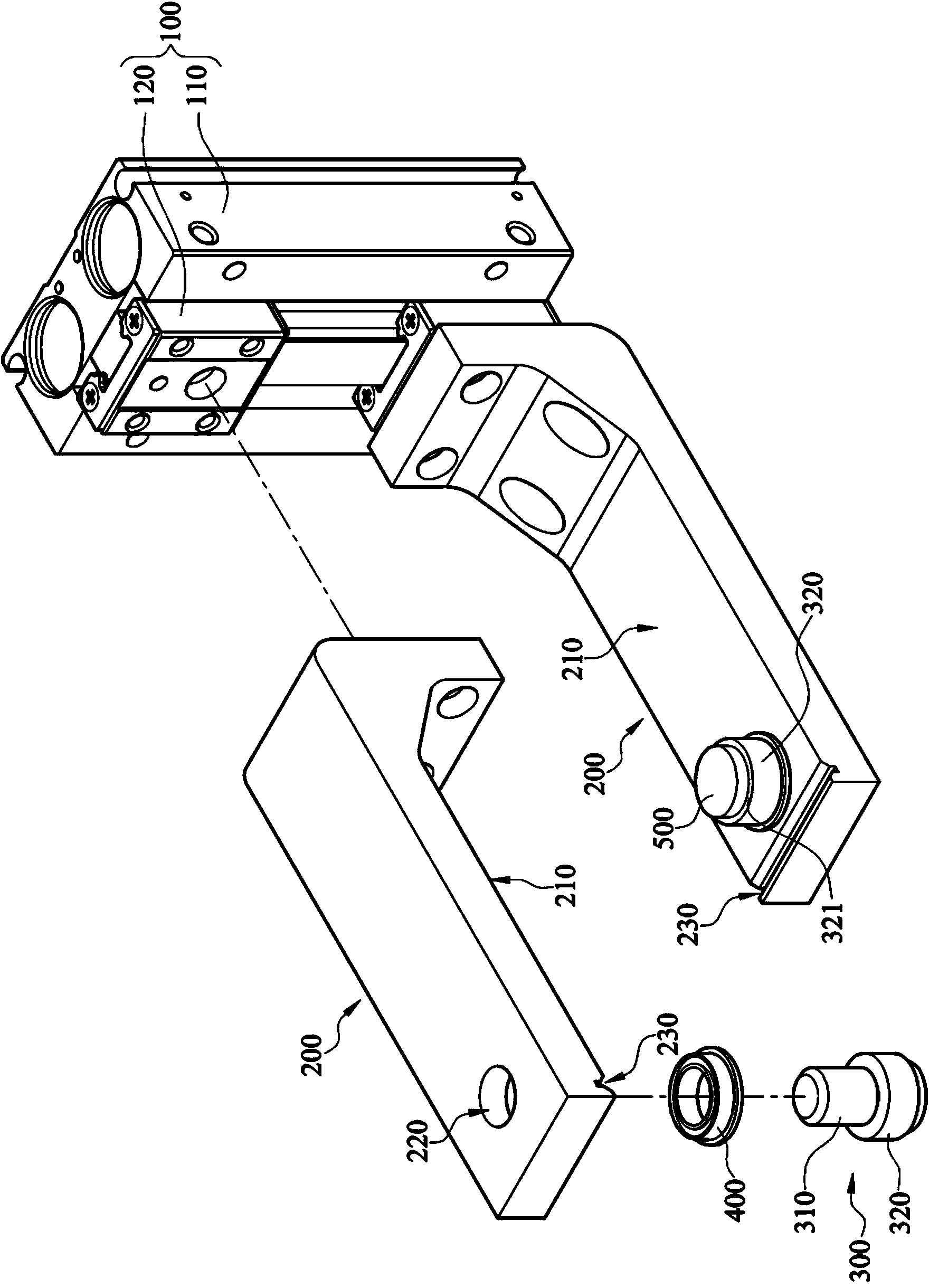

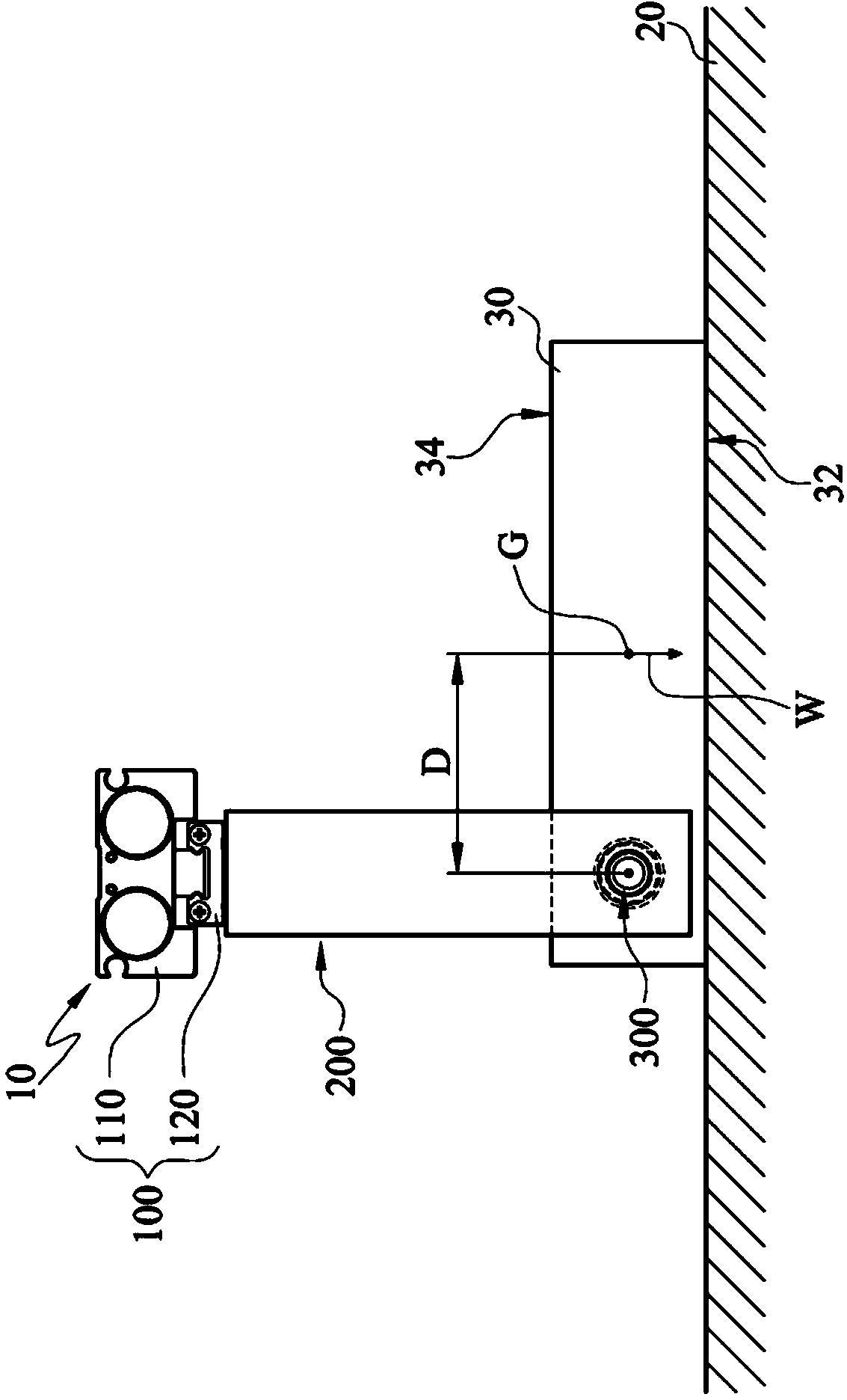

[0039] Please refer to Figure 1 to Figure 3 , figure 1 is a three-dimensional schematic diagram of a clamping mechanism with a flip function according to an embodiment of the present invention, figure 2 for figure 1 The decomposition diagram. image 3 for figure 1 A plan view of a workpiece clamped by the clamping mechanism with flipping function.

[0040] The clamping mechanism 10 with turning function of this embodiment is used to translate or turn over a workpiece 30 . The clamping mechanism 10 includes a base 100 , two movable jaws 200 , two non-powered clamping shafts 300 and two bearings 400 .

[0041] The base body 100 includes a sliding rail 110 and two sliding blocks 120 . The two sliding blocks 120 are respectively slidably disposed on the sliding rail 110 . The driving method between the slider 120 and the sliding rail 110 is, for example, pneumatic driving, hydraulic driving or electric driving.

[0042] The two movable claws 200 are respectively disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com