A producing method for producing concrete from mine waste ore and a producing system

A production method and technology for concrete, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of poor workability and pumpability of concrete, high consumption of total cementitious materials in concrete, and mining waste rock. problems such as poor grading, to reduce the risk of debris flow, slow down the process of grassland desertification, improve workability and pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A production method for making concrete by using mine waste rock, the concrete is prepared from the following raw materials in parts by weight:

[0028] 1500 parts of cement, 150 parts of fly ash, 400 parts of mine waste rock powder, 1500 parts of mine waste rock, 3500 parts of mine waste sand, 900 parts of water, 30 parts of water reducing agent, 5 parts of polyacrylamide;

[0029] Described production method comprises the following steps as follows:

[0030] (1) The mine waste rock is crushed by a pulverizer and sieved in turn to obtain mine waste rock powder with a particle size of 0.1mm-1mm, mine waste rock sand with a particle size of 1mm-10mm, and mine waste rock with a particle size of 10mm-30mm. Stones; Mine waste rock with a particle size greater than 30mm is sent back to the crusher (such as an impact crusher) for further crushing;

[0031] (2) Mix the crushed mine waste rock powder, mine waste stones and mine waste sand in step (1) with fly ash in proportion...

Embodiment 2

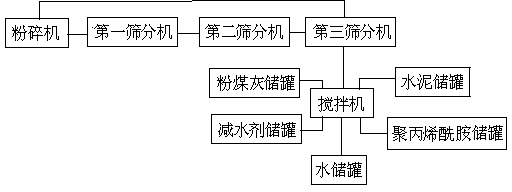

[0037] Such as figure 1 As shown, a production system for making concrete by using mine waste rock includes a pulverizer, and the pulverizer is connected with the first screening machine, the second screening machine, the third screening machine and the mixer in turn, and the third screening machine It is also connected to the pulverizer, and the mixer powder is also connected to the fly ash storage tank, cement storage tank, water storage tank, water reducer storage tank and polyacrylamide storage tank through pipelines;

[0038] Wherein, the screening particle diameter of the first screening machine is 0.1mm-1mm, the screening particle diameter of the second screening machine is 1mm-10mm, and the screening particle diameter of the third screening machine is 10mm-30mm.

[0039] In each embodiment of the present invention, the chemical materials used are the materials used in the production in this field, all can be obtained from the market, and will not have an impact on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com