Solid polyalcohol for oil field drilling fluid and its preparation method and application

A solid polymerization and drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as well wall collapse, inconvenience in transportation and use, and geological logging effects, etc., and achieve good results. The effect of oil and gas layer protection, low fluorescence level and low cloud point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

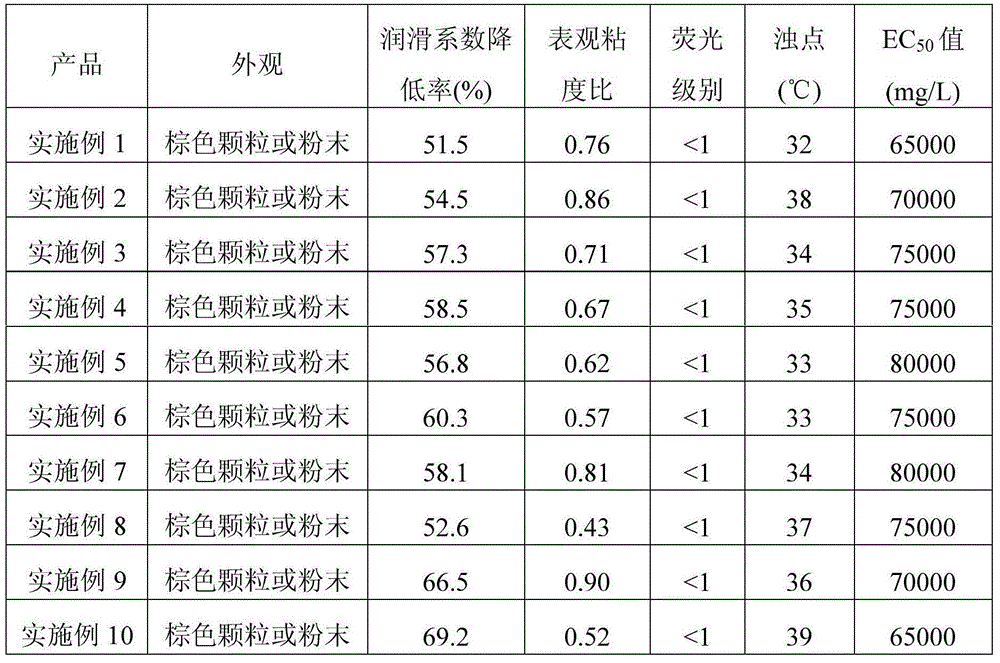

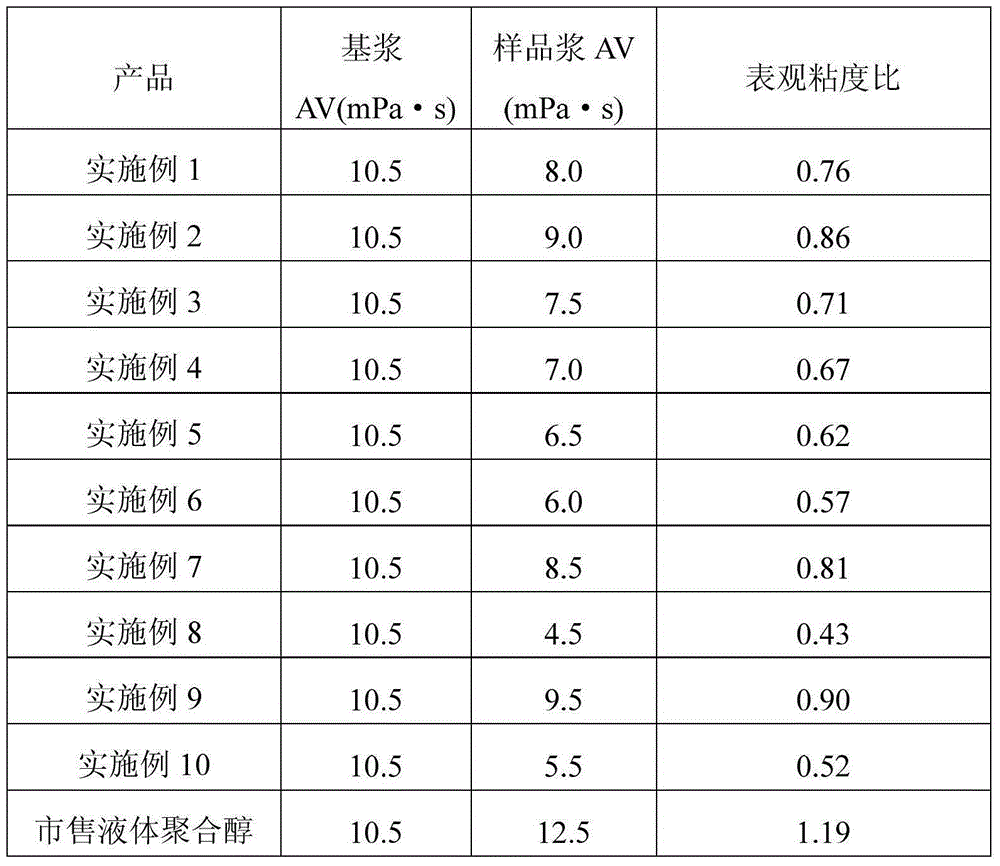

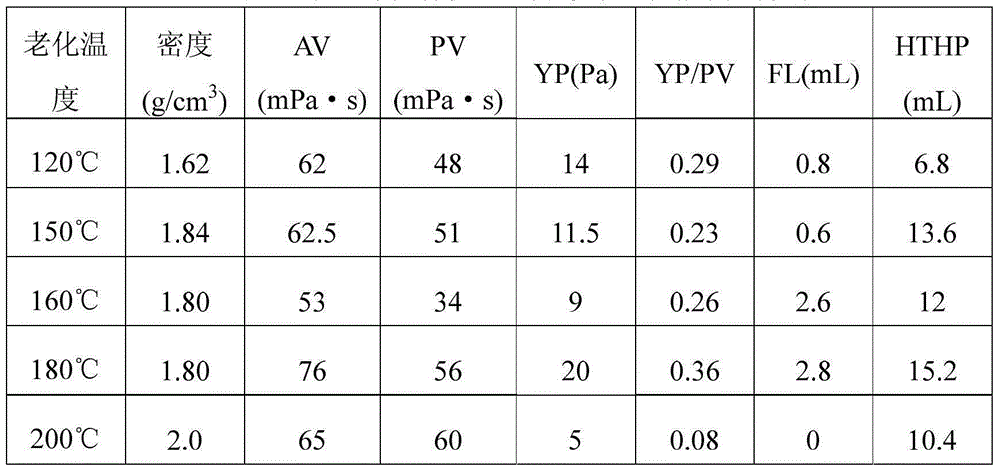

Examples

Embodiment 1

[0022] Add 1 part of stearylamine and 6 parts of KOH into the reaction kettle by weight ratio, fill with nitrogen to remove oxygen, then add 400 parts of ethylene oxide and 260 parts of propylene oxide, keep the pressure at 0.3MPa, and heat up to 155°C , reacted for 3.5 hours, and after cooling, the solid polymeric alcohol for drilling fluid of this embodiment was obtained.

Embodiment 2

[0024] Add 1.2 parts of palmitamine and 7 parts of KOH into the reaction kettle by weight ratio, fill with nitrogen to remove oxygen, then add 410 parts of ethylene oxide and 280 parts of propylene oxide, maintain the pressure at 0.2MPa, and heat up to 160°C , reacted for 4 hours, and after cooling, the solid polymeric alcohol for drilling fluid of this embodiment was obtained.

Embodiment 3

[0026] Take 0.6 part of stearylamine, 0.3 part of palmityl amine, 0.3 part of laurylamine and 7.5 parts of KOH in the reaction kettle by weight, fill with nitrogen to remove oxygen, then add 450 parts of ethylene oxide and 300 parts of propylene oxide, The pressure was maintained at 0.2 MPa, heated to 156° C., reacted for 4.5 hours, and cooled to obtain the solid polymeric alcohol for drilling fluid of this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com