Method for ingoting polycrystalline silicon

A technology of polycrystalline silicon and ingot casting, which is applied in the field of solar cells, can solve the problems of low crystallization rate of silicon ingots, reduced production capacity of silicon wafers, and increased production costs, and achieve high conversion efficiency, low production costs, and good vertical growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

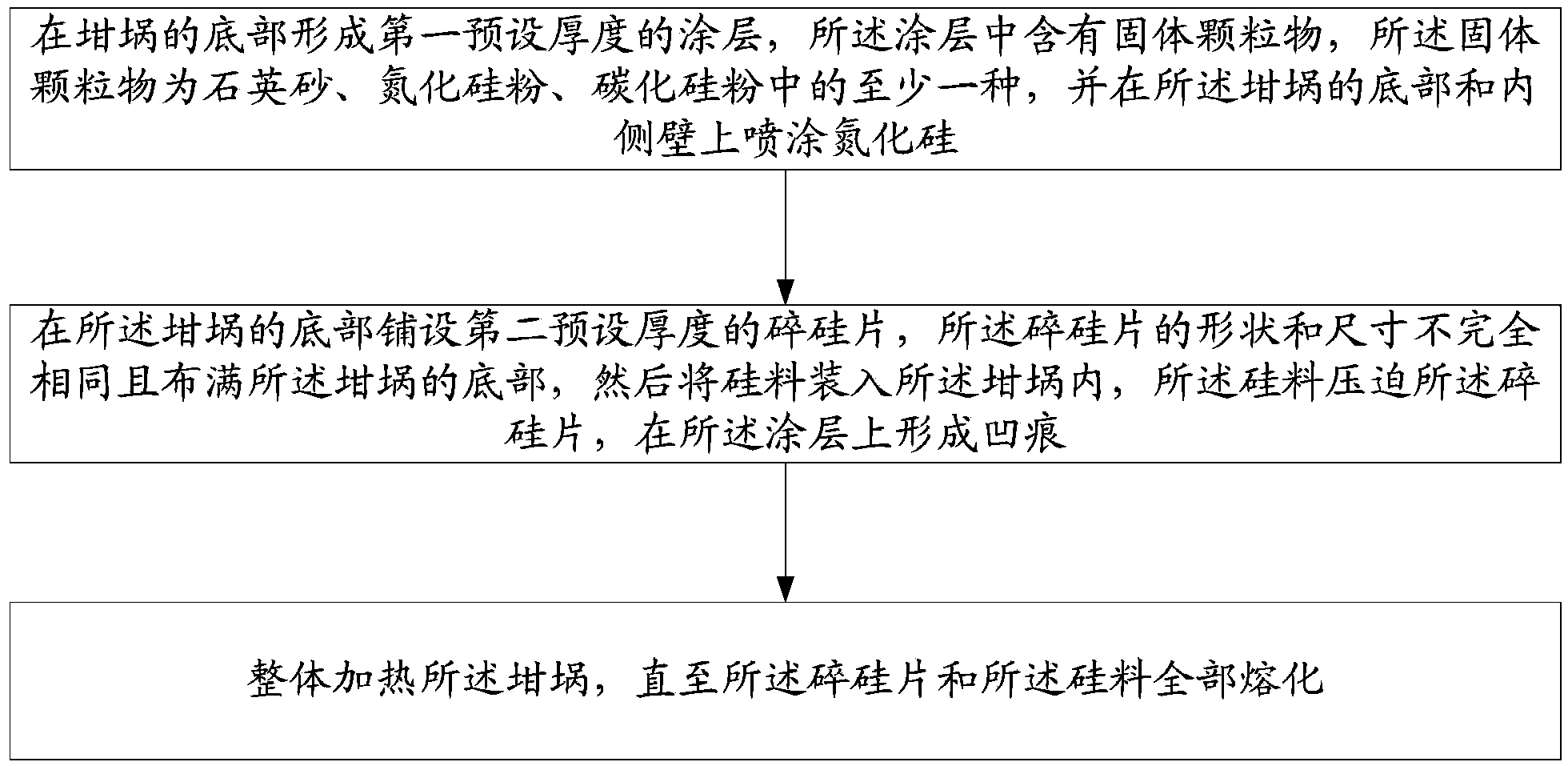

Method used

Image

Examples

Embodiment Construction

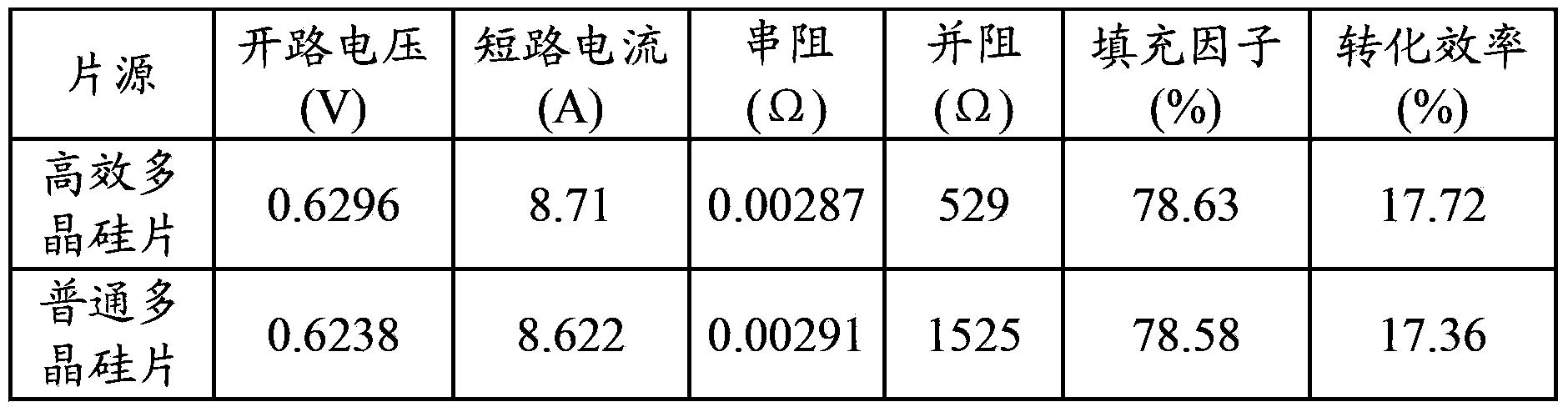

[0021] As mentioned in the background art, the conventional high-efficiency polycrystalline silicon ingot casting method has high energy consumption and low crystallization rate. The inventor found that the reason for the above phenomenon is that the main means to improve the conversion efficiency of polycrystalline silicon ingots is to improve the consistency and directionality of crystal grains and reduce dislocations. Growth, and then to ensure the consistency and directionality of the crystal grains, will keep about 20mm of silicon material incompletely melted in the late stage of silicon material melting as the seed crystal during crystal growth. In the melting stage, if the method of heating the crucible as a whole to melt the silicon material during the ordinary polysilicon ingot casting is adopted, due to the fluidity of the silicon liquid, the silicon liquid will gather at the bottom of the crucible, and the solid silicon material will float on the silicon liquid, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com