Slidable cylinder cover type variable compression ratio engine

A compression ratio, engine technology, applied in engine components, engine control, machine/engine, etc., can solve problems such as poor stability, complex structure, difficult control, etc., to achieve the effect of expanding bandwidth, simple control, and improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

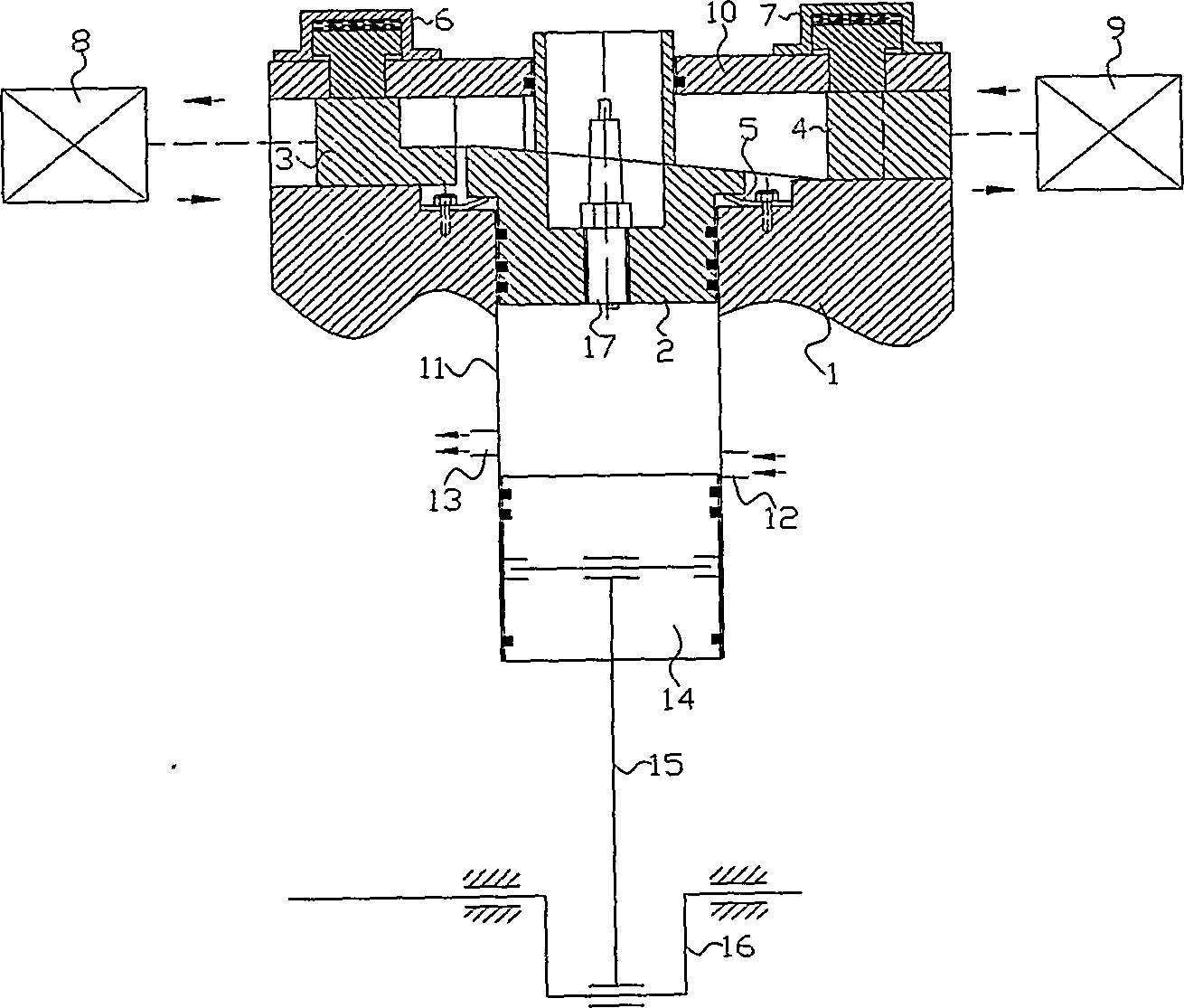

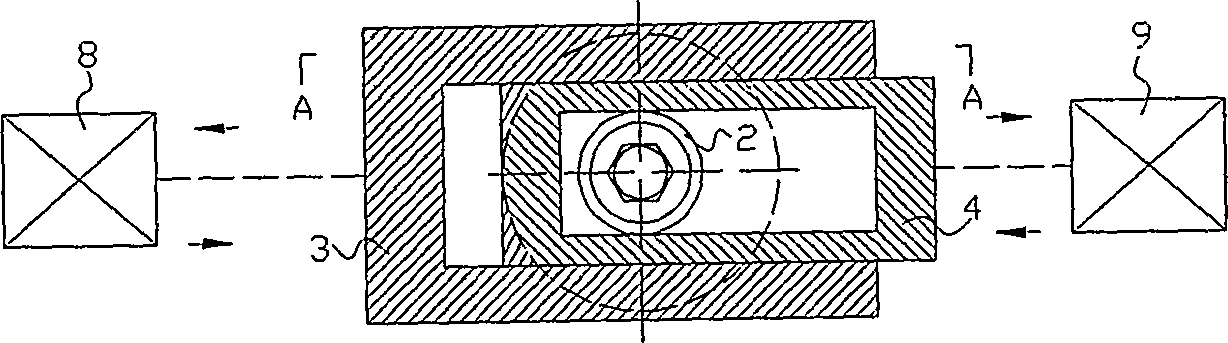

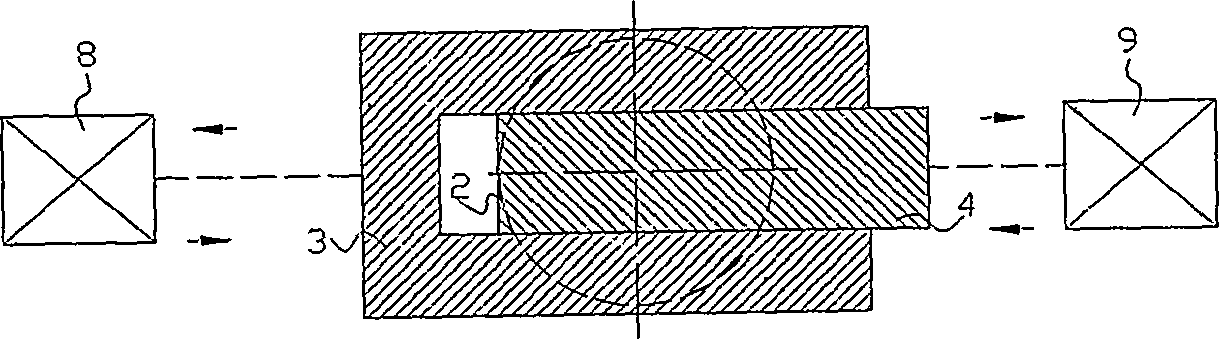

[0022] The engine ECU controls the actuator to slide the slider back and forth, and the slider then drives the cylinder head to move up and down to change the compression ratio of the engine. The slider moves forward, the cylinder head goes down, and the compression ratio becomes larger. When the engine knock sensor detects knock, the ECU sends an instruction to the actuator, and the control slider moves back to reduce the compression ratio to eliminate knock. Under various working conditions, the ECU will control the actuator to use the engine with the most suitable compression Ratio, try to make the engine run under the condition of large compression ratio without knocking, which can improve fuel efficiency and reduce emission pollution. The slider is equipped with a position sensor, which sends a signal to the ECU to determine the specific position of the slider. Location.

[0023] The engine ECU will set the position of the main and auxiliary sliders according to the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com