Yaw system and manufacturing method thereof for vertical axis wind turbine as well as wind energy ship with yaw system

A yaw system and wind turbine technology, which is applied in the control of wind turbines, wind turbines, engine functions, etc., can solve the problems of large turbulence, difficulty in making high power, and limit the installation height of wind turbines, so as to improve efficiency and utilize wind energy. The effect of high coefficient and large lift-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

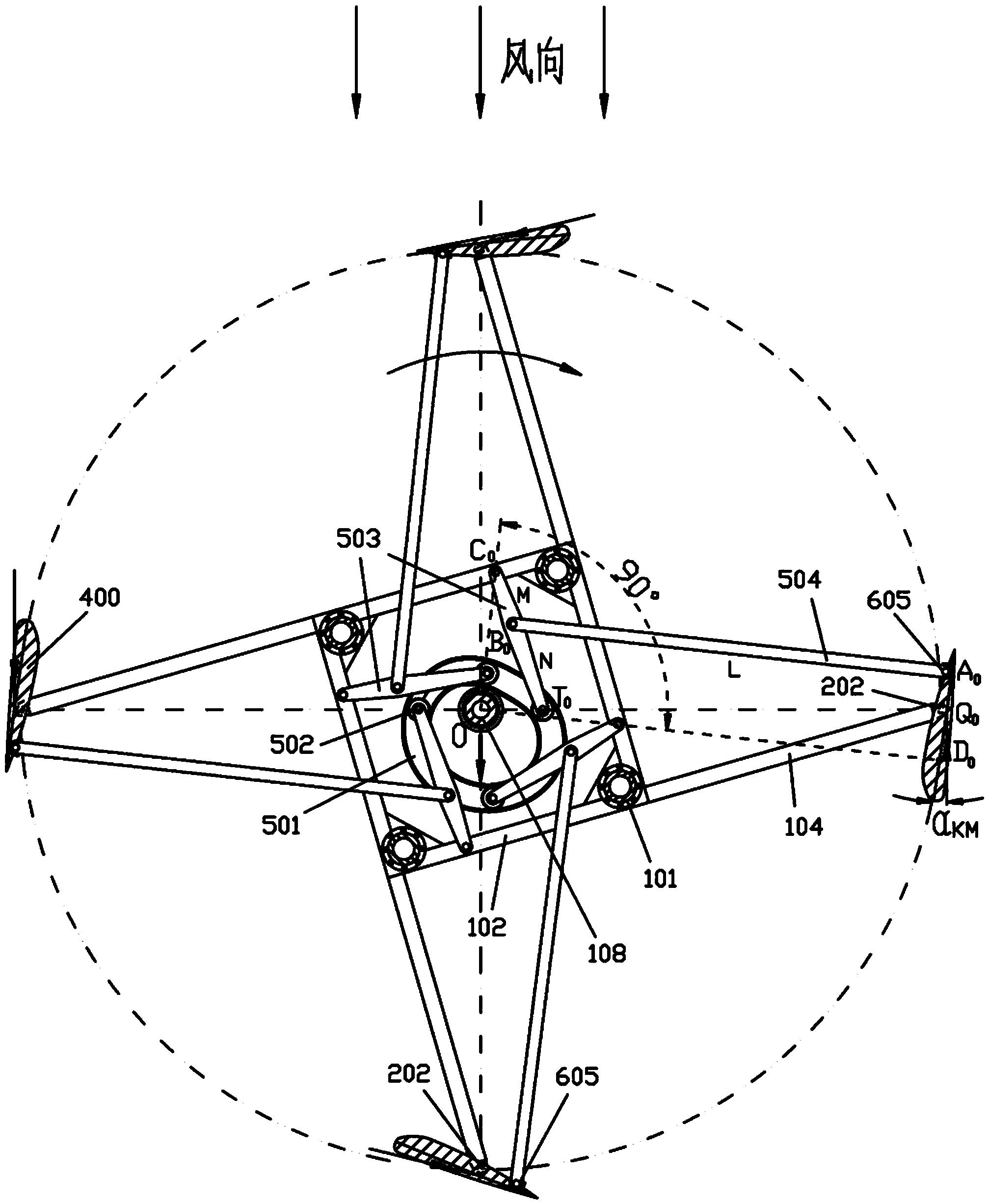

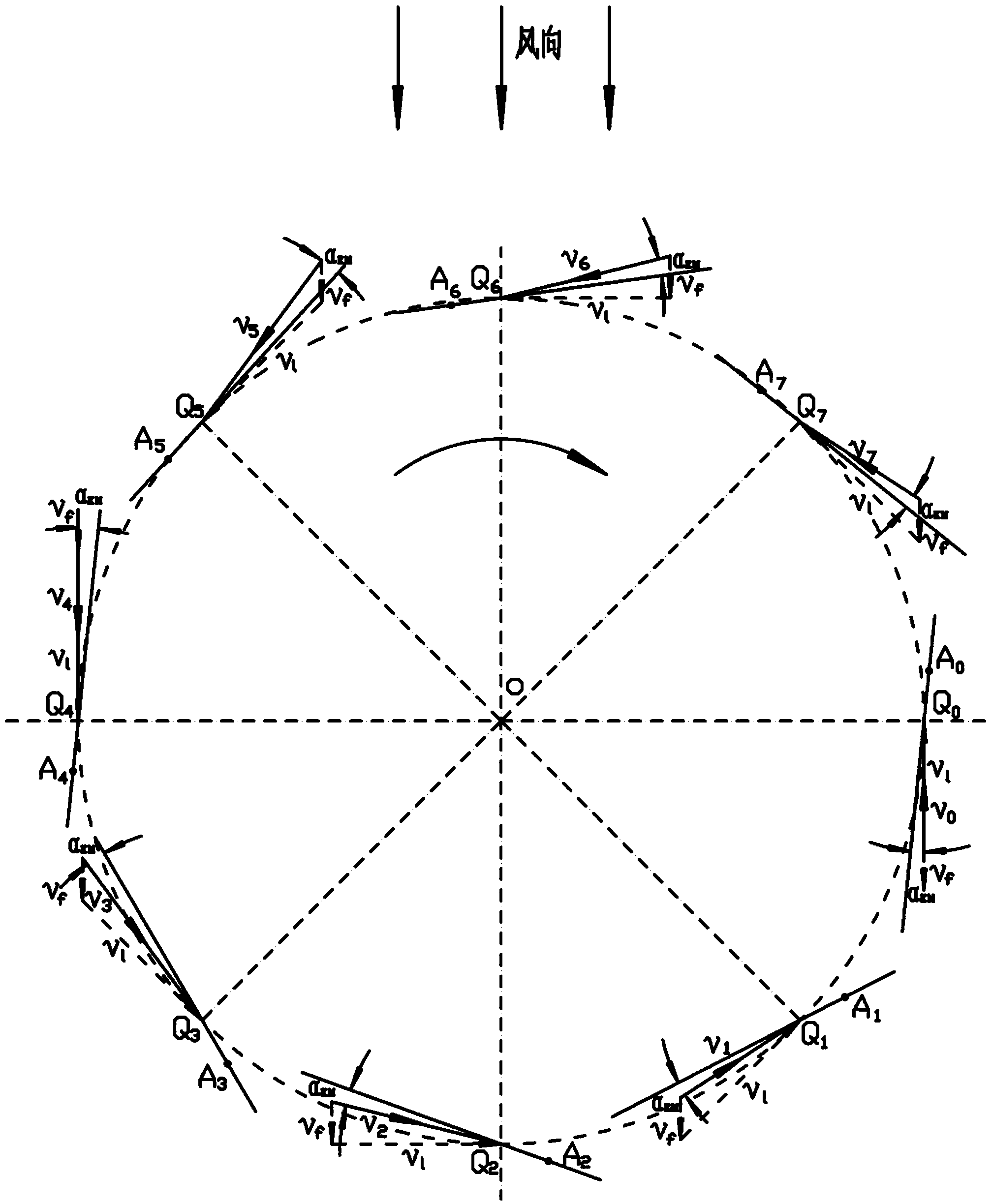

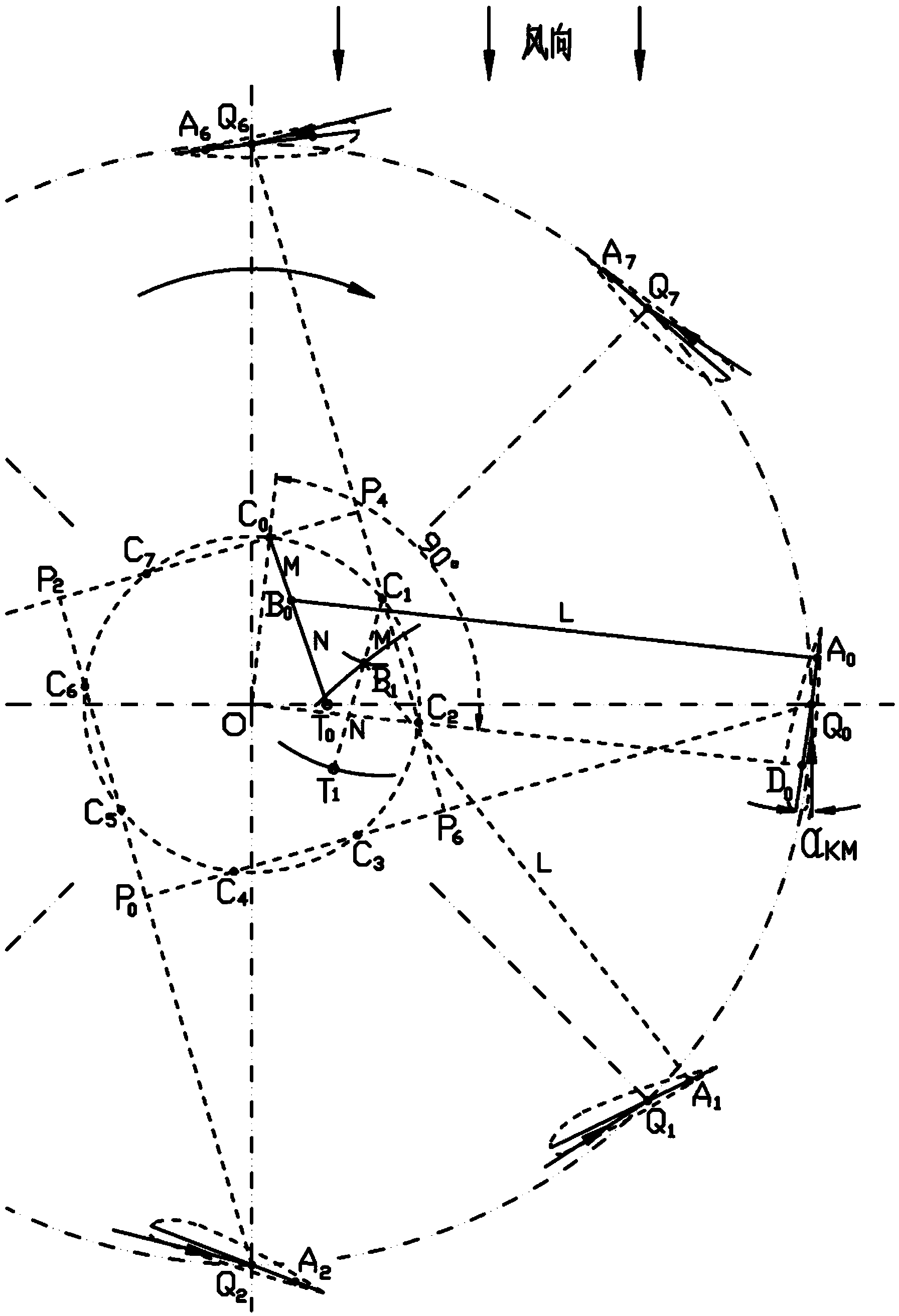

[0045] When the wind wheel rotates, the yaw wheel 502 runs in the grooved guide rail, which will generate a reaction force to the yaw guide rail wheel 501, so that its "orientation radius" cannot be consistent with the wind direction, resulting in yaw failure. Therefore, the yaw guide wheel 501 must be able to lock the wind direction at any time, and only rotate with the change of the wind direction without being affected by other factors. The yaw system of the present invention is divided into two types according to the way of adjusting and locking the wind direction: an active yaw system and a passive yaw system.

[0046] Figure 6 It is a simplified schematic diagram of an active yaw system structure. The driving mechanism is a steering motor 510, and the steering motor 510 is connected with a vertical transmission shaft 515 through a steering worm gear 507. In the figure, the yaw guide wheel 501 is located in its grooved guide rail and is the yaw wheel 502 . The yaw whe...

Embodiment 2

[0048] see Figure 7 and Figure 8 , is an example of the steering drive mechanism of the passive yaw system, including the steering gear 511 and the steering pinion 512, the steering gear 511 is rotatably installed on the tower body 300 in a horizontal state relying on a set of guide wheels 513, A wind vane 514 is fixed on the steering gear 511; the steering pinion 512 meshes with the steering gear 511, and the steering pinion 512 is connected with the worm of the steering worm gear 507 through a horizontal transmission shaft 515, and the worm gear is connected to the vertical Drive shaft 515 is connected.

[0049] The passive yaw system is used for non-power generation purposes (such as pumping water, etc.) in areas without electricity, and has unique advantages. The working principle of this system is similar to that of the active yaw system, and it also has the function of wind direction locking. The difference is that the steering worm gear 507 is not driven by a motor...

Embodiment 3

[0052] Figure 9-11 It is another form of passive yaw system, which is suitable for wind turbines using truss towers with large spans. It works with Figure 7-8 As shown, the direction adjustment drive mechanism includes a tubular shaft 516 rotatably installed on the tower body 300, a wind vane 514 is fixed on the tubular shaft 516, and a direction adjustment gear 511 is fixed on the tubular shaft 516. The transmission shaft 515 is provided with a steering pinion 512 , and the steering gear 511 is meshed with the steering pinion 512 . The steering pinion is connected to the worm of the worm gear 507 , the lower end of the vertical transmission shaft 515 is connected to the worm gear, and the upper end is connected to the steering main gear 508 .

[0053] The requirements for components in the system are also similar, the difference is that components such as the wind vane 514, the steering gear 511, and the steering pinion 512 are moved into the tower body. Both the wind va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com