Solid propellant multi-target wire dynamic combustion performance testing system and method thereof

A technology of solid propellant and combustion performance, which is applied in the direction of chemical analysis using combustion, can solve the problems of complex testing process, large amount of propellant, and many testers, so as to reduce manual operation, reduce raw material consumption, and facilitate switching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

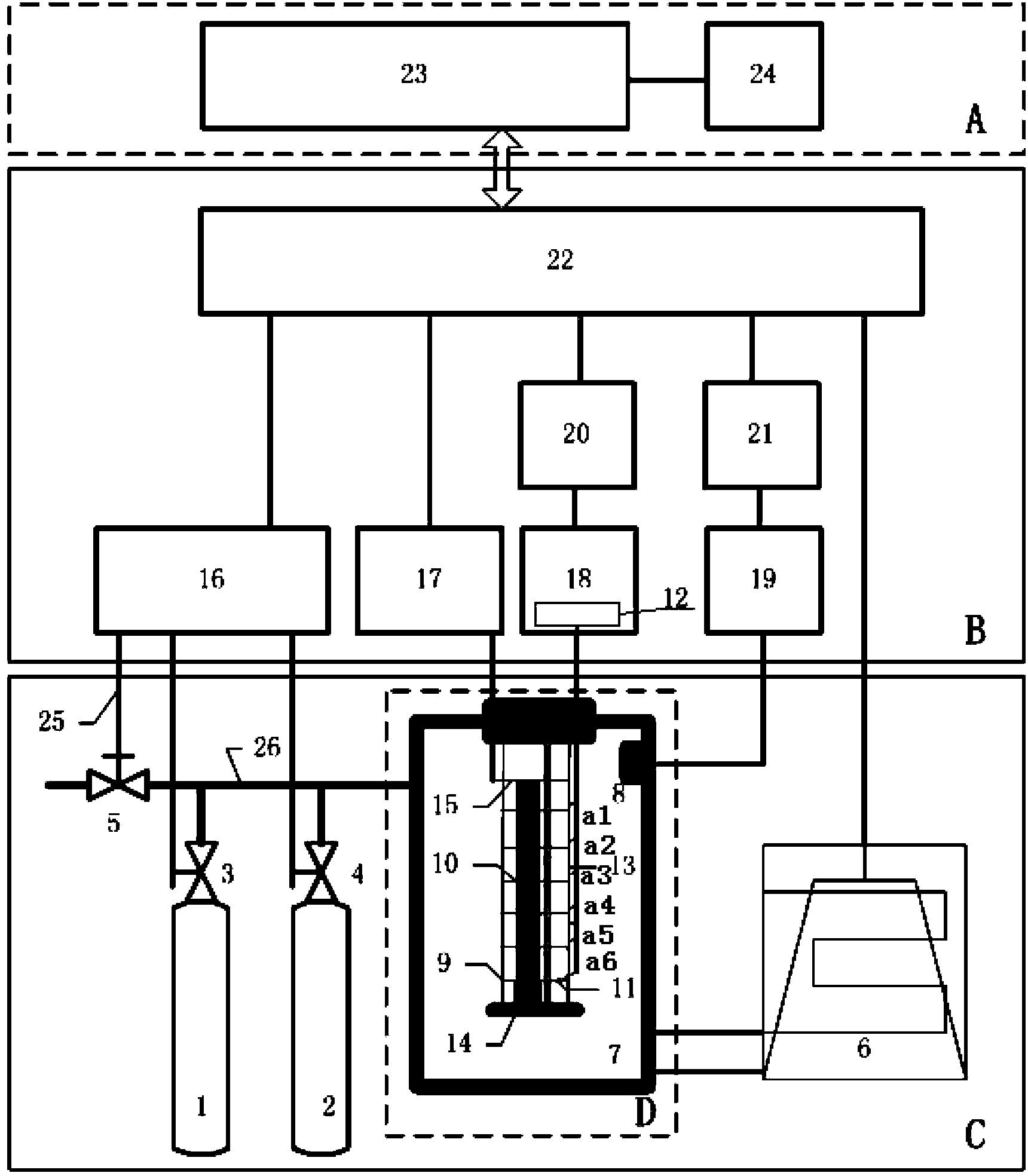

[0050] refer to figure 1, a solid propellant multi-target line dynamic combustion performance test system, at least including:

[0051] Combustion chamber unit D, which provides the combustion chamber for solid propellant sample combustion and the initial environment required for testing.

[0052] The wall of the combustion chamber has a surrounding pipeline connected to the constant temperature bath 6; the combustion chamber 7 has an air hole and a mounting hole for the temperature and pressure sensor 8, through which the air circuit unit and the temperature and pressure sensor 8 are connected respectively, and a filter is provided at the air hole.

[0053] The combustion bracket is provided with a positioning grid 13 for positioning and connecting the multi-target wire 11 and the ignition wire 15 . The metal rod plays the role of support and ground wire. One end of the multi-target wire 11 passes through the solid propellant pill 10, and the other end is connected to a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com