Alignment device

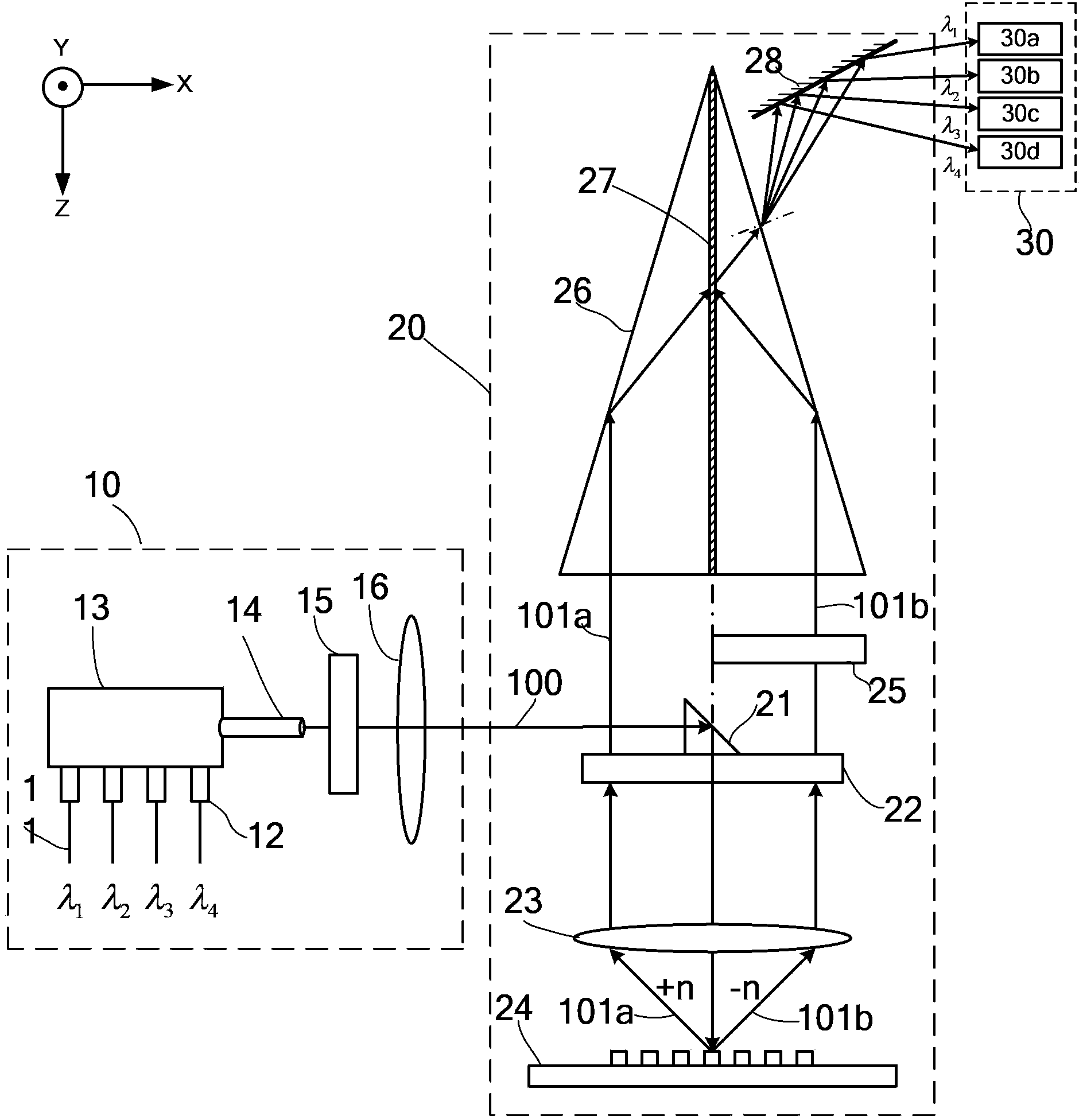

An aligning device and prism technology, applied in the field of semiconductors, can solve problems such as high requirements for prism processing and assembly and adjustment tolerance, difficult gluing of prism groups, etc., and achieve the effects of increasing detection light intensity, simplifying structure, and reducing processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

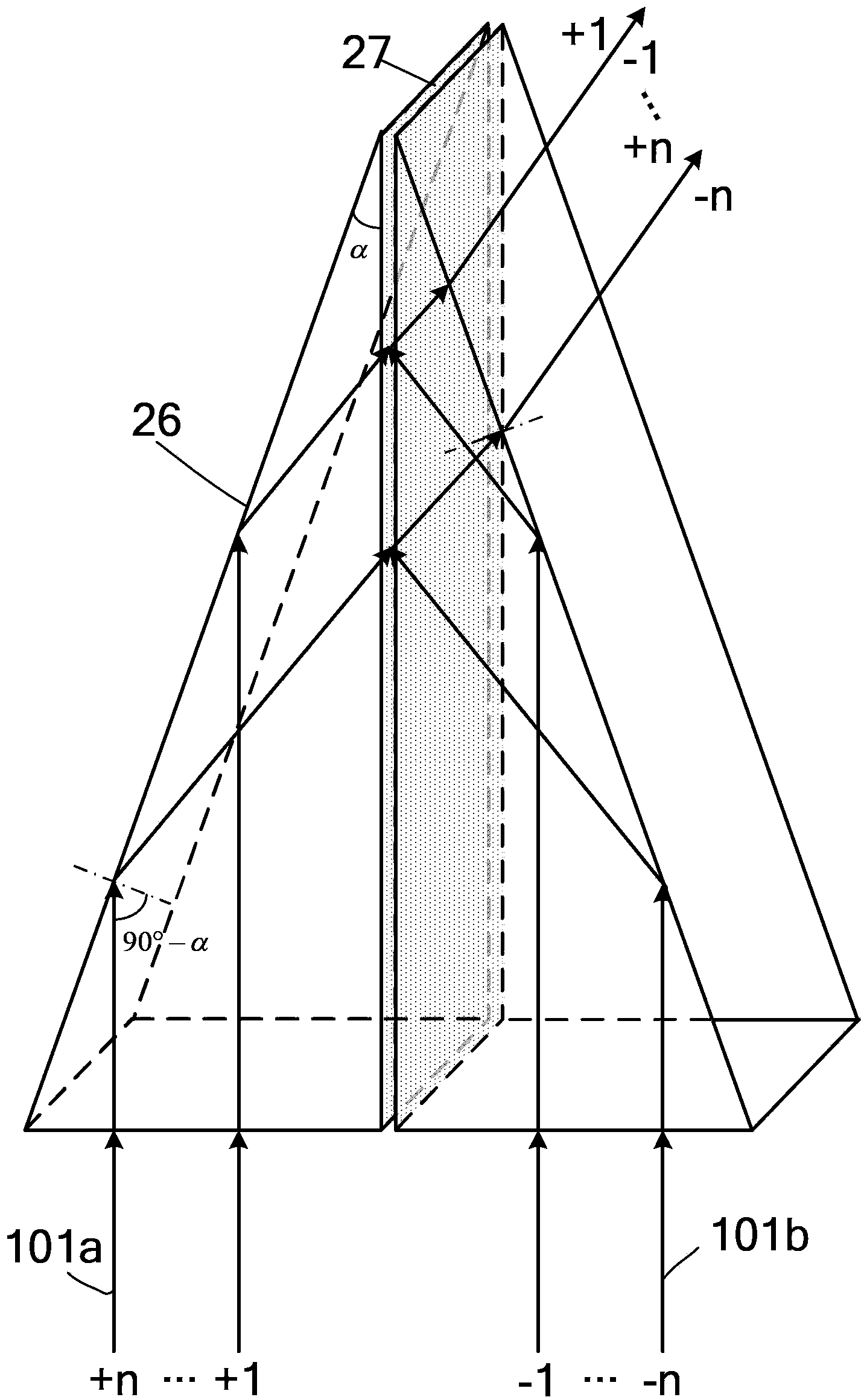

Method used

Image

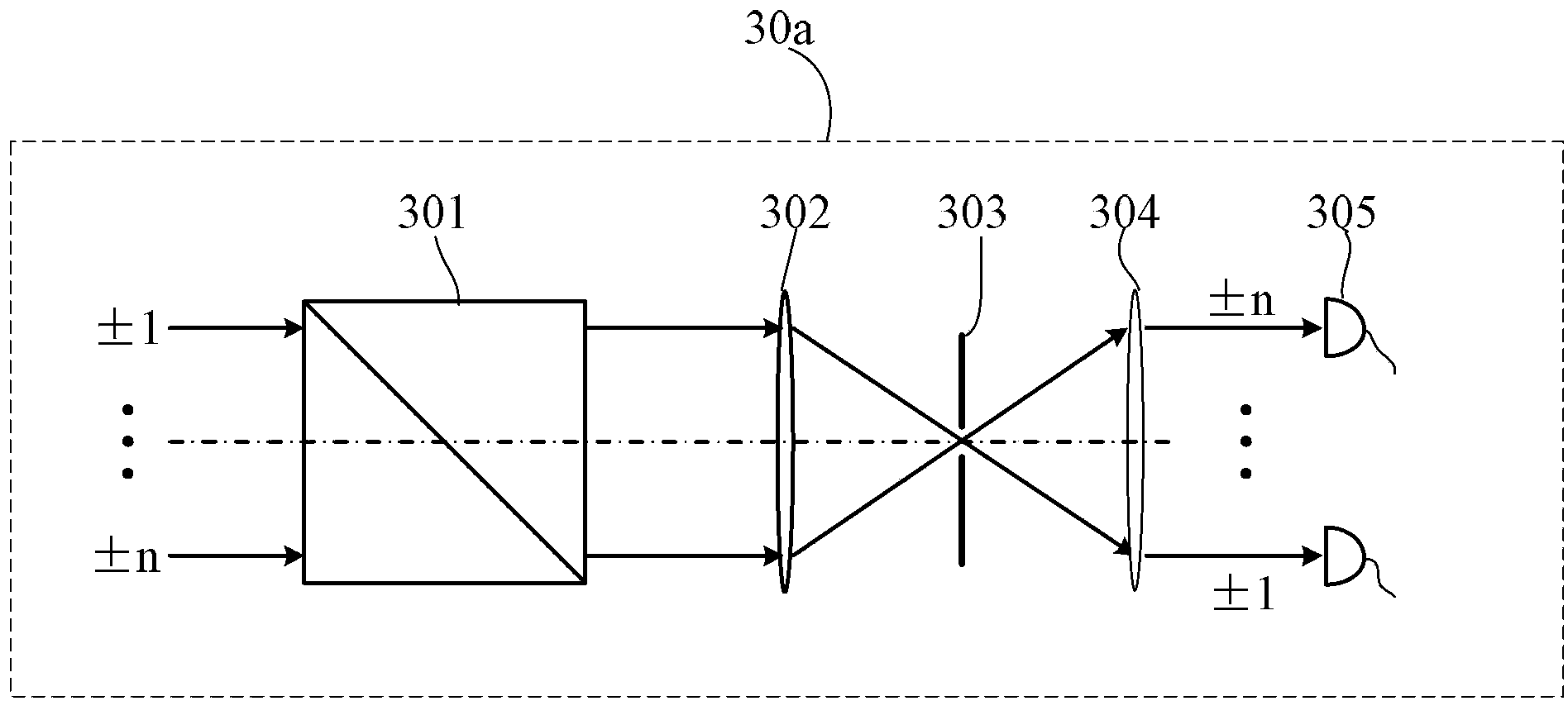

Examples

Embodiment 2

[0070] Please refer to Figure 7 , the difference between this embodiment and Embodiment 1 is that: the number of the detection module 30 is two, the interference module 20 also includes another set of Koster (Koster) prisms 26 and a beam splitter 50, the The positive and negative sub-diffraction lights are divided into two mutually perpendicular diffracted light path parts by the beam splitter 50, and enter two sets of Koster prisms 26 respectively, and then pass through two sets of Koster prisms 26 to form two Part of the detection light, two parts of the detection light are respectively converted into interference signals by the two detection modules and collected, so that the position information of the alignment mark 24 in two directions can be obtained by collecting the information of the interference signals obtained , in this embodiment, that is, the position information in the x direction and the y direction.

[0071] To sum up, the present invention uses the combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com