Preparing method of neutron absorbing plate for storage and transportation of nuclear fuel

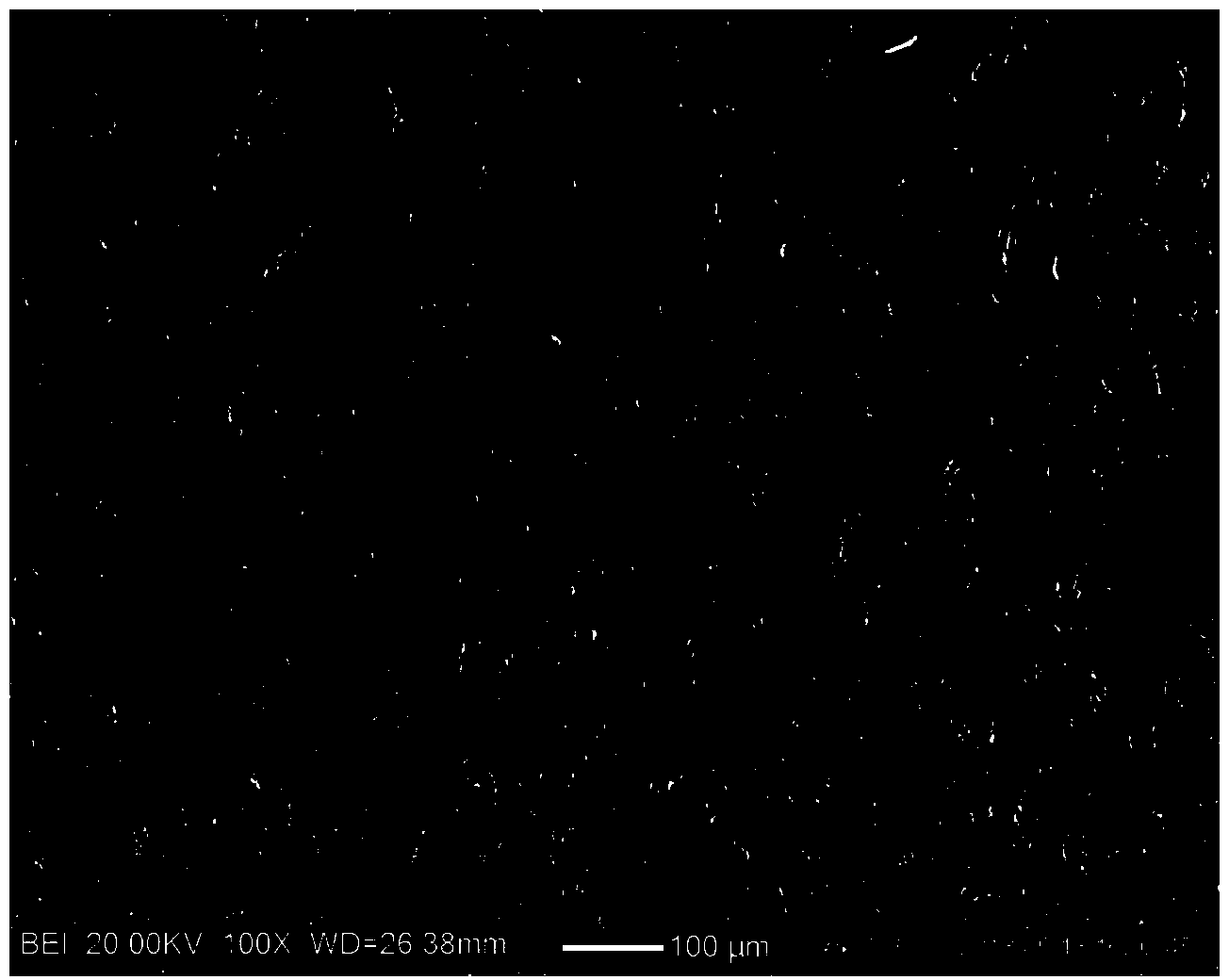

A neutron absorption plate, nuclear fuel technology, applied in nuclear engineering, reactor, shielding and other directions, can solve the problems of difficult nuclear radiation and leakage protection, weak protection performance, low mechanical performance, etc., to achieve accurate data, metallographic structure, etc. Good compactness and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with accompanying drawing:

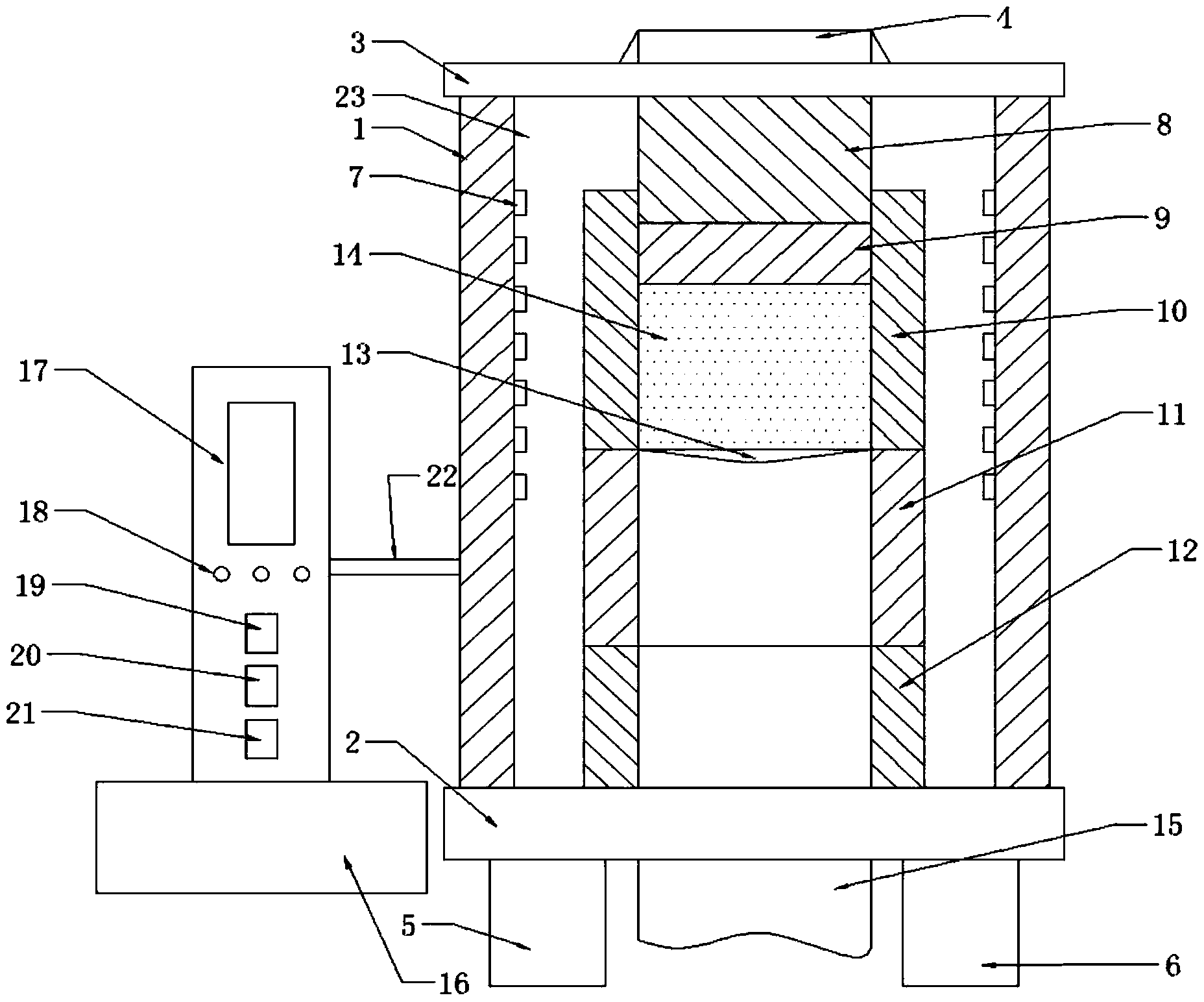

[0068] figure 1 As shown in the figure, it is the hot extrusion molding state diagram of the neutron absorbing plate, and the various positions and connection relations must be correct and operated in sequence.

[0069] The hot extrusion molding of the neutron absorbing plate is carried out on a hot extruding machine, which is vertical, and the neutron absorbing plate is formed in a heated and shaped diversion mold; the lower part of the hot extruding machine 1 is the base 2. The upper part is the top seat 3, and the inside is the extruder chamber 23; the left bracket 5 and the right bracket 6 are arranged on the left and right sides of the lower part of the base 2; the pressure motor 4 is arranged on the upper part of the top seat 3; The upper part of the base 2 is provided with an extrusion die, the lower part of the extrusion die is the exporting die 12, the upper part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com