Patch pasting method and device for patch head of patch pasting machine

A technology of placement head and placement machine, which is applied in the direction of assembling printed circuits with electrical components, electrical components, and printed circuit manufacturing, etc., can solve the problems of invariable distance adjustment and inability to adjust, and achieve the effect of reliable adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

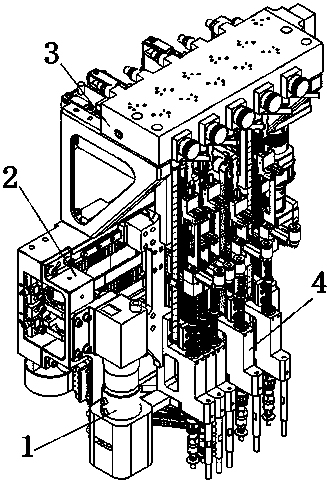

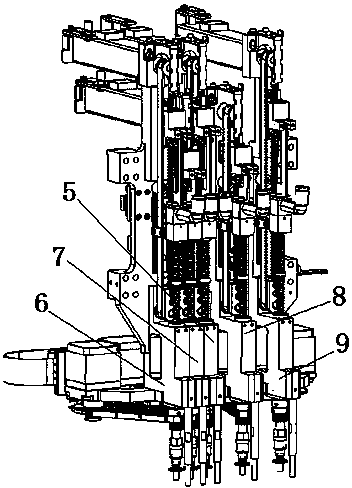

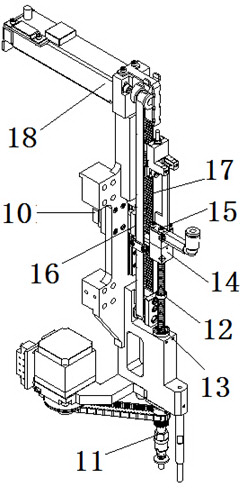

[0032] attached Figure 1-8 A technical embodiment of the present invention is given. It can be seen from the accompanying drawings that the present invention relates to a placement head of a placement machine. The placement head is composed of five mutually independent placement head suction nozzle assemblies 4 and a mark camera assembly 1, a placement head mounting backplane assembly 2 and a pneumatic valve. The island seat assembly 3 is combined; among them, the mark camera assembly 1 is fixed on the mount head installation backplane 2 through two connecting plates, and is used for taking pictures and positioning the PCB board during the mount process; the mount head suction nozzle assembly 4, the pneumatic valve The island seat assembly 3 is connected with the installation back plate assembly 2, and the nozzle head assembly of the patch head suction nozzle assembly 4 drives the suction nozzle to move up and down on the STAR axis, and the pneumatic valve island seat assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com