Organic-material refining device

A technology of organic materials and cylinders, which is applied in the field of purification devices for organic materials, can solve the problems of reduced purification efficiency and time-consuming, and achieve the effects of easy recovery, accurate measurement and control, and improved purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0067] (1) The structure of the purification device

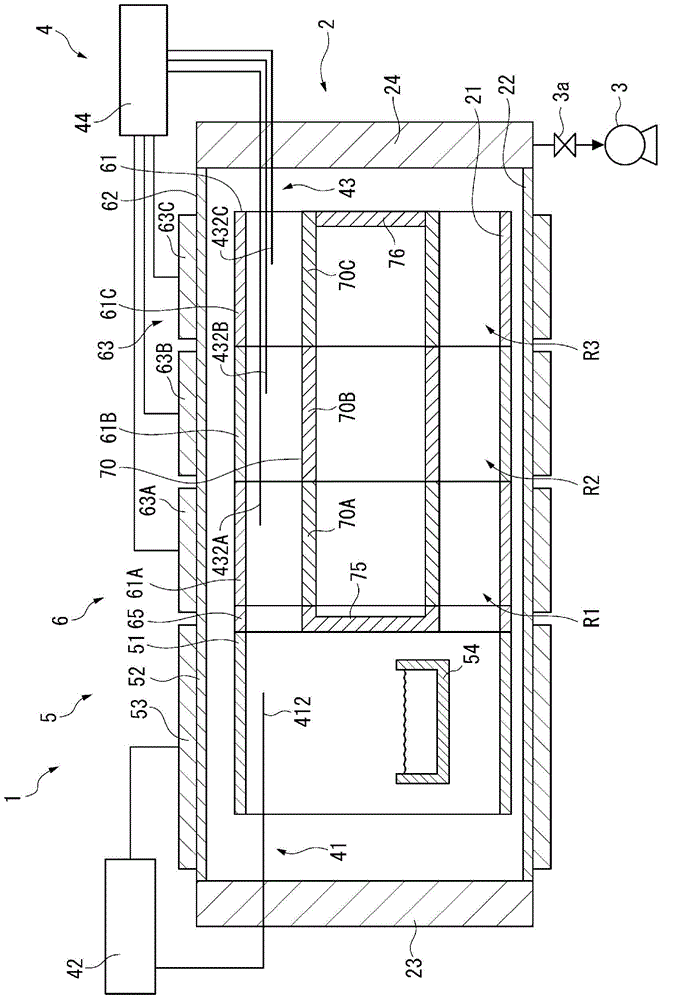

[0068] exist figure 1 A schematic cross-sectional view taken along the longitudinal direction of the organic material purification device 1 according to the first embodiment is shown in .

[0069] The purification apparatus 1 includes an apparatus main body 2 for purifying an organic material, a vacuum pump 3 as an exhaust device for depressurizing the inside of the apparatus main body 2 , and a temperature controller 4 for controlling the temperature of the apparatus main body 2 . Hereinafter, the case of purifying the material for an organic EL element will be described as an example.

[0070] (1-1) Device main body

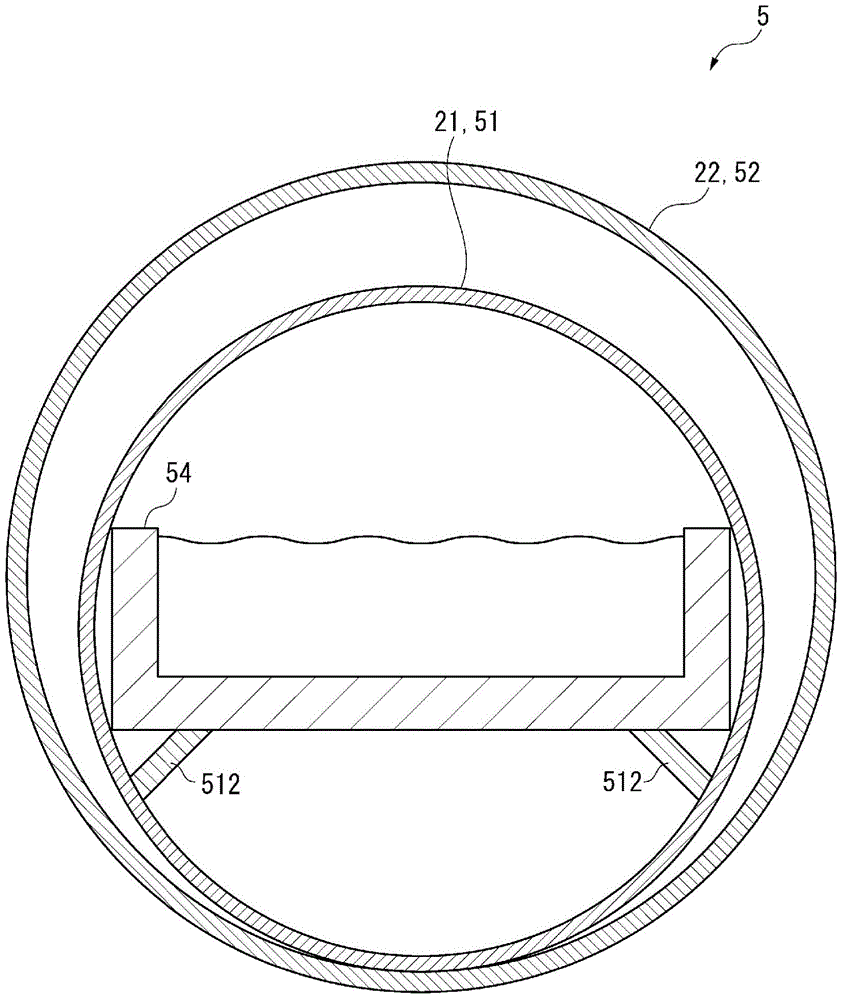

[0071] The device main body 2 adopts a double tube structure, and is provided with a cylindrical inner cylinder 21 and a cylindrical outer cylinder 22. The outer cylinder 22 is disposed outside the inner cylinder 21 and accommodates the inner cylinder 21 in Inside, both ends of the outer cylindrical body ...

no. 2 approach

[0132] Next, an apparatus for purifying an organic EL element material according to a second embodiment of the present invention will be described.

[0133] It should be noted that, in the following description, the same reference numerals are assigned to the same parts as those already described, and the description thereof will be omitted or simplified.

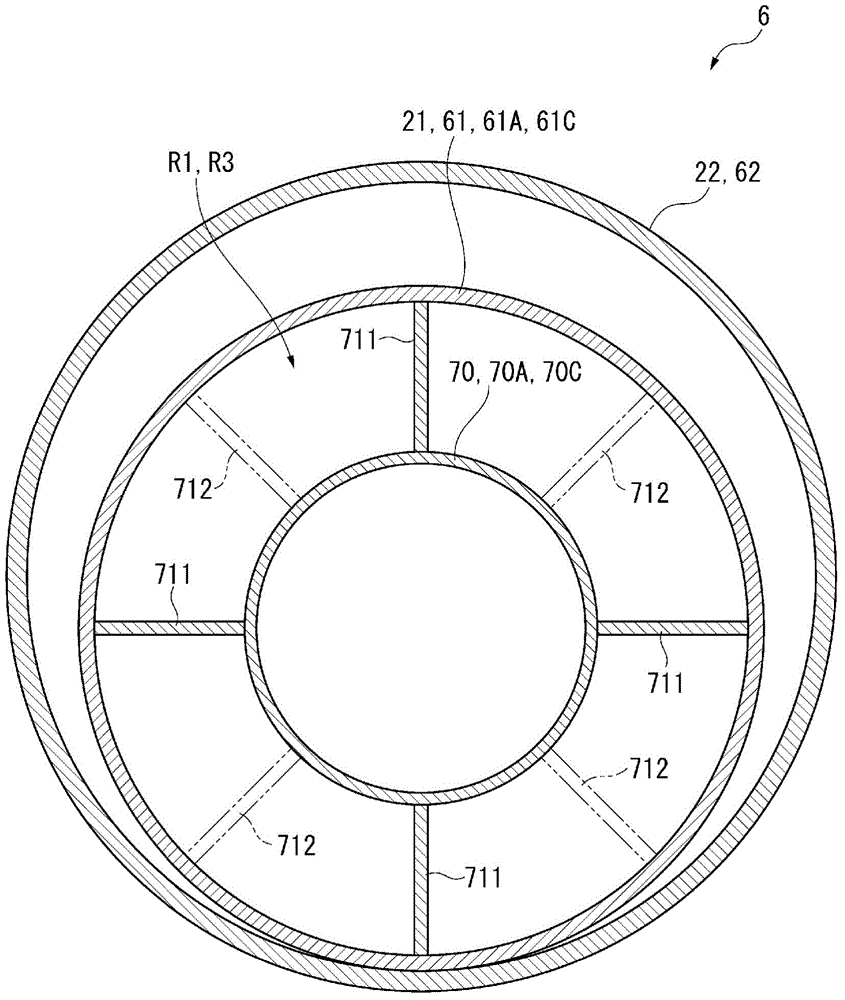

[0134] exist Figure 8 A perspective view of the second inner cylinder 67 included in the organic material purification device of the second embodiment is shown in FIG. Figure 9 A perspective view of the third cylindrical body 72 arranged inside the second inner cylindrical body 67 is shown in .

[0135] The shape of the second inner cylinder 67 is almost the same as that of the second inner cylinder 61 of the first embodiment, except that the second inner cylinder 67 can be divided into two.

[0136] The shape of the third cylinder 72 as the collection area expanding member is almost the same as that of the third cylind...

no. 3 approach

[0145] Next, 1A of purifying apparatuses for organic EL element materials according to a third embodiment of the present invention will be described. It should be noted that in the following description, the same reference numerals will be assigned to the same parts as those already described, and the description thereof will be omitted or simplified.

[0146] exist Figure 10 A schematic cross-sectional view of an organic material purification device according to a third embodiment is shown in . The purification apparatus 1A of an organic EL element material according to the third embodiment is different from the above-mentioned embodiment in the shape of the collection area expanding member arranged inside the second inner cylindrical body 61 . Since the other points are almost the same, descriptions are omitted or simplified.

[0147] The collection area expanding member used in the purification device 1A is a lattice member 80 formed by combining a plurality of plate-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com