Solder paste

A solder paste and flux technology, used in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as poor stability and achieve the effect of maintaining meltability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

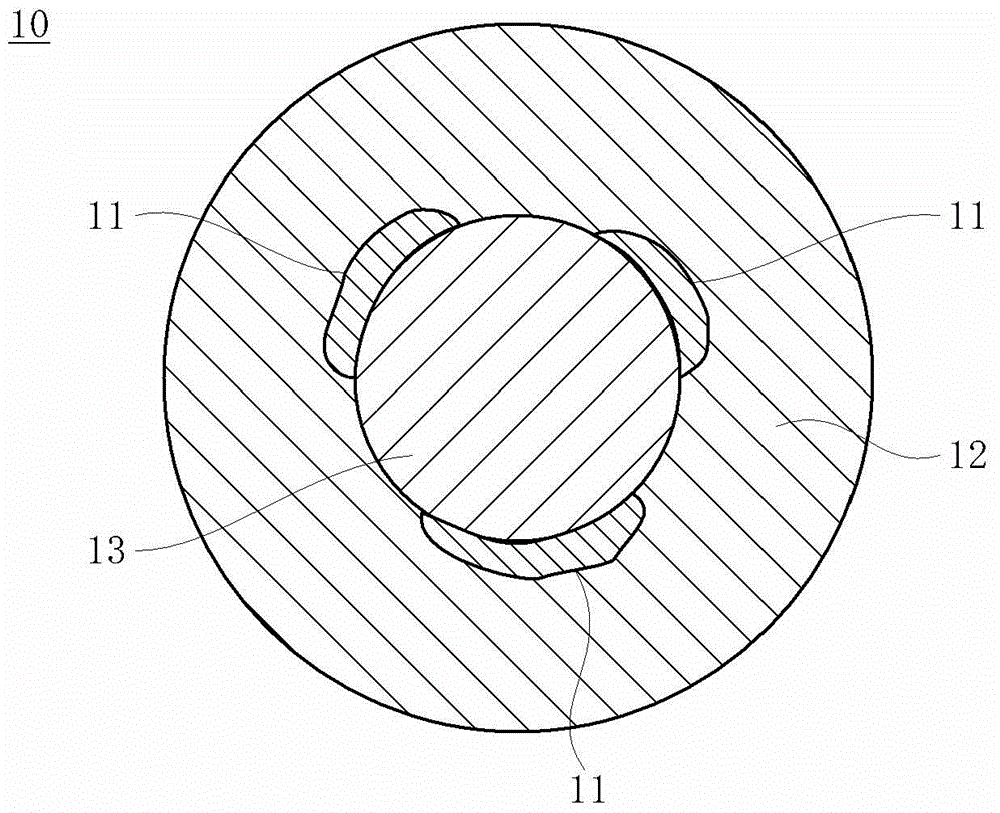

[0024] Solder paste is made by mixing flux containing solvent, rosin, thixotropic agent and activator with solder powder. Such as figure 1 As shown, the solder powder 10 has a central core 13, a first cladding layer 11 composed of an intermetallic compound of copper and tin covering a part of the central core 13, and a cladding core 13 and the first cladding layer. The composite powder of the second cladding layer 12 made of tin on the entire exposed surface of 11. And the central core 13 is a single structure comprised of the intermetallic compound of silver and tin in this embodiment. Here, as the intermetallic compound of copper and tin constituting the first cladding layer 11, Cu 3 Sn or Cu 6 sn 5 , as the intermetallic compound of silver and tin constituting the central core 13, Ag 3 Sn or Ag 4 Sn.

[0025] It is preferable that the average particle diameter of the said solder powder is 0.1-5 micrometers. Furthermore, the content of tin in the solder powder is pre...

no. 2 Embodiment approach >

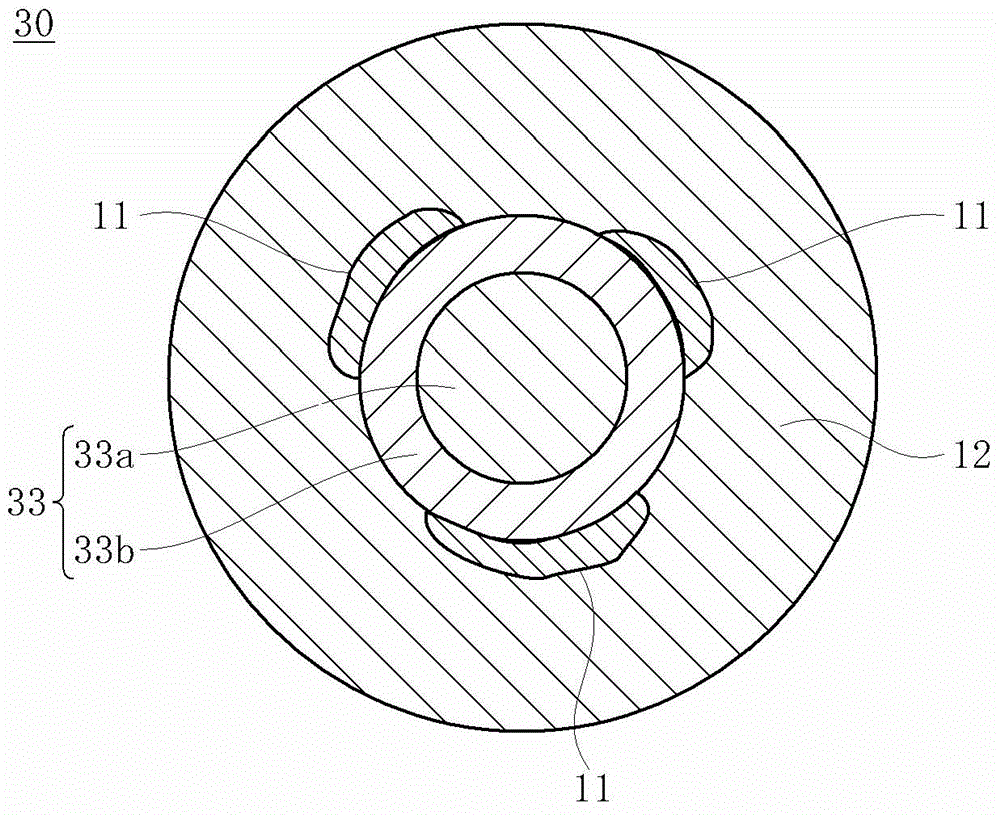

[0052] image 3 The second embodiment of the present invention is shown. image 3 neutralize figure 1 The same symbols denote the same components. In this embodiment, the central core 33 of the solder powder 30 has a double structure in which the entire silver 33a is covered with an inner core coating layer 33b made of an intermetallic compound of silver and tin. That is, the solder powder 30 has a central core 33 having a double structure, a first cladding layer 11 composed of an intermetallic compound of copper and tin covering a part of the central core 33, and a coating layer 11 covering the central core 33 and the first cladding layer. Composite powder of the second coating layer 12 made of tin on the entire exposed surface of the coating layer 11 . Here, Ag 3 Sn or Ag 4 Sn. Except for the above, the configuration is the same as that of the solder powder of the first embodiment. Furthermore, the solder paste has the same configuration as the solder paste of the fir...

Embodiment

[0057] Next, examples of the present invention will be described in detail together with comparative examples.

[0058]

[0059] Such as figure 1 As shown, first, a solder powder 10 (core-shell structure) having an average particle diameter of 0.1 μm is produced, which is a central core 13 having a single structure composed of an intermetallic compound of silver and tin, and a part of the central core 13 is covered. Composite powder of a first cladding layer 11 composed of an intermetallic compound of copper and tin, and a second cladding layer 12 composed of tin covering the central core 13 and the entire exposed surface of the first cladding layer 11 , and contain silver, copper, and tin in proportions of 3.0% by mass, 0.5% by mass, and 96.5% by mass, respectively. Next, 44.5% by mass of diethylene glycol monohexyl ether (solvent), 47.1% by mass of polymerized rosin (rosin), 3.0% by mass of hardened castor oil (thixotropic agent), and 0.4% by mass of diethylamine hydrobro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com