Device and method for removing oxide scales from hot rolled steel bands by using steel wire roller brush

An iron oxide scale and steel wire roll technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of social pollution, small use range, high use cost, avoid friction, ensure friction, improve clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The core of the present invention is to provide a device for removing iron scale from a hot-rolled steel strip by using a steel wire roller brush, which can make every part of the steel strip rub against the steel wire roller brush, greatly improving the effect of removing iron oxide scale. In addition, another core of the present invention is to provide a method for removing iron oxide scale from a hot-rolled steel strip by using a wire roller brush.

[0045] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

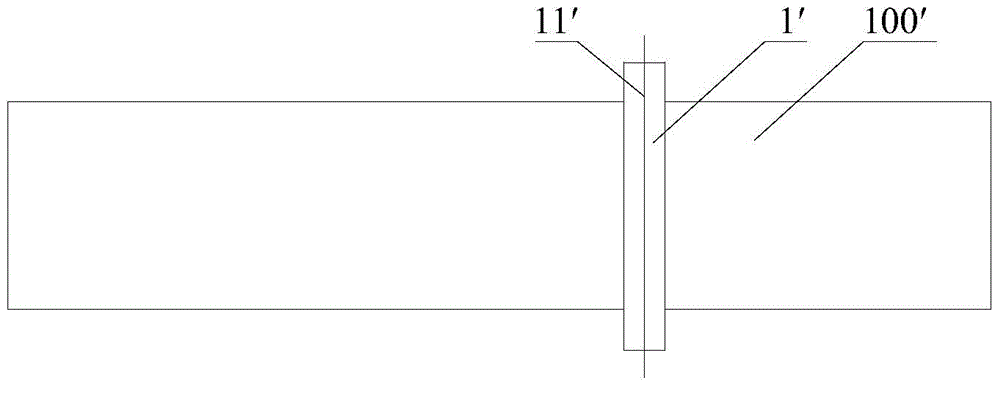

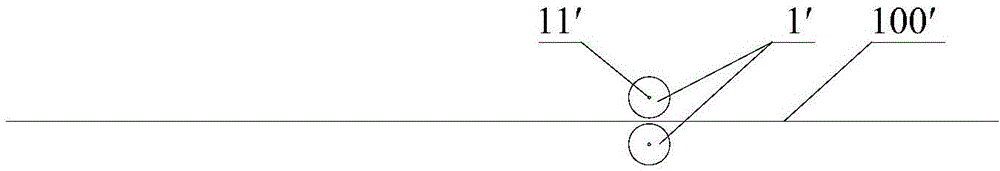

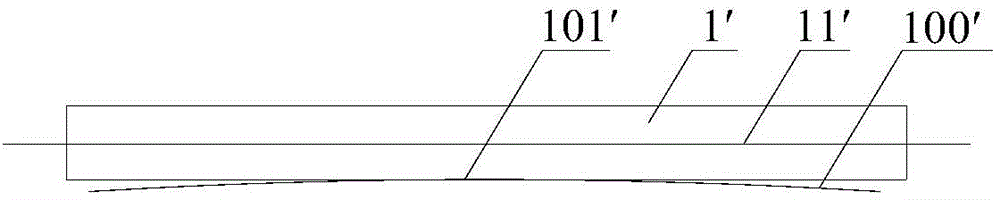

[0046] It should be noted that the orientation word "width direction" in this article refers to figure 1 , Figure 5-Figure 8 The left and right direction, the "above" and "below" in this article refer to figure 2 , Figure 5-Figure 8 It should be understood th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com