Preparation method of closed spatial curved surface structure casting core

A curved surface structure and closed technology, which is applied to casting molding equipment, cores, casting molds, etc., can solve problems such as inconsistency in the design requirements of space curved surfaces, deformation of the cavity in the core, etc., and achieve good high temperature resistance and high solubility , the effect of low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in conjunction with specific embodiments:

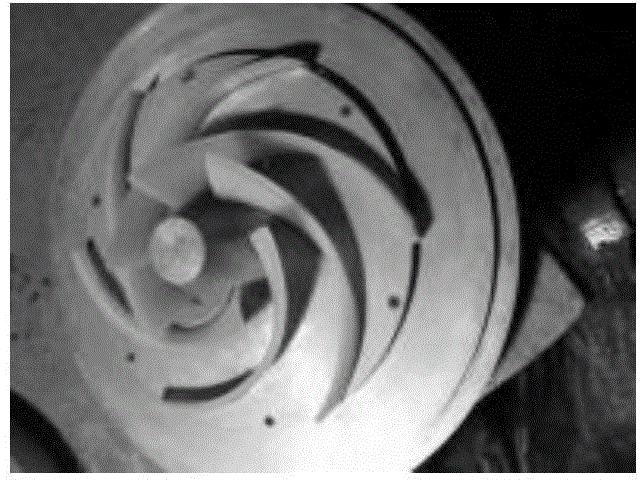

[0025] The closed space curved surface structure casting in this embodiment is an open-close hydraulic impeller, and its space curved surface structure is a blade. The core preparation method adopted includes the following steps:

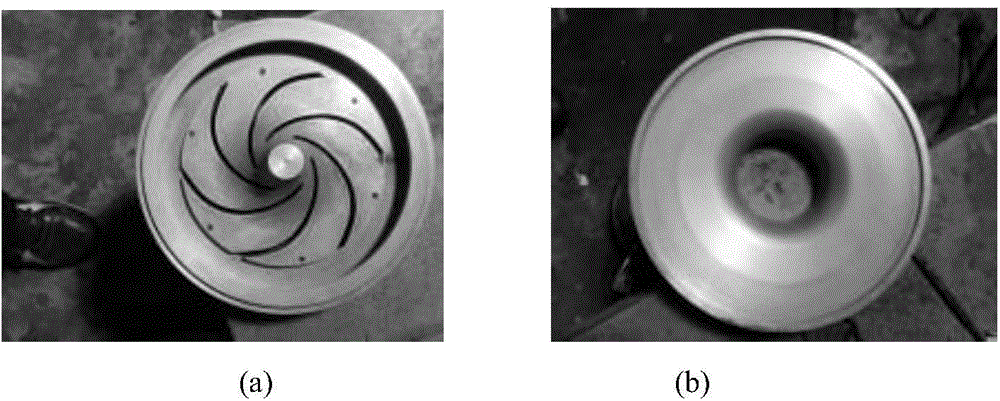

[0026] Step 1: Prepare a separate blade mold (used to prepare urea blades) and a core body core box (used to prepare resin sand cores). Core main core box such as figure 1 Shown.

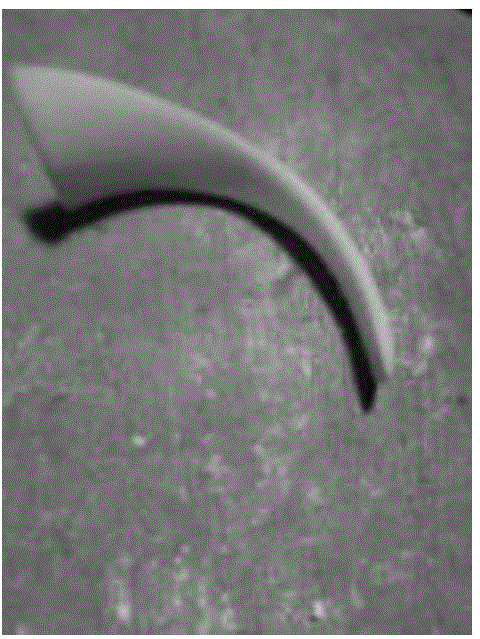

[0027] Step 2: Heat the urea to 150-160℃, pour the urea into the blade mold after completely melted, cool for 30-60 seconds, open the mold after the urea is solidified, take out the urea blade, and trim it to obtain a urea blade that meets the requirements of curved surface shape . Such as figure 2 Shown.

[0028] Step 3: According to the structural requirements of the open and closed hydraulic impeller, fix the six urea blades on the lower half of the main core box, such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com