Conical laser intensity testing device and testing method

A test device and laser technology, applied in the field of optics, can solve problems such as large influence, difficult adjustment, long time-consuming, etc., and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

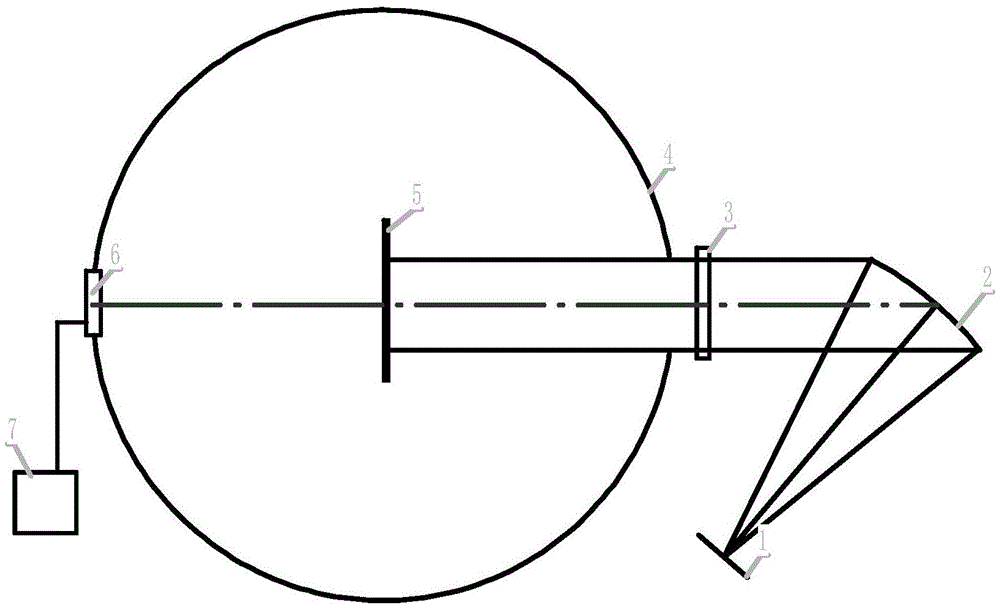

[0019] see figure 1 , including a fixed focus mask 1 , a collimating mirror 2 , an attenuation plate 3 , a scattering plate 5 , an integrating sphere receiver 4 , a power meter probe or an energy meter probe 6 and a display device 7 . The fixed focus cover 1 is arranged at the focal plane of the collimating mirror 2; the attenuating plate 3 and the diffusing plate 5 are successively arranged on the optical path where the reflected light formed after being reflected by the collimating mirror 2; the attenuating plate 3 and the diffusing plate 5 are respectively arranged on The outside and inside of the integrating sphere receiver 4; the power meter probe or the energy meter probe 6 is arranged on the side wall of the integrating sphere receiver 4; the display device 7 is connected with the power meter probe or the energy meter probe 6.

[0020] The fixed focus cover is provided with a small hole; the center of the small hole of the fixed focus cover coincides with the axial focu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com