Preparation method of high-carbon stainless steel standard sample

A technology of stainless steel and standard samples, which is applied in the field of preparation of high-carbon stainless steel standard samples, can solve problems such as poor uniformity between blocks, increased demand, and small sampling volume of control samples, so as to achieve high practical value, reduce preparation costs, and increase The effect of sample size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Present embodiment is the preparation method of 304 series high-carbon stainless steel standard sample,

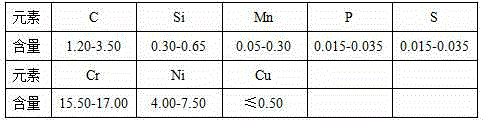

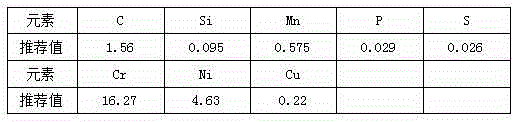

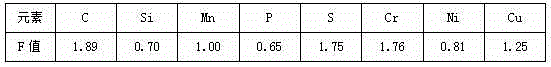

[0037] Table 1: Chemical composition range table (%)

[0038]

[0039] The data in the above table should be the general requirements for 304 series stainless steel,

[0040] The steps of this embodiment are as follows:

[0041] Design of casting model→baking of model and ladle→component selection→casting process control→demoulding→physical performance testing→sample processing→chemical composition uniformity test→fixed value analysis→determination of effective height, specifically including the following contents:

[0042] 1. Design of casting model:

[0043] The mold is made of pure copper, and the mold is made into 4 units with a water tank cooling system by copper-steel welding method, and then combined into a whole by the molding process to realize simultaneous casting.

[0044] 2. Baking of the model

[0045] After cleaning the used model, bake it in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com