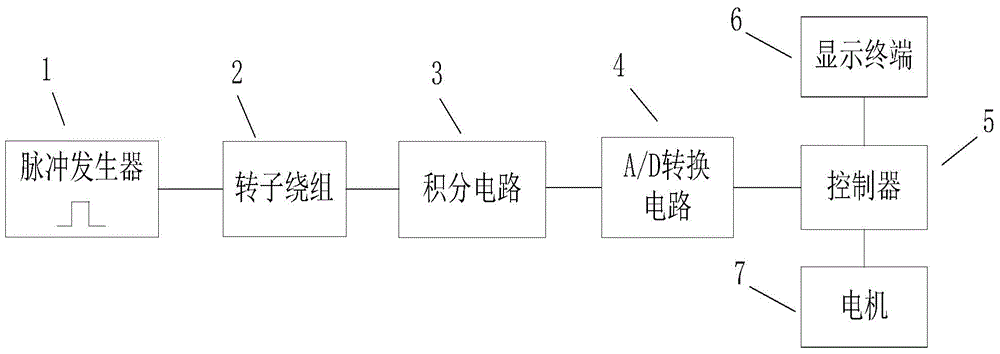

System and method for detecting defects of micromotor rotor windings

A rotor winding and defect detection technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of small motor winding detection equipment, can not reduce the product rejection rate, find rotor winding faults, etc., to eliminate artificial interference. , the detection speed is fast, the effect of reducing the sampling frequency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] In conjunction with the examples, the operation process of the detection method of the present invention is described.

[0059] Select a rotor winding with a diameter of 7mm, a winding wire diameter of 0.13mm, a single-phase 18 turns, and a 5-phase (5 commutator segments) for testing. The rotors include normal rotors, single-phase 3-turn short-circuit rotors, broken wire rotors and virtual welded rotors. .

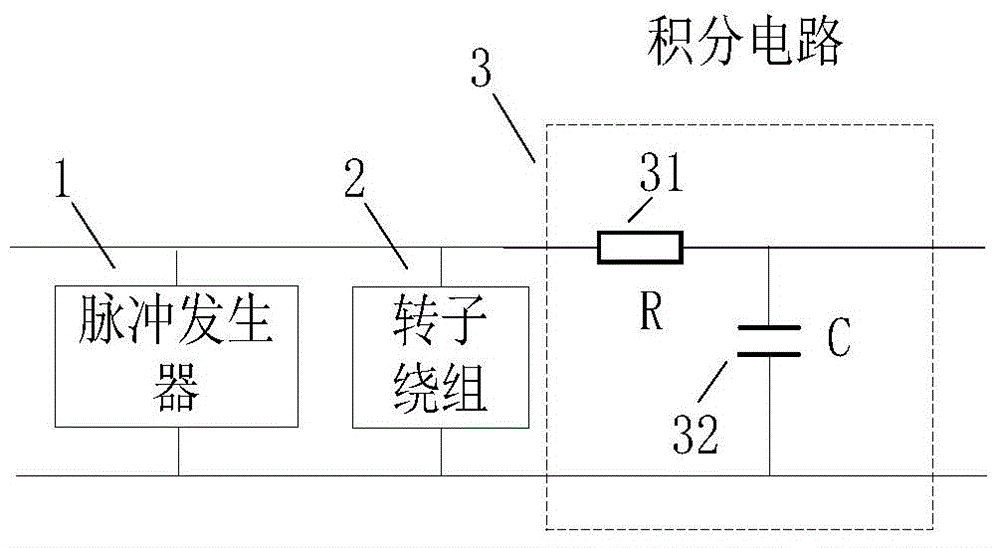

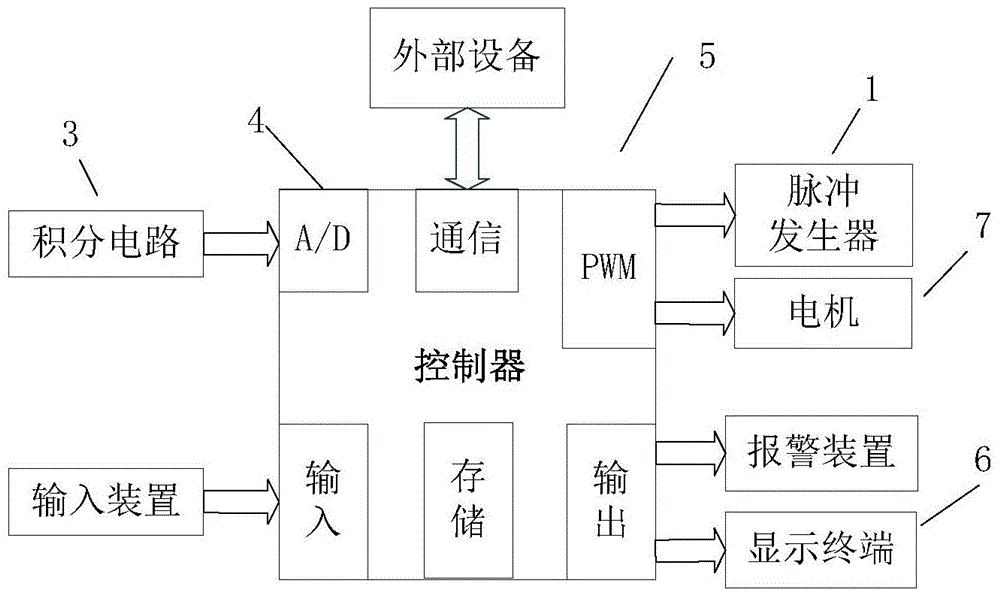

[0060] Operation steps: S1, pulse generator 1 generates a 12V square wave with a duty cycle of 50% and a frequency of 100kHz and loads it on the rotor winding 2;

[0061] S2, the controller 5 controls the motor 7 to rotate 72°;

[0062] S3, the A / D converter 4 collects the voltage of the integrating circuit 3, and transmits it to the controller, and counts once;

[0063] S4. Repeat steps S2-S34 times to complete the sampling of the 5-phase coils of the rotor winding, and the controller performs a data processing program to distinguish the state of the rotor windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com