Home-made automatic embedded computer system and display card driving method thereof

A technology driven by an embedded computer and graphics card, applied in the direction of program control devices, etc., to achieve strong performance, improve portability, improve human-computer interaction performance and graphics display and control performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be described in further detail below in conjunction with the accompanying drawings.

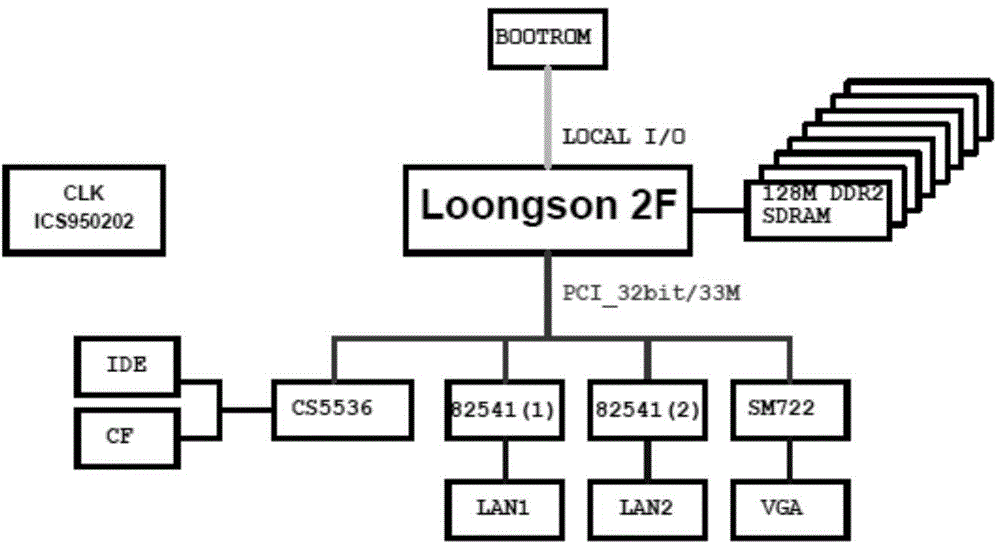

[0047] A domestic self-made embedded computer system and a graphics card driving method thereof, including a Loongson 2F central processing unit, an SM722 display chip, and the SM722 display chip communicates with the Loongson 2F through a 32-bit 33MHz / 66MHz PCI bus.

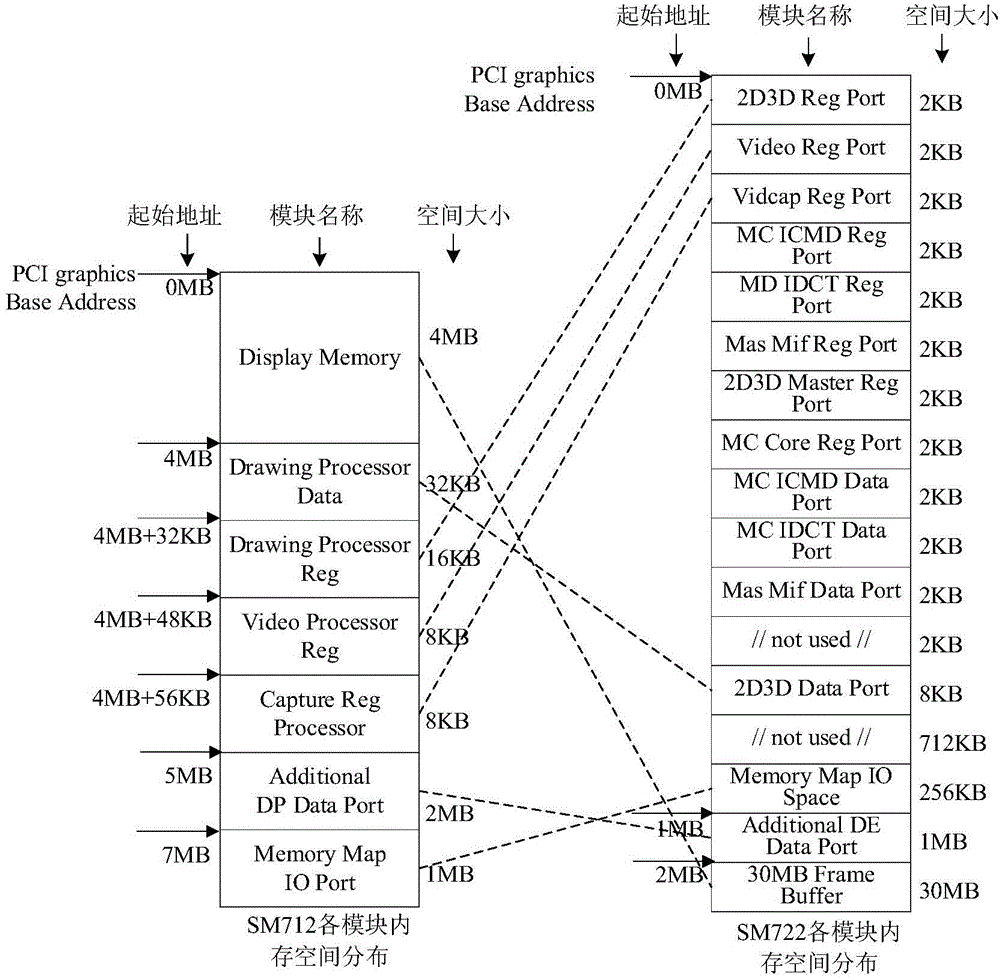

[0048] To realize the Loongson 2F embedded computer system equipped with the SM722 display chip, it is necessary to completely independently solve the three major tasks of hardware design, firmware driver and operating system driver development. Refer to the SM722 hardware design guidebook and reference design released by Silicon Motion to complete the hardware design, and then use the existing pmon driver (provided by Godson Technology Co., Ltd., no detailed version number) and Linux graphics driver (Godson Technology Co., Ltd.) that supports SM712 Provided by the company, such as the kernel ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com