A kind of preparation method of terbinafine hydrochloride microcapsule antibacterial agent for shoes

A technology of terbinafine hydrochloride and microcapsules, applied in botany equipment and methods, fungicides, chemicals for biological control, etc., can solve the problems of poor antibacterial persistence, troublesome use, and inability to achieve durable antibacterial, etc. It achieves the effect of improving water washing resistance, high safety, and green and environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

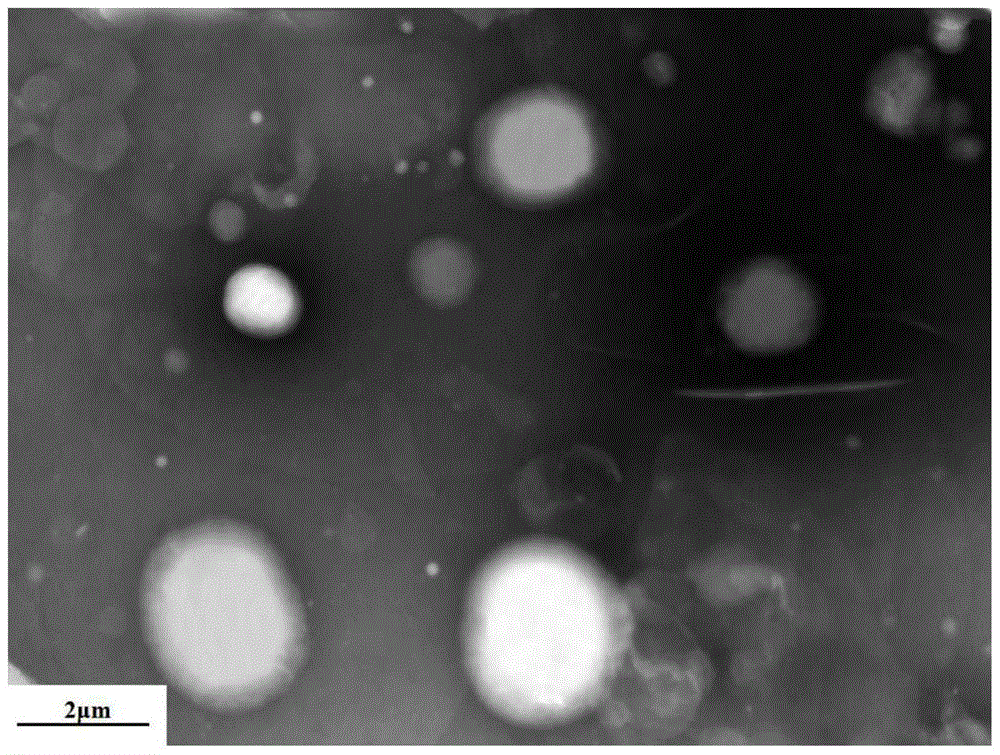

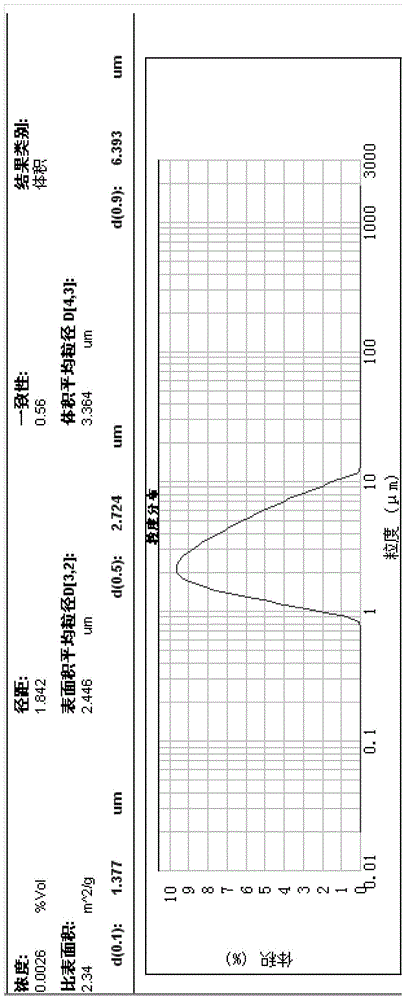

Image

Examples

Embodiment 1

[0016] Step 1: configuration mass concentration is 2% chitosan aqueous solution respectively (chitosan obtains through degradation, and its molecular weight is about 3000), mass concentration is 2% gum arabic aqueous solution, mass concentration is 2% terbinaline hydrochloride Fen cream aqueous solution;

[0017] Step 2: the chitosan aqueous solution, gum arabic aqueous solution and terbinafine hydrochloride aqueous solution of step 1 gained are mixed according to the ratio of core wall 2:1, wall material ratio (chitosan / gum arabic) 1:1, mix The sequence is to first mix the gum arabic aqueous solution and the terbinafine hydrochloride solution, then add the chitosan solution, place the beaker in a constant temperature water bath, and stir for 15 minutes at a temperature of 40°C and a stirring speed of 400r / min;

[0018] Step 3: Use sodium hydroxide with a molar concentration of 0.1mol / L to adjust the pH value of the mixed solution obtained in step 2 to 5 to cause complex coace...

Embodiment 2

[0022] Step 1: configuration mass concentration is 2% chitosan aqueous solution respectively (chitosan obtains through degradation, and its molecular weight is about 3000), mass concentration is 2% gum arabic aqueous solution, mass concentration is 2% terbinaline hydrochloride Fen cream aqueous solution;

[0023] Step 2: the chitosan aqueous solution, gum arabic aqueous solution and terbinafine hydrochloride aqueous solution of step 1 gained are mixed according to the ratio of core wall ratio 1:1, wall material ratio (chitosan / gum arabic) 1:1, mix The sequence is to first mix the gum arabic aqueous solution and the terbinafine hydrochloride solution, then add the chitosan solution, place the beaker in a constant temperature water bath, and stir for 15 minutes at a temperature of 50°C and a stirring speed of 500r / min;

[0024] Step 3: Use sodium hydroxide with a molar concentration of 0.1 mol / L to adjust the pH value of the mixed solution obtained in step 2 to 5 to cause a comp...

Embodiment 3

[0028] Step 1: configuration mass concentration is respectively the chitosan aqueous solution of 3% (chitosan obtains through degradation, and its molecular weight is about 3000), mass concentration is 3% gum arabic aqueous solution, mass concentration is 3% terbinaline hydrochloride Fen cream aqueous solution;

[0029] Step 2: the chitosan aqueous solution, gum arabic aqueous solution and terbinafine hydrochloride aqueous solution of step 1 gained are mixed according to the ratio of core wall ratio 1:1, wall material ratio (chitosan / gum arabic) 1:1, mix The sequence is to first mix the gum arabic aqueous solution and the terbinafine hydrochloride solution, then add the chitosan solution, place the beaker in a constant temperature water bath, and stir for 15 minutes at a temperature of 40°C and a stirring speed of 400r / min;

[0030] Step 3: Use sodium hydroxide with a molar concentration of 0.1mol / L to adjust the pH value of the mixed solution obtained in step 2 to 4.5 to caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com