Automatic airing equipment for high-quality white tea

A high-quality, white tea technology, applied in the direction of pre-extraction tea processing, etc., can solve the problems of low-quality, continuous and low-automatic white tea, and achieves improved tea quality, fast sliding back and forth, and improved automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

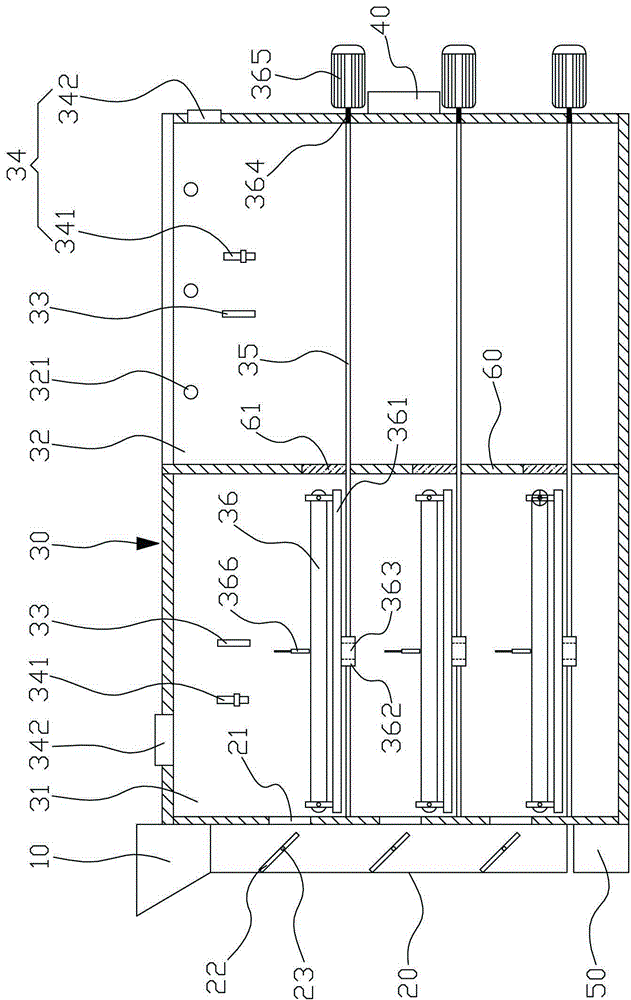

[0026] A high-quality white tea automatic drying equipment, refer to figure 1 , including a feed hopper 10, a feed channel 20, a tea room 30 and a control box 40. Wherein, the tea-drying room 30 is divided into a left storage room 31 and a right artificial light tea-drying room 32 by a partition 60 , and the feeding channel 20 is attached to the outer wall of the storage room 31 and arranged along the vertical direction. The bottom end of the feed hopper 10 is connected to the upper end of the feed channel 20, and the bottom end of the feed channel 20 is open, and a collection device 50 for collecting the dried white tea is provided below the feed channel 20. The top wall of the artificial light tea drying room 32 is made of transparent material, such as glass, transparent plastic, etc., to ensure that there is enough sunlight to shine through the top wall into the artificial light tea drying room 32 to dry the white tea. The artificial light drying tea room 32 is also provid...

Embodiment 2

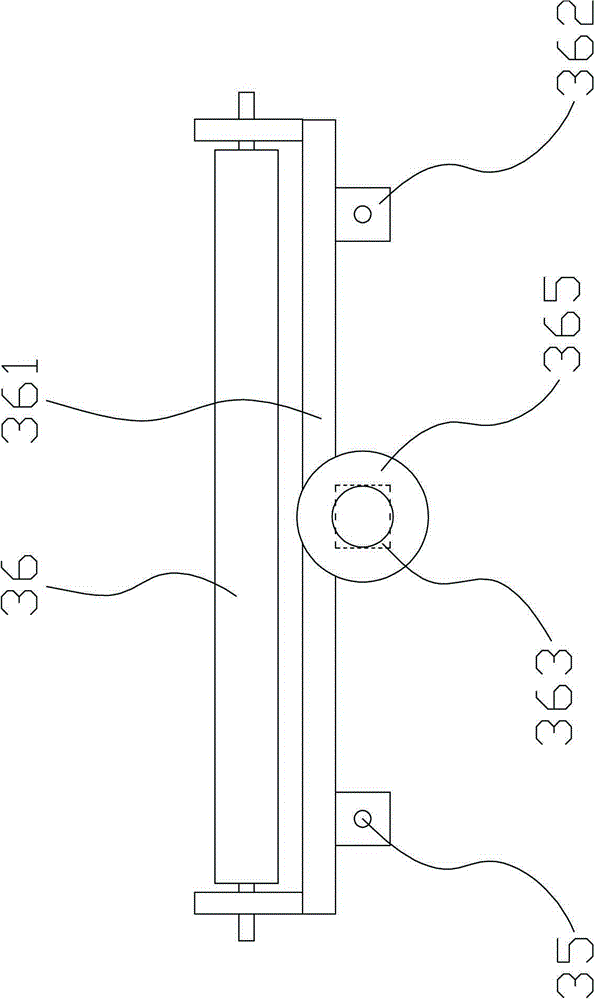

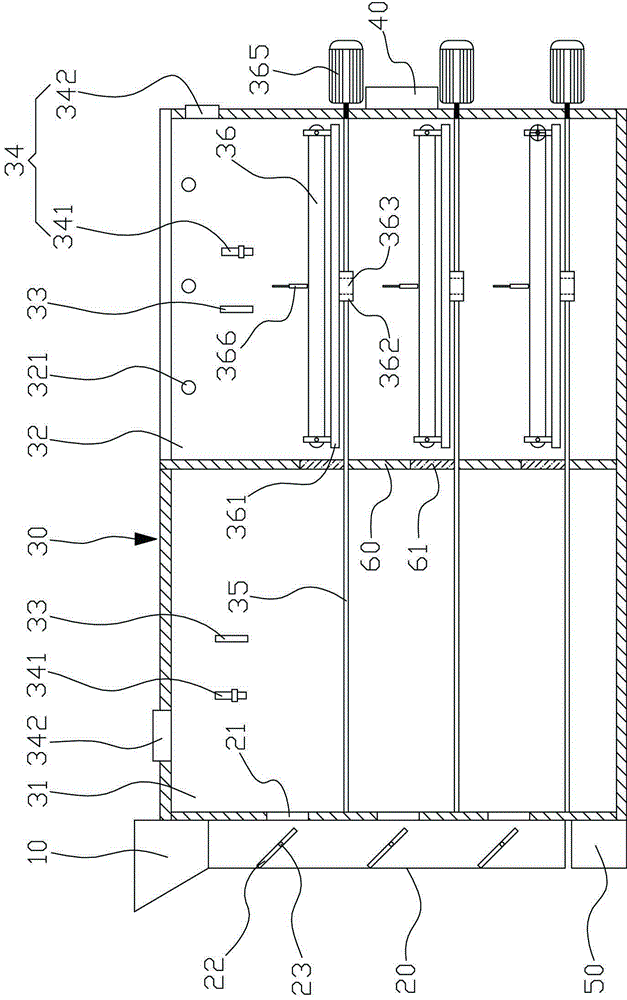

[0032] This embodiment is basically the same as Embodiment 1, the difference is that the conveyor belt 36 slides back and forth on the guide rail 35, the guide rail 35 of this structure is a track for the rollers to walk around, and a support frame is also fixed below the conveyor belt 36 361, the bottom of the support frame 361 is provided with a plurality of rollers 362, the front and rear ends of the support frame 361 are connected with an endless chain 363, and the two ends of the endless chain 363 are respectively provided with a driving wheel 364 and a driven wheel 365, wherein the driving wheel 364 Driven by a motor (not shown in the figure) to rotate so that the support frame 361 moves back and forth on the guide rail.

[0033] Of course, the conveyor belt can also be manually pushed to move between the material storage chamber 31 and the tea drying chamber 32 under artificial light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com