A Worktable Mechanism of Compound Machining Center

A composite processing and workbench technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as increasing labor intensity, reducing work efficiency, and affecting processing accuracy, achieving reasonable structural design and ensuring lubrication effects. , The effect of smooth oil circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

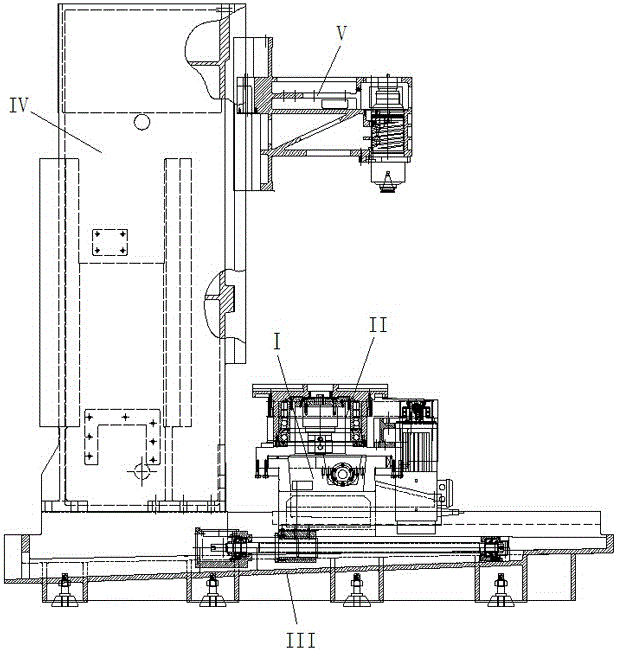

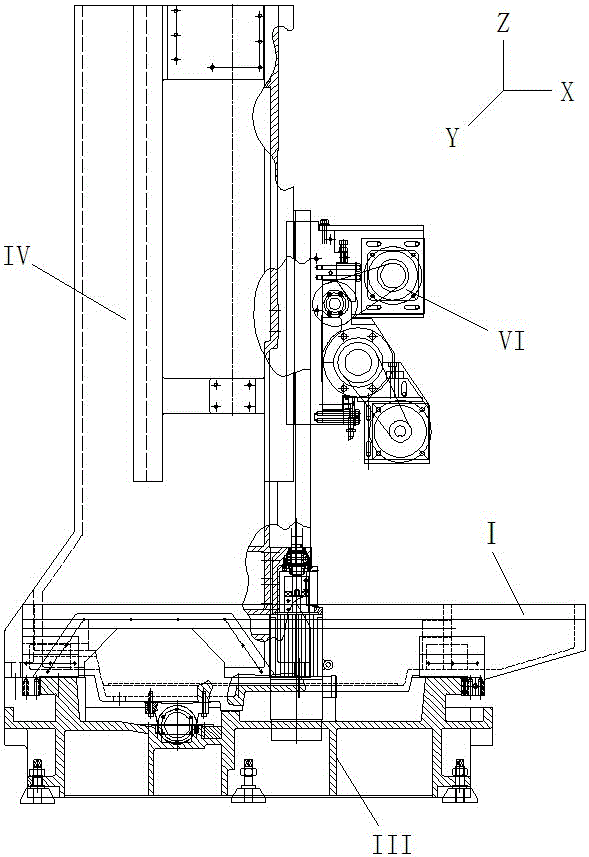

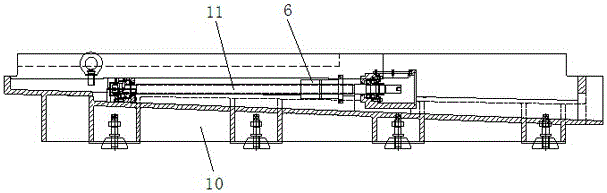

[0048] see Figure 1 to Figure 23 , the three coordinate axes of the X-axis, Y-axis, and Z-axis of the spatial coordinate system where the composite machining center is applied are set as follows: from the front of the composite machining center, the X-axis is placed horizontally, pointing to The left and right direction; the Y axis is placed horizontally, pointing to the front and rear directions; the Z axis is placed vertically, pointing to the up and down direction. In this application document, the X-axis, Y-axis, and Z-axis all refer to the coordinate axes set above.

[0049] The composite machining center to which the present invention is applied includes bed components and column components.

[0050] The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com