Ampoule bottle opener

A bottle opener and ampoule technology, which is applied in the field of medical bottle openers, can solve the problems of injury of medical staff, contamination of glass fragments, contamination of medicinal liquid, etc., and achieves the effects of low production cost, good safety and simple structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

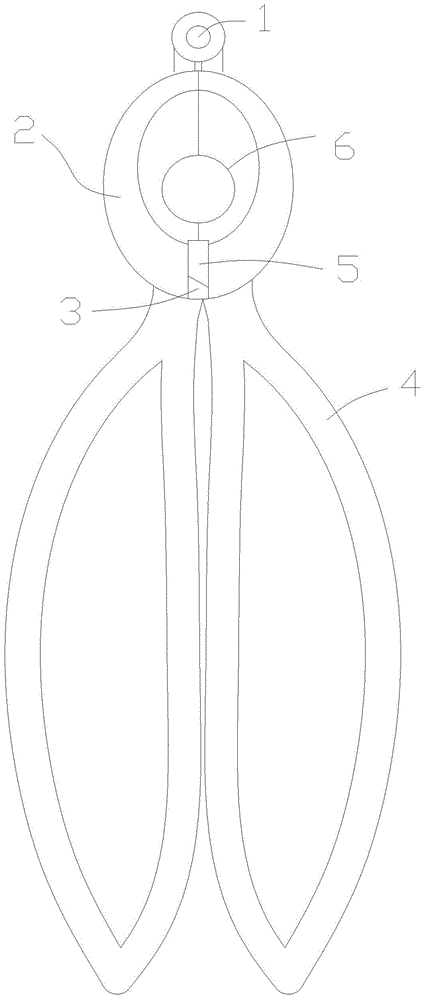

[0034] Example 1, such as Figure 1-5 As shown, (inclined push mode, apply breaking force to the bottle body)

[0035] An ampoule bottle opener, comprising a bottle body clamping part 2, the bottle body clamping part 2 is composed of two left and right split bodies that are combined, the upper ends of the two split bodies are connected by a pin shaft 1, and the lower ends of the two split bodies are respectively A handle 4 is connected, and an ampoule clamping cavity is provided in the middle of the bottle body clamping part 2. The middle part of the ampoule clamping cavity is provided with a bottle curved neck clamping part 6, and the ampoule clamping cavity is clamped by the bottle curved neck Divided into two upper and lower cavities, the cavity below the curved neck clamping part 6 of the bottle body is the bottle body clamping cavity 8, and the cavity above the curved neck clamping part 6 of the bottle body is the ampoule nipple breaking cavity 7 ;

[0036] The upper pa...

Embodiment 2

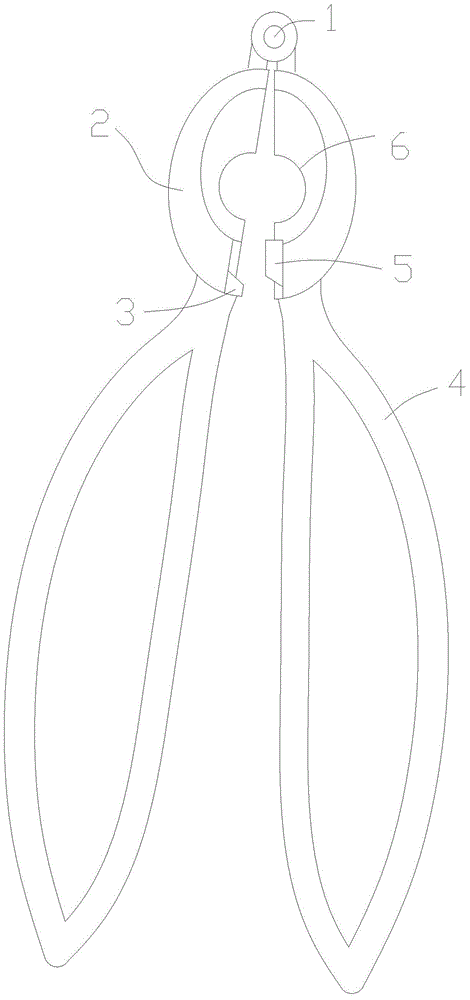

[0040] Embodiment 2, (worm gear and worm transmission mode applies breaking force to the bottle body)

[0041] Such as Figure 6 As shown, an ampoule bottle opener has the same structure of the bottle clamping part and the handle as in Embodiment 1, but the difference is the structural design of the bottle breaking part and the bottle breaking driving part.

[0042] Including the bottle body clamping part 2, the bottle body clamping part 2 is composed of two left and right split parts, the upper ends of the two split parts are connected by rotation through the pin shaft 1, and the lower ends of the two split parts are respectively connected with a handle 4, the bottle body There is an ampoule clamping cavity in the middle of the clamping part 2, and the bottle curved neck clamping part 6 is arranged in the middle of the ampoule clamping cavity, and the ampoule clamping cavity is divided into two upper and lower cavities by the bottle curved neck clamping part .

[0043]The u...

Embodiment 3

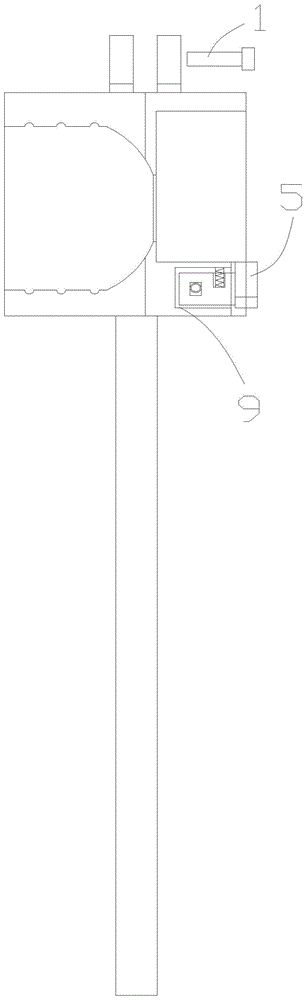

[0045] Embodiment 3, (electric mode, applies breaking force to bottle body)

[0046] Such as Figure 7 As shown, the structure of the electric ampoule bottle opener is the same as that of the embodiment 1, except for the structure design of the bottle breaking part and the bottle breaking driving part.

[0047] Including the bottle body clamping part 2, the bottle body clamping part 2 is composed of two left and right split parts, the upper ends of the two split parts are connected by rotation through the pin shaft 1, and the lower ends of the two split parts are respectively connected with a handle 4, the bottle body There is an ampoule clamping cavity in the middle of the clamping part 2, and the bottle curved neck clamping part 6 is arranged in the middle of the ampoule clamping cavity, and the ampoule clamping cavity is divided into two upper and lower cavities by the bottle curved neck clamping part ;

[0048] The upper part of the end where the bottle clamping part 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com