Antiscalant agent for water-in-oil system in high-temperature oilfield environment, its preparation method and application

A technology of high temperature environment, anti-scaling agent, applied in water pollutants, mining wastewater treatment, descaling and water softening, etc., can solve the problem of anti-scaling of steam heaters in few oil fields, achieve good biodegradation performance, unique inhibition effect, effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

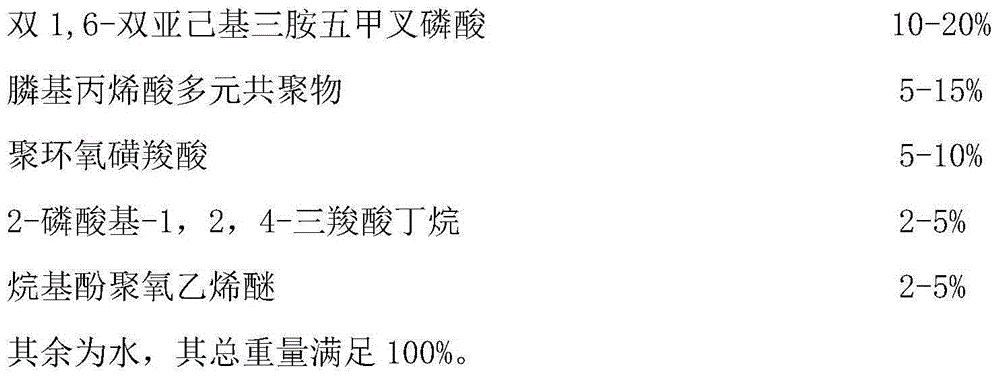

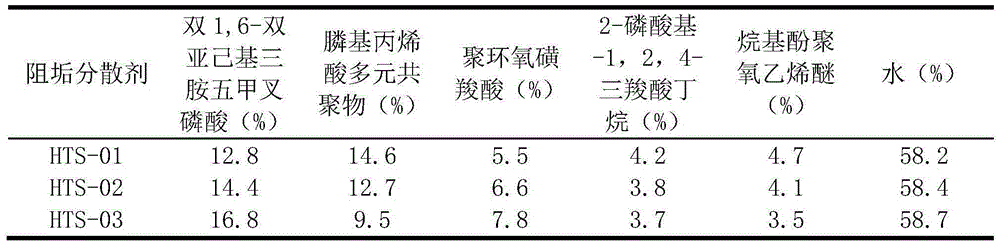

[0020] Preparation of antiscalant agent: prepare an antiscalant agent suitable for water-in-oil system in oil field ultra-high temperature environment according to the weight ratio of the components described in Table 1, and add the commercially available liquid single agent bis-1,6-bis-hexamethylene triamine penta Methylidene phosphoric acid, phosphinoacrylic acid multi-polymer, polyepoxysulfonic acid, 2-phospho-1,2,4-tricarboxylic butane, stir evenly, adjust the pH value to 7 with 40% sodium hydroxide, Stir for 20 minutes, cool to room temperature, add emulsifier alkylphenol polyoxyethylene ether, calculate the water consumption, add a certain amount of water to make the active ingredient of the agent 40%, stir for 15 minutes, and obtain the finished oilfield antiscaling agent.

[0021] Table 1 prepares each single agent pure product weight percent example of antiscaling agent

[0022]

[0023]

[0024] The obtained antiscalant drug names are HTS-01, HTS-02, HTS-03, HT...

Embodiment 2

[0026] Add 100mg / L of HTS-01, HTS-02, HTS-03, HTS-04, HTS-05 to the oil-water mixture with water content of 10% and 20% respectively, after fully shearing and emulsifying, separate and measure water The effective concentration of antiscalant and dispersant in the phase.

[0027] Table 2 Dispersibility of antiscalant and dispersant in oil-water phase

[0028]

Embodiment 3

[0030] During the experiment, the oil-water mixture samples in the oilfield were prepared or the oil-water mixture was collected on the oilfield site, and the high-temperature and high-pressure reactor was used to simulate the temperature of the heat exchange interface of the on-site steam heater device and the pressure of the oil-water mixture, and the water-phase scaling of the oil-water mixture in the oilfield was investigated. For the experiment, the experimental process is shown in the attached figure figure 1 .

[0031] Table 3 The quality of oilfield produced water with calcium sulfate scaling tendency in laboratory configuration

[0032]

[0033] Put the prepared aqueous solution in the high temperature and high pressure simulated steam heater device in the laboratory, heat it at a constant temperature of 180°C for 2 hours, take out the solution after cooling, detect the remaining calcium ion concentration at this time, calculate the scale inhibition rate of the ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com