Road finishing machine with pushing device

A technology of a pushing device and finishing machine, which is applied in road repairing, accessories for easy driving, roads, etc., and can solve the problems that road finishing machines require a large space, high manufacturing cost, and difficult to refit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

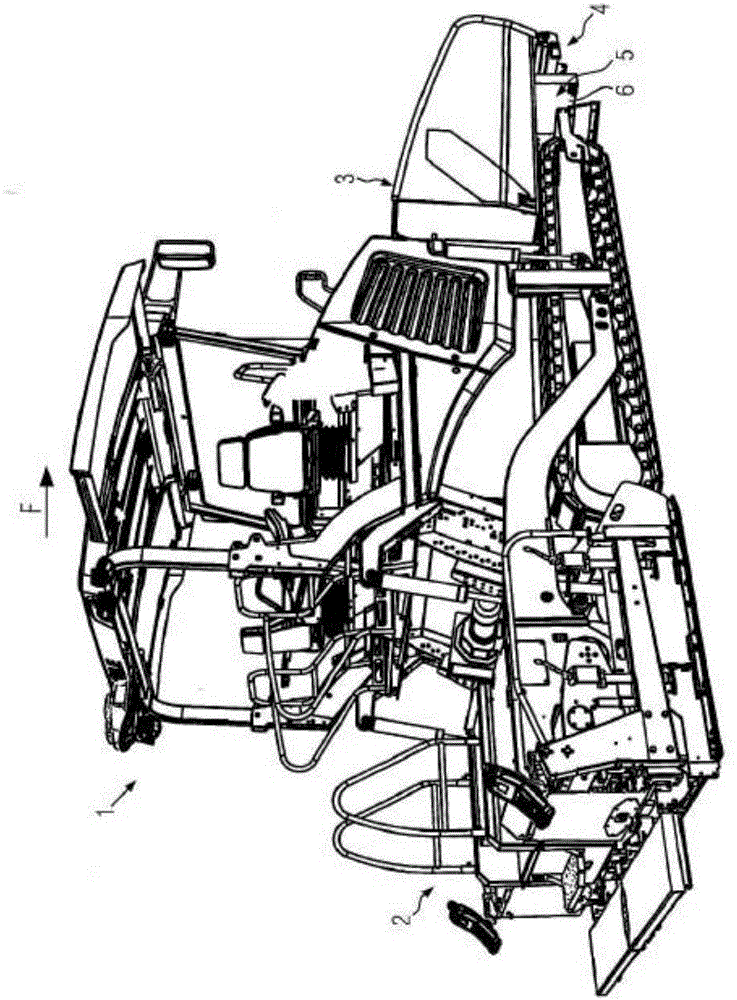

[0041] figure 1 A road finishing machine 1 is shown with a screed 2 and a material hopper 3 arranged in front (seen in the paving direction F) for receiving the paving material. The pushing device 4 according to the present invention is arranged in front of the material hopper 3 . The pushing device 4 is installed at the chassis 5 of the road finishing machine 1 . Specifically, the pushing device 4 is fixed to the cross member 6 of the chassis 5 .

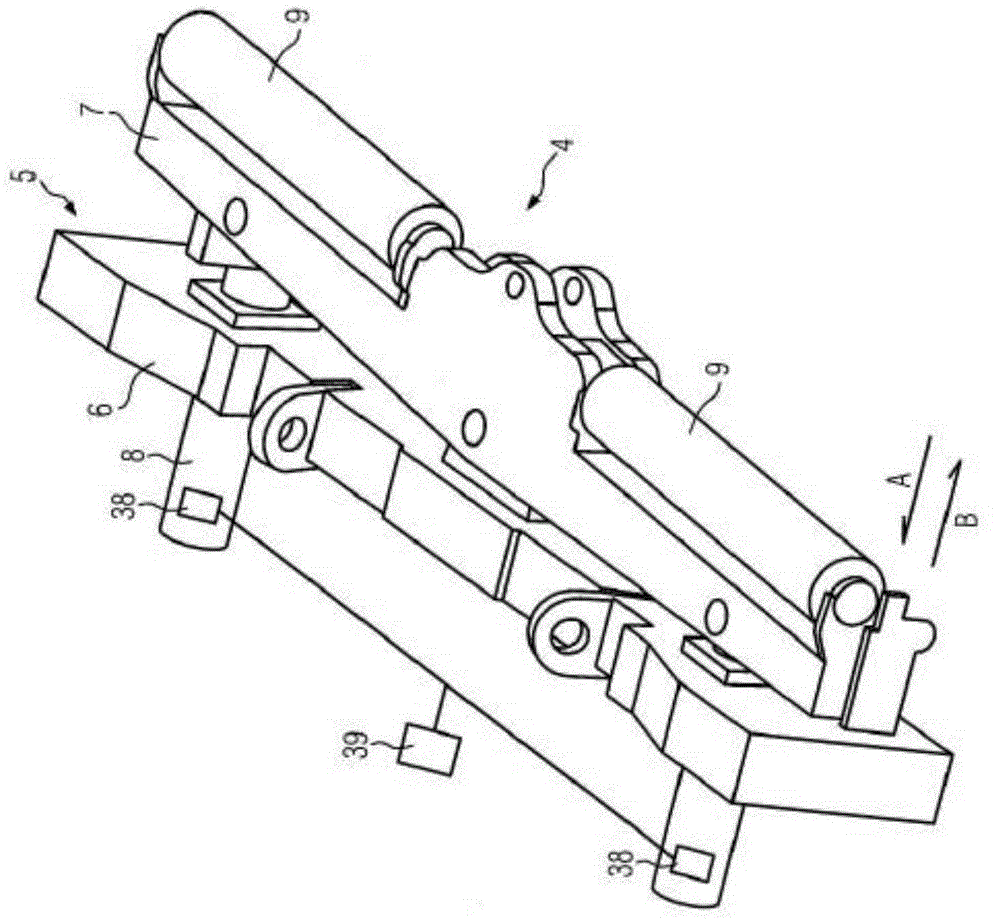

[0042] figure 2 The pushing device 4 is shown detached from the road finishing machine 1 in an enlarged perspective representation. The pusher 4 has a docking assembly 7 and first and second absorber units 8 . Two absorber units 8 are fastened to the cross member 6 of the chassis 5 . The docking assembly 7 is mounted so as to be movable relative to said cross member 6 of the chassis 5 . The docking assembly 7 is movable towards and away from the cross member 6 . If the load L acts on the butt assembly 7 from the front on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com