Prestressed tension device and method for fiber sheet

A fiber sheet and tensioning device technology, which is applied in the processing of building materials, building maintenance, construction, etc., can solve the problems of difficult construction, low investment cost, complex structure, etc., and achieve simple construction methods and high tension. Accurate control, flexible installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

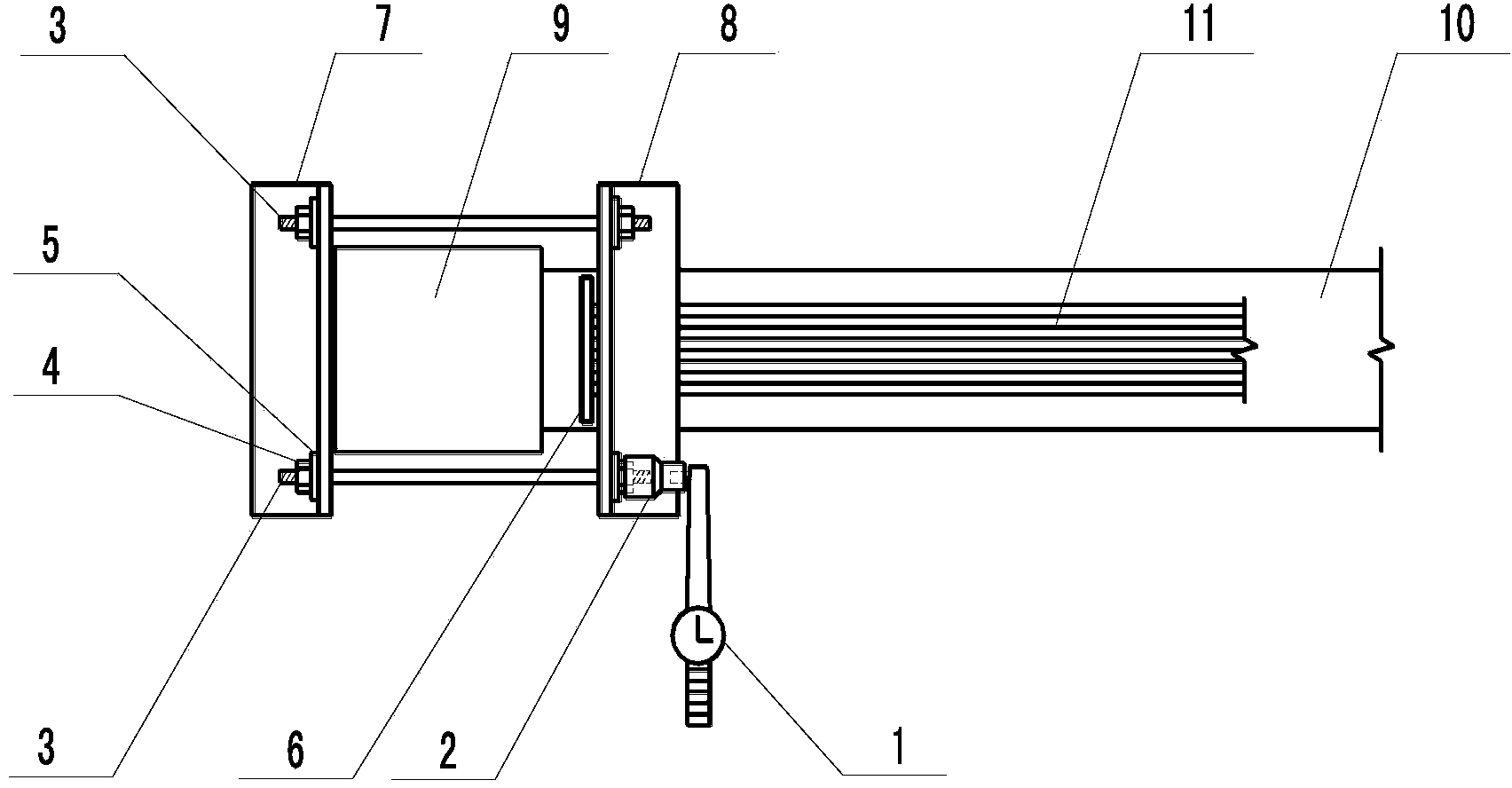

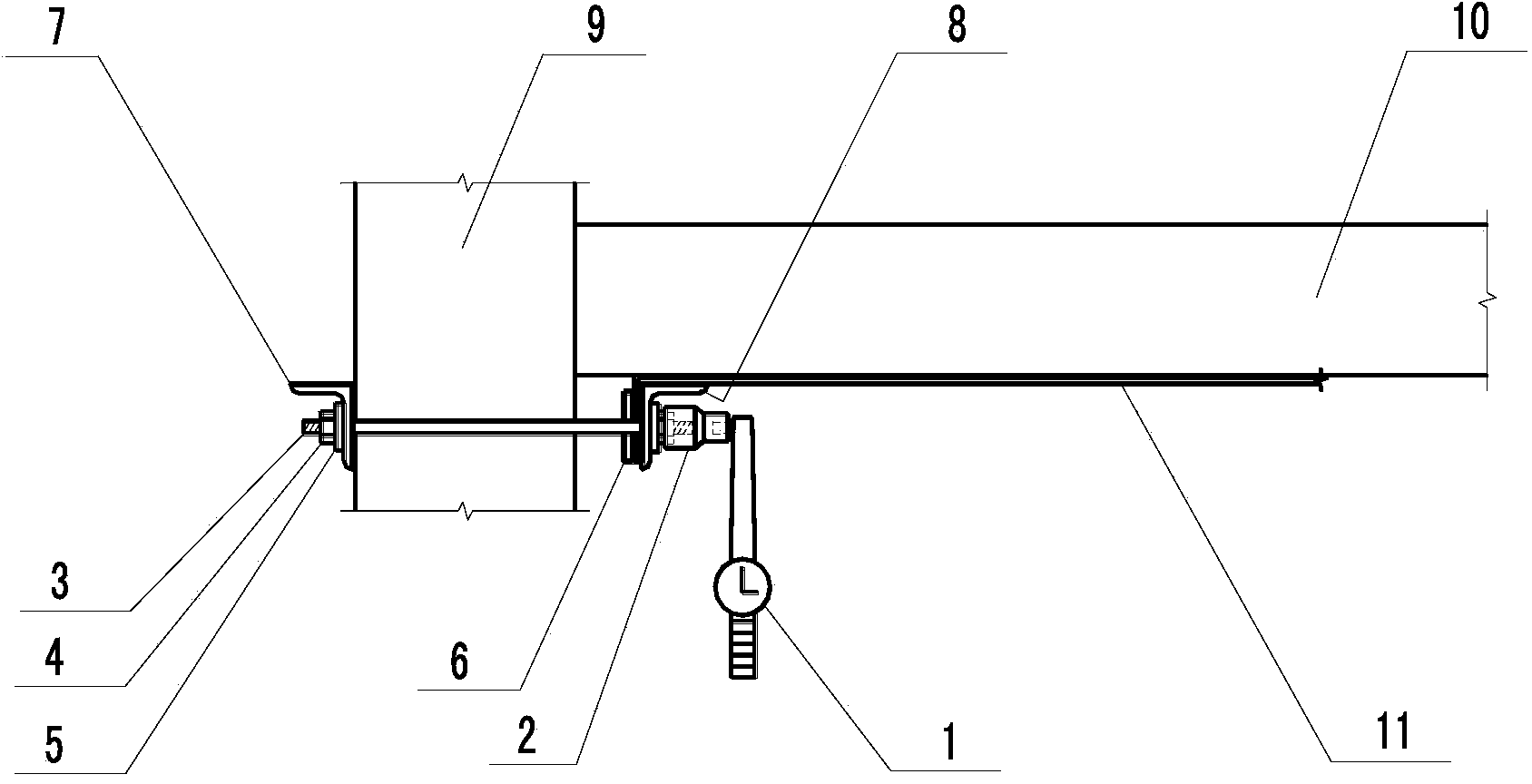

[0028] See Figure 1-Figure 2 , is a structural schematic diagram of the device of the present invention, a prestressed tensioning device for fiber sheets according to the present invention, including an adjustable support, a digital display torque wrench 1, a sleeve 2 and a clamping plate 6, the The adjustable support is composed of seat one 7 and seat two 8 connected by screw 3 and nut 4. The clamping plate 6 clamps and fixes the fiber sheet 11 on one side of the adjustable support. 1 Cooperate with the sleeve 2 and adjust the nut 4 to change the distance between the seat bodies 7 and 8 to stretch the fiber sheet 11.

[0029] The base body 1 7 and base body 2 8 are made of angle steel and arranged opposite to each other, and at least one set of screw rods 3 and nuts 4 are fixedly connected to each other at both ends.

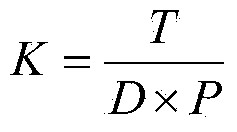

[0030] Based on the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com