Metallic reflection heat preservation cover and manufacturing method thereof

A technology of metal reflection and insulation layer, applied in the direction of heat preservation, pipeline protection, pipeline protection through heat insulation, etc., can solve problems such as skin itching or respiratory allergies, poor waterproof performance, poor compressive and flexural strength, etc. To achieve the effect of convenient and reliable use, beautiful appearance and reduced harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

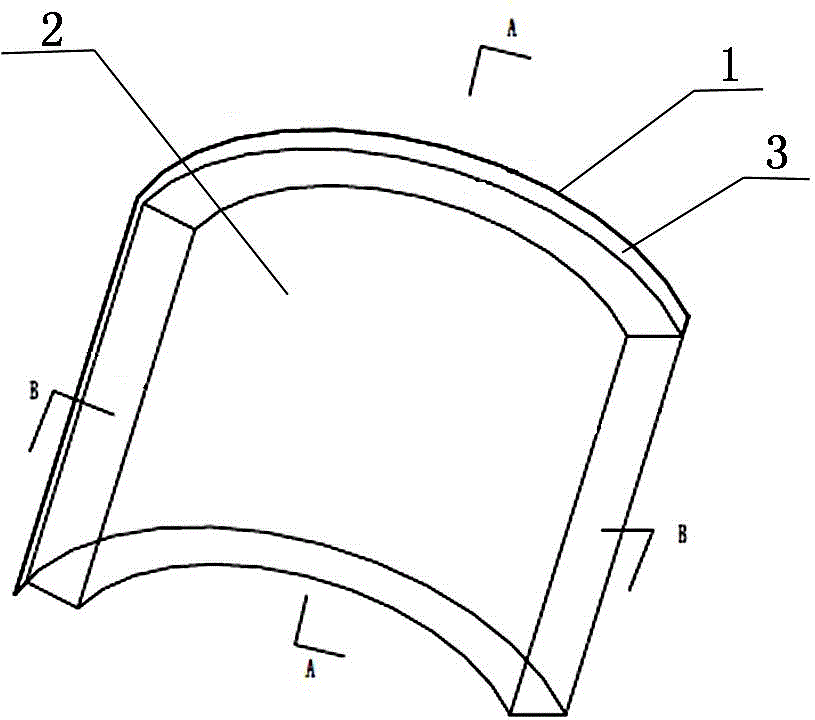

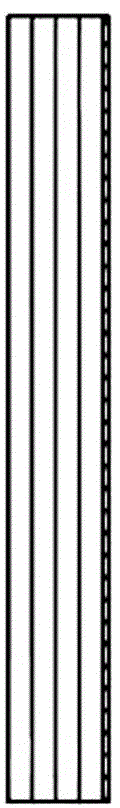

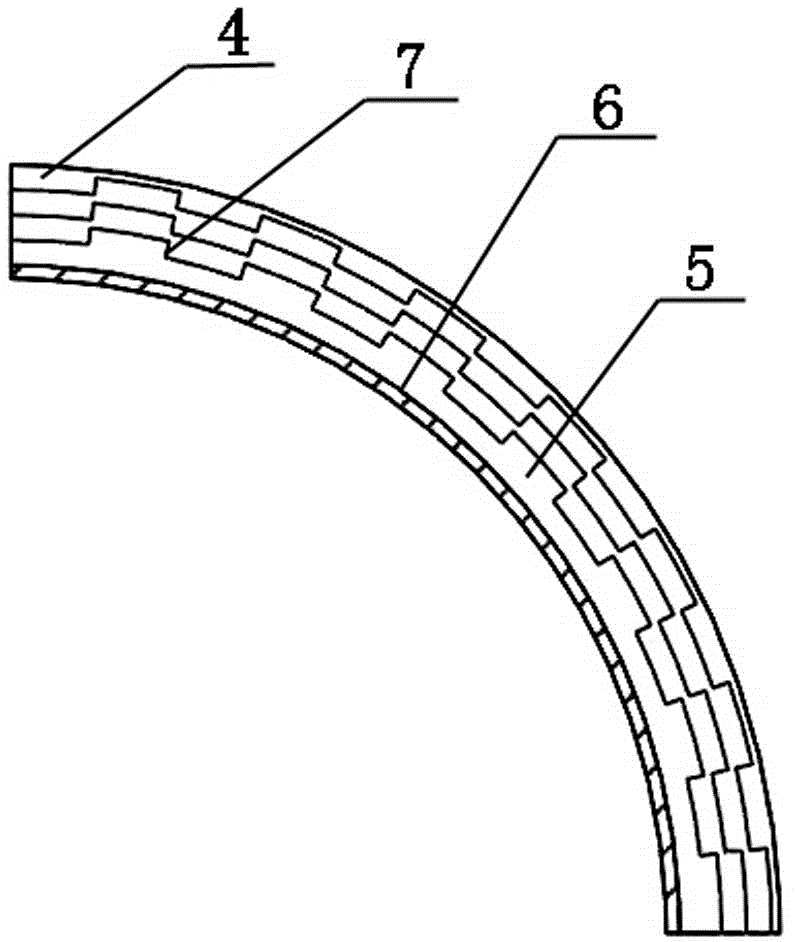

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, the metal reflective heat preservation cover of the present invention mainly includes a metal shell 1 and a built-in heat preservation layer 2, and the metal shell 1 is formed by connecting four side wall panels 3 and an outer wall panel 4 and an inner wall panel 5. A block-shaped casing, in which a layered insulating layer 2 composed of metal foil frame layers is placed.

[0016] What is shown in the figure is a metal reflective heat preservation cover for arc-shaped surface heat preservation. The whole equipment can be covered with multiple metal reflective heat preservation covers to form an integral heat preservation shell or cover body; the outer wall of the present invention The plate 4 and the inner wall plate 5 are correspondingly made into arc-shaped plates, and together with the four side wall plates 3 form an arc-shaped block shell; the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com