Device for sleeving inner and outer tank body of low-temperature container

A low-temperature container, inner and outer tank technology, used in pressure vessels, container filling methods, fixed-capacity gas storage tanks, etc., can solve the problems of small unilateral gap in the interlayer space, and the inner and outer tanks are not easy to fit together, and increase the net load. , The effect of saving welding consumables and labor costs, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

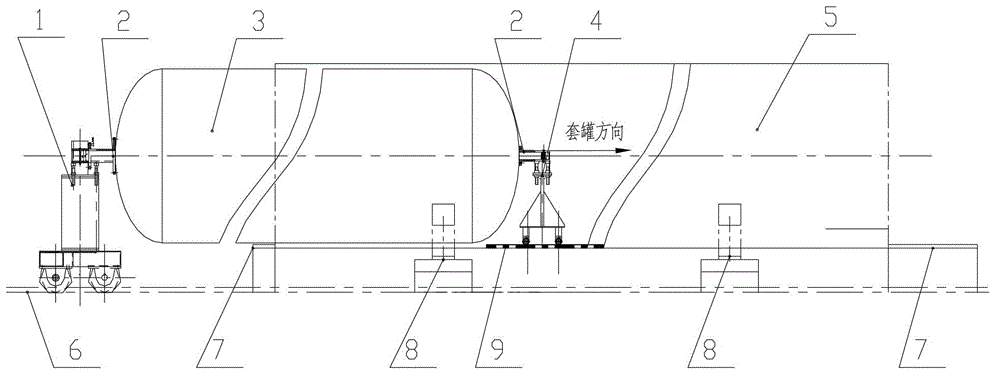

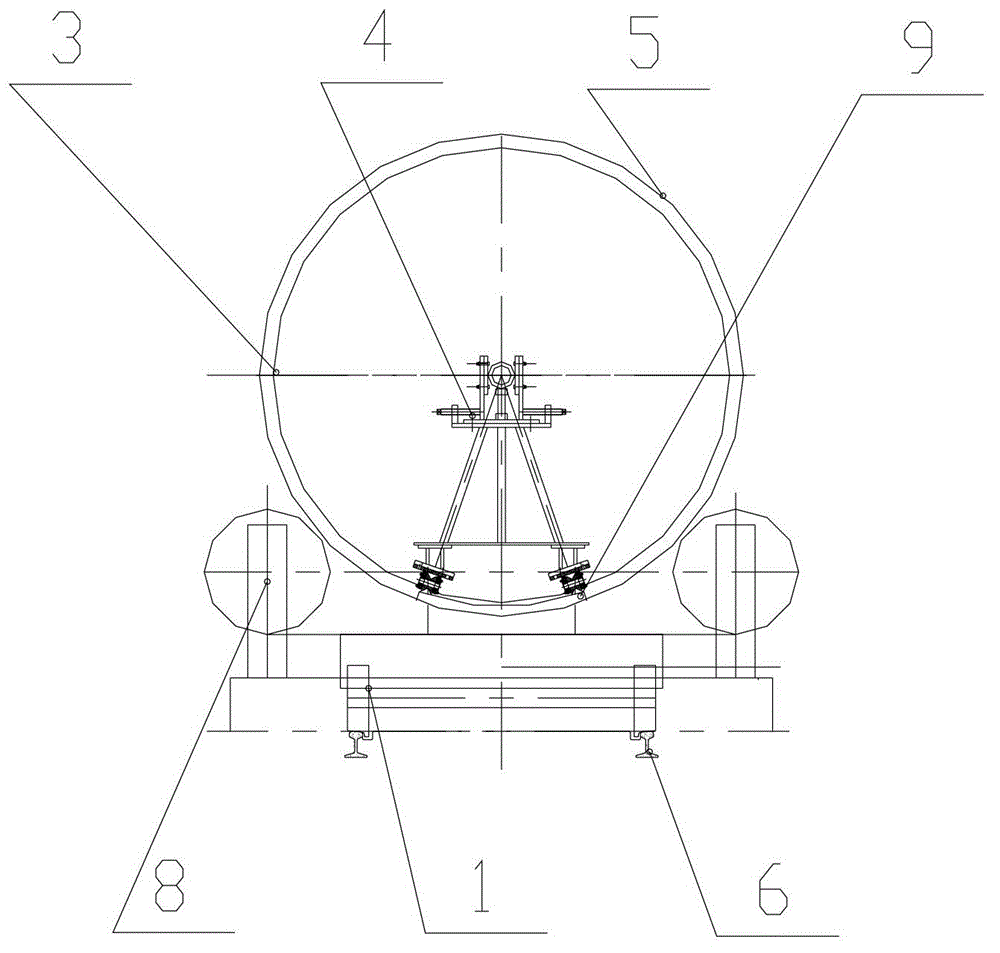

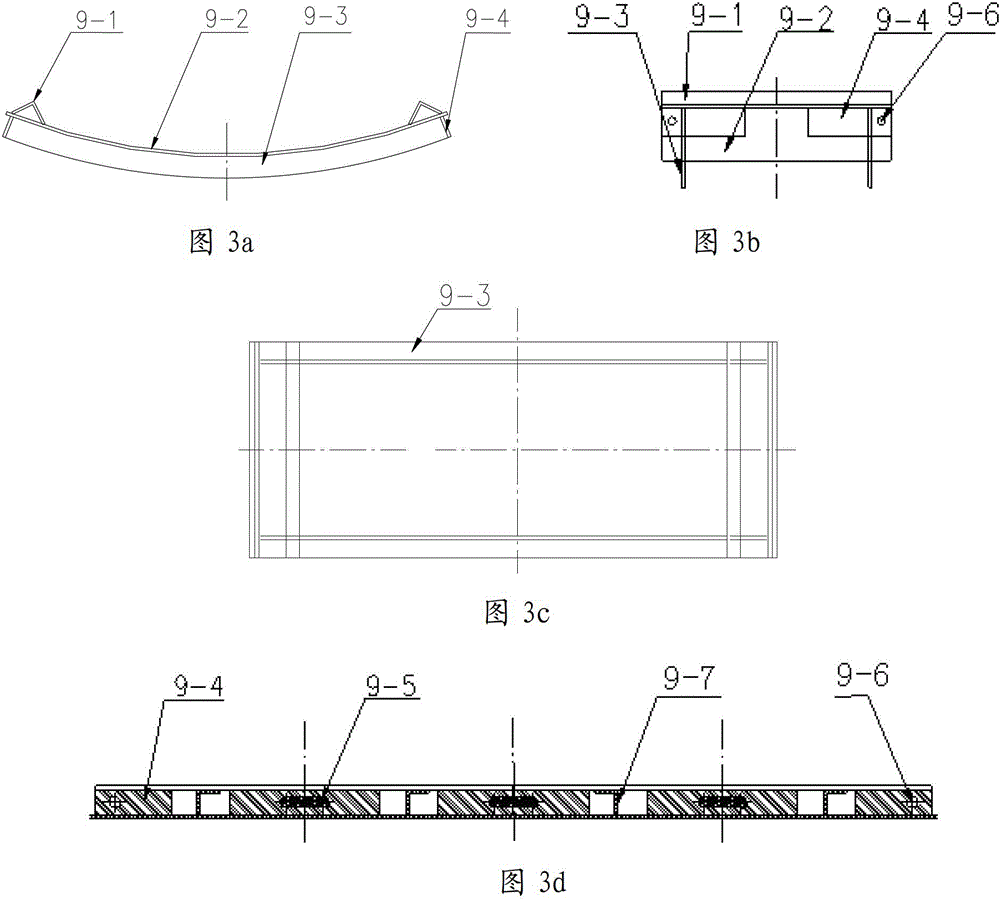

[0035] like figure 1 , figure 2 As shown, the inner and outer tank assembly device of the low-temperature container includes an inner tank body 3, an outer tank body 5, an outer tank body support seat 8, a traction trolley 1 and a tank sleeve trolley 4, and the front and rear ends of the inner tank body 3 are respectively fixed Supported on the can casing trolley 4 and the traction trolley 1; for the traction trolley 1, a traction trolley track 6 is provided below the outer tank body 5; The extension track 7 is flat, and the movable track 9 is arranged in the outer tank body 5 along the path of the extension track 7, and there are at least three movable tracks 9. The outer tank body 5 is provided with a plurality of reinforcing rings 9-7, the length of the movable track 9 is equivalent to the spacing of the reinforcing rings 9-7, and the plurality of movable tracks 9 are sequentially arranged between each reinforcing ring 9-7. The front and rear ends of the inner tank body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com