Material volatility test device in ultra-high vacuum thermal environment

A characteristic testing, ultra-high vacuum technology, applied in the direction of removing certain components and weighing, etc., to achieve the effects of pollution protection, ensuring heating uniformity, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following introduces the specific implementation mode as the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

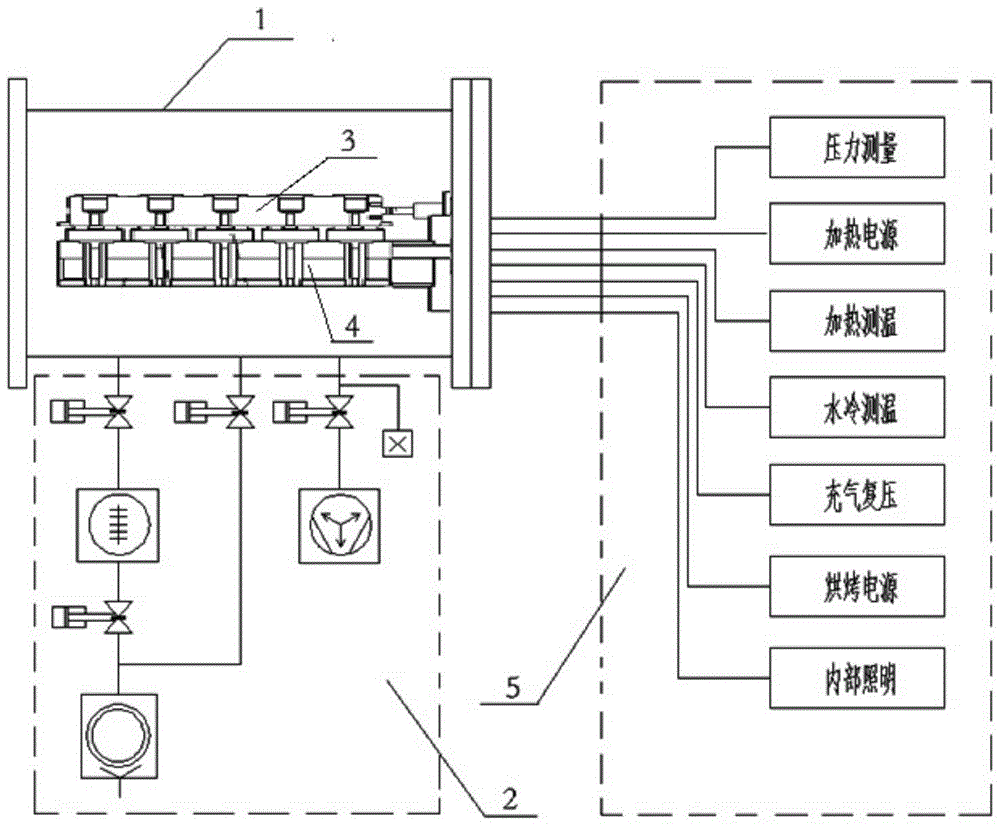

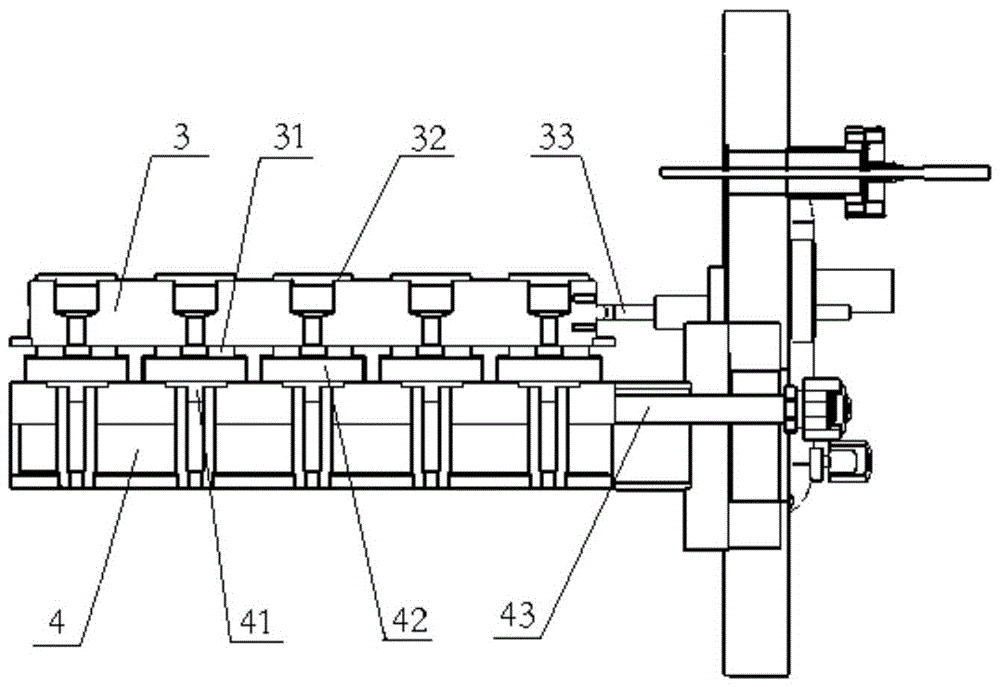

[0021] figure 1 It is a system schematic diagram of the ultra-high vacuum material volatile characteristic testing device. The testing device includes: a test container 1, a vacuum pumping system 2, a heating and temperature control test platform 3, a water-cooled temperature control collection platform 4, and a measurement and control system 5. The test container 1 is a horizontal cylindrical structure of Ф200mm×280mm, made of stainless steel, the surface is polished, and the interface of the test container is sealed with a metal gasket. The test container is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com