Aluminum conductors for automotive wiring

A technology of aluminum wire and wiring, applied in the direction of conductors, insulated conductors, metal/alloy conductors, etc., can solve the problems of increased space occupied by cables, larger gaps between monofilaments, and larger occupied space by cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

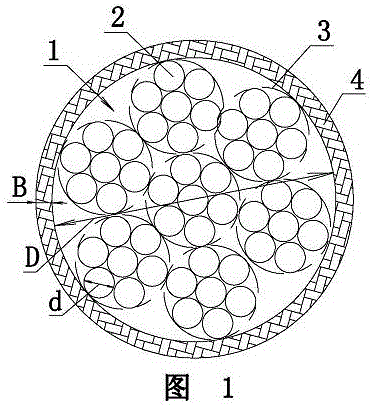

[0022] like figure 1As shown, the cable core 1 is formed by twisting 49 aluminum monofilaments 2 (each black circle in the figure represents an aluminum monofilament), and the aluminum monofilament 2 is made of aluminum alloy. The outer periphery of the cable core 1 is covered with an insulating layer 4, and the cross-sectional outer diameter of each aluminum monofilament 2 is d=0.30mm. Considering the error of monofilament extrusion, the sum of the cross-sectional areas of 49 aluminum monofilaments 2 is ΣS 1 Controlled at 1.25mm 2 —1.15mm 2 Between, so the wire nominal ΣS 1 1.25mm 2 , the structure of the aluminum wire used in automotive signal control lines. The outer diameter of the insulating layer 4 is controlled between 1.70mm-1.90mm, and the inner diameter of the insulating layer 4 is controlled between 1.46mm-1.66mm. This structure is also correspondingly suitable for the outer diameter d of the section of the aluminum monofilament 2 = 0.15mm-0.45mm, and the void ...

Embodiment 2

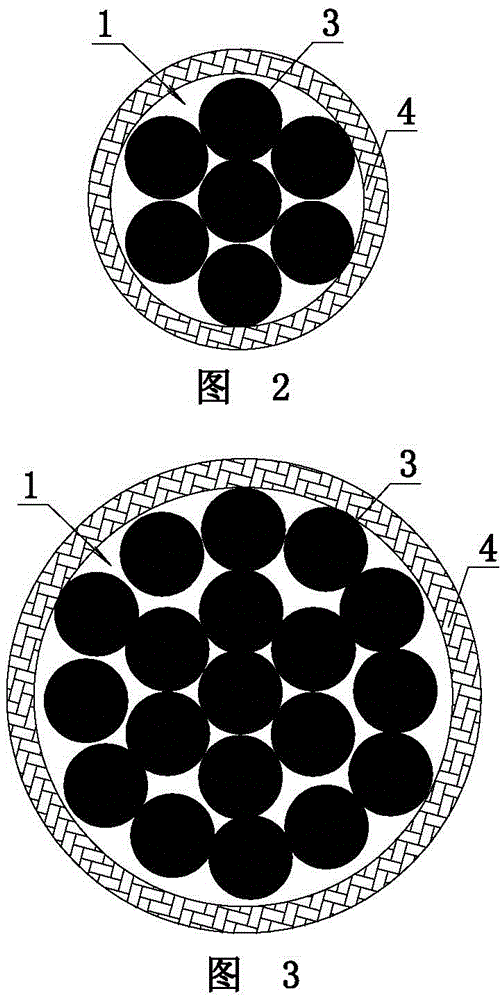

[0024] As shown in Figure 2, the cable core 1 includes 59 aluminum monofilaments (each black dot in the figure represents a strand), the aluminum monofilaments are made of pure aluminum or aluminum alloy, and each aluminum monofilament The outer diameter of the wire d=0.42mm. The cable core 1 adopts a two-layer complex twisted structure. The cable core 1 is twisted and arranged from the inside to the outside with a core strand and an outer strand. The core strand is made of 11 aluminum monofilaments twisted, and the outer strand The lines are all twisted from 8 aluminum monofilaments. The stranding direction of the core strands is leftward (S direction), and the stranding pitch is 45mm; the stranding direction of the outer strands is leftward (S direction), and the stranding pitch is 38mm; There are 6 outer strands twisted around the outer circumference of the strands in the core. The direction of the outer strands is right (Z direction), and the pitch of the strands is 125mm...

Embodiment 3

[0026] As shown in Figure 3, the aluminum conductors for automotive wiring, the cable core 1 includes 1520 aluminum monofilaments (each black dot in the figure represents a strand), the aluminum monofilaments are made of pure aluminum, each The outer diameter of the aluminum monofilament d=0.72mm, the sum of the cross-sectional areas of 1520 aluminum monofilaments ΣS 1 Controlled at 122mm 2 —113mm 2 Between, so the wire nominal ΣS 1 120mm 2 , the outer diameter of the insulating layer 4 is 17.70mm-19.70mm, and the inner diameter of the insulating layer 4 is controlled between 16.40mm-18.50mm. The cable core 1 adopts a three-layer complex twisted structure, and the cable core 1 is twisted and arranged in sequence from the inside to the outside, including core strands, middle strands and outer strands, and each strand includes 80 aluminum monofilaments, forming 1×80+6×80+12×80 cable structure. The core strand is located at the center of the cable core 1. The stranding direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com