Disc rotor motor

A disc rotor and motor technology, applied in the field of disc rotor motors, can solve problems such as small structure space, and achieve the effect of improving efficiency or power density and torque density, high power density and torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

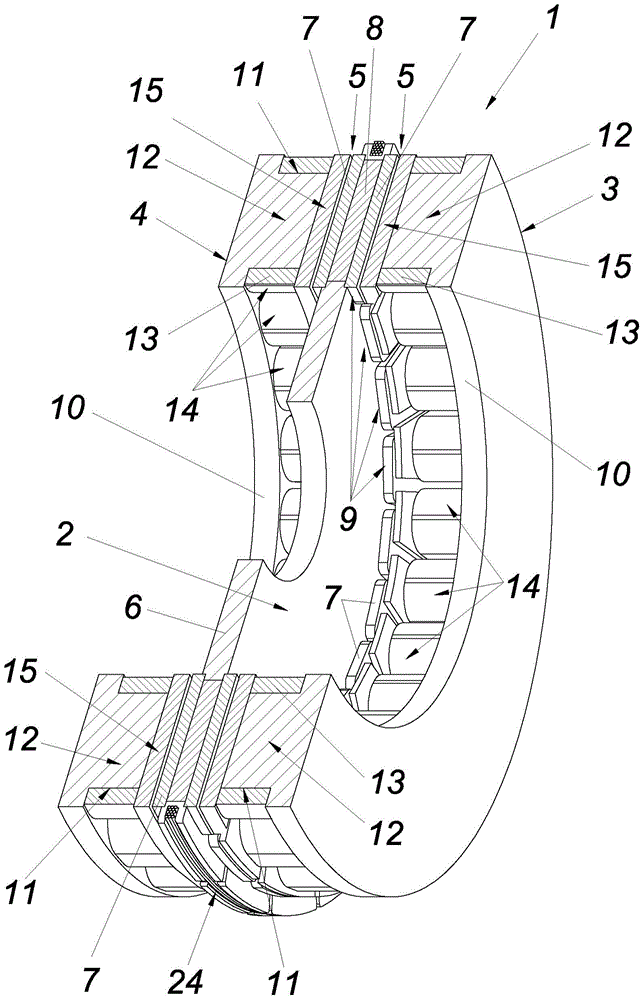

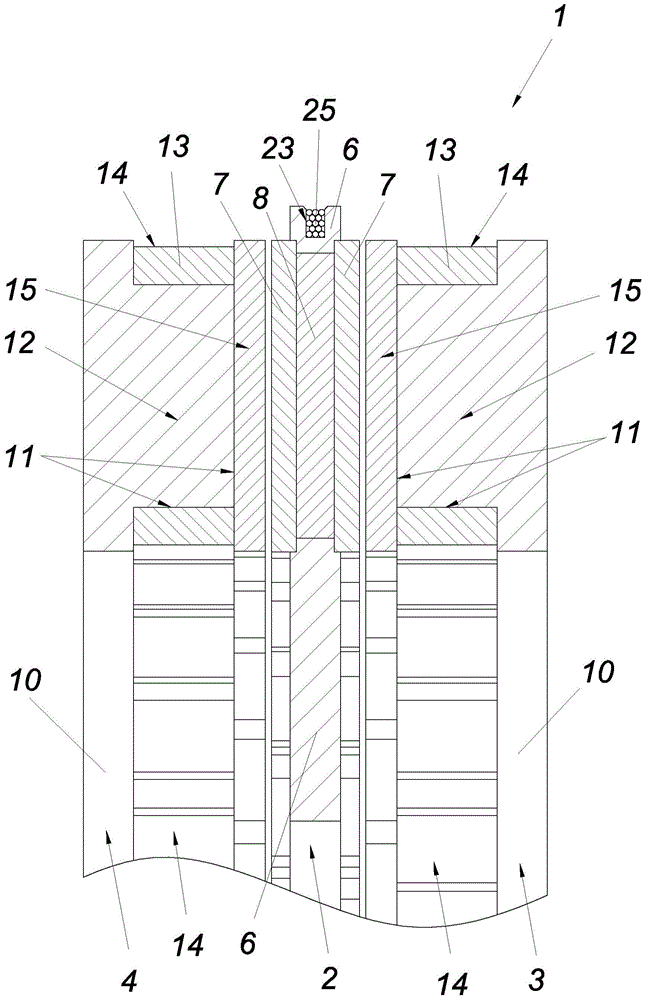

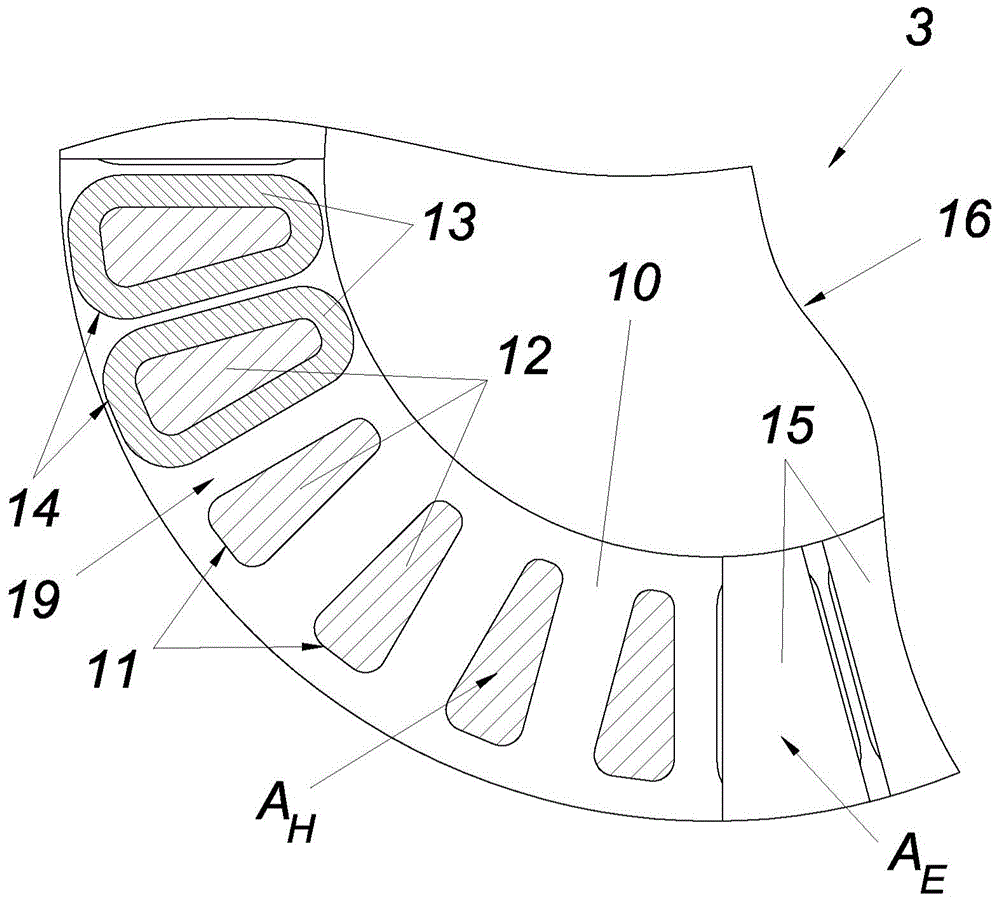

[0033] in accordance with figure 1 In the illustrated exemplary embodiment, a two-sided disk rotor motor 1 is shown, which has a rotor 2 between two identically constructed stators 3 , 4 . The rotor 2 and the stators 3 , 4 are aligned parallel to one another and are each spaced apart from one another by an axial gap 5 . like from figure 1 , 2 As can be seen in FIG. 4 , the rotor 2 has a substantially disk shape formed by its carrier disk 6 . Only ferrite magnets 7 , 8 are arranged on the carrier disk 6 in order to form the magnetic poles 9 which form the permanent magnet torque. It is also conceivable that the magnetic poles 9 contribute to the formation of forces, for example for contactless mounting of the rotor 2 , which is not shown in detail.

[0034] In two identically constructed stators 3 and 4, according to figure 1 In each case, a stator yoke 10 is shown, which ends with a plurality of parallel stator teeth 11 . Stator teeth 11 or tooth necks 12 are wound with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com