An inverter cooling system

A technology of cooling system and frequency converter, which is applied in the field of frequency converter, can solve the problems of uneven heating, difficulty in achieving the effect, high energy consumption of frequency converter, etc., and achieve the effect of rapid and effective cooling and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

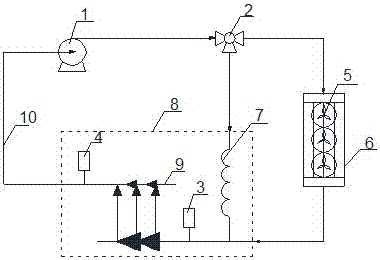

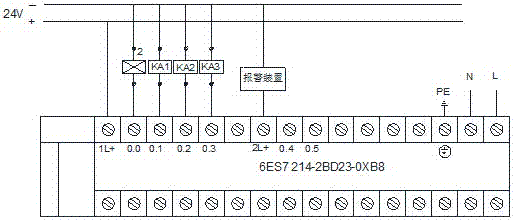

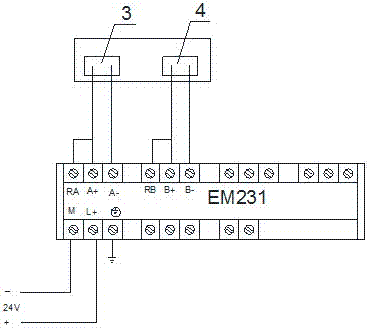

[0017] like figure 1 As shown, the present invention includes a circulating pump 1, an electromagnetic three-way proportional regulating valve 2, a first temperature sensor 3, a second temperature sensor 4, a cooling fan 5, a cooling fin 6, an electric heater 7, a cold plate 9 and a PLC controller , the electric heater 7 and the cold plate 9 are located in the frequency converter 8, the cold plate 9 has a cooling liquid tank, the power module of the frequency converter 8 is installed on the surface of the cold plate 9, and the cooling liquid transfers the heat of the cold plate 9 After being taken away, it flows out of the frequency converter 8 along the coolant circulation channel 10; a first temperature sensor 3 and a second temperature sensor 4 are respectively arranged at the inlet and outlet of the cold plate 9, and when the frequency converter is not started, the first temperature sensor 3 and the second temperature sensor 4 detect the ambient temperature; when the frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com