Single-excitation ultrasonic elliptic-vibration multi-vibrator material conveying device

An elliptical vibration and conveying device technology, which is applied in the directions of vibrating conveyors, conveyors, transportation and packaging, can solve the problems of restricting the overall performance of the precision transmission system, high noise, and complex structure, and simplifies the control circuit and ultrasonic power supply structure. , Broad application prospects, the effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

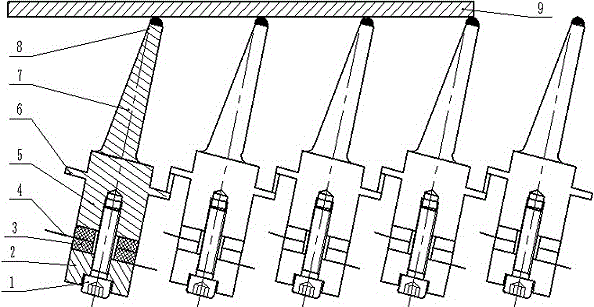

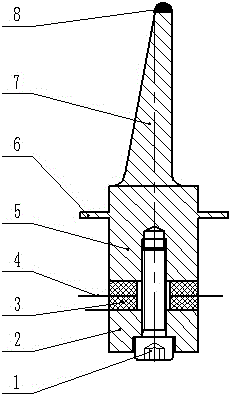

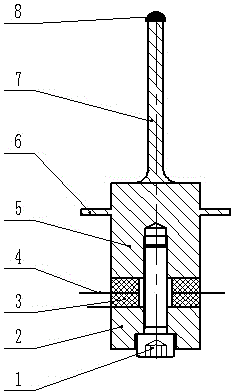

[0020] combine figure 1 , 2 , 3, the single-excitation ultrasonic elliptical vibration multi-vibrator material conveying device uses 5 vibrators as the exciter, and the 5 vibrators are arranged in a straight line and arranged at equal intervals. Each vibrator includes an ultrasonic vibration transducer, an elliptical vibration mode Converter 7 and friction drive block 8; the outer contour of the ultrasonic vibration transducer is cylindrical, which includes a bolt 1 and a rear cover plate 2, a piezoelectric ceramic sheet 3, an electrode sheet 4 and a front cover that are sequentially sleeved on the bolt 1 Plate 5, the front cover 5 is provided with a flange 6 that can be connected with other structural devices, the rear cover 2 and the front cover 5 connect the rear cover 2, the piezoelectric ceramic sheet 3, and the electrode sheet 4 through bolts 1 It is connected and compressed with the front cover plate 5, and constitutes the energy conversion part of the single excitatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com